187HEIDENHAIN TNC 426 B, TNC 430

ú

Number of repetitions Q241: Number of machining

operations on a pitch circle

ú

Set-up clearance Q200 (incremental value): Distance

between tool tip and workpiece surface. Enter a

positive value.

ú

Workpiece surface coordinate Q203 (absolute value):

Coordinate of the workpiece surface

ú

2nd set-up clearance Q204 (incremental value):

Coordinate in the tool axis at which no collision

between tool and workpiece (clamping devices) can

occur.

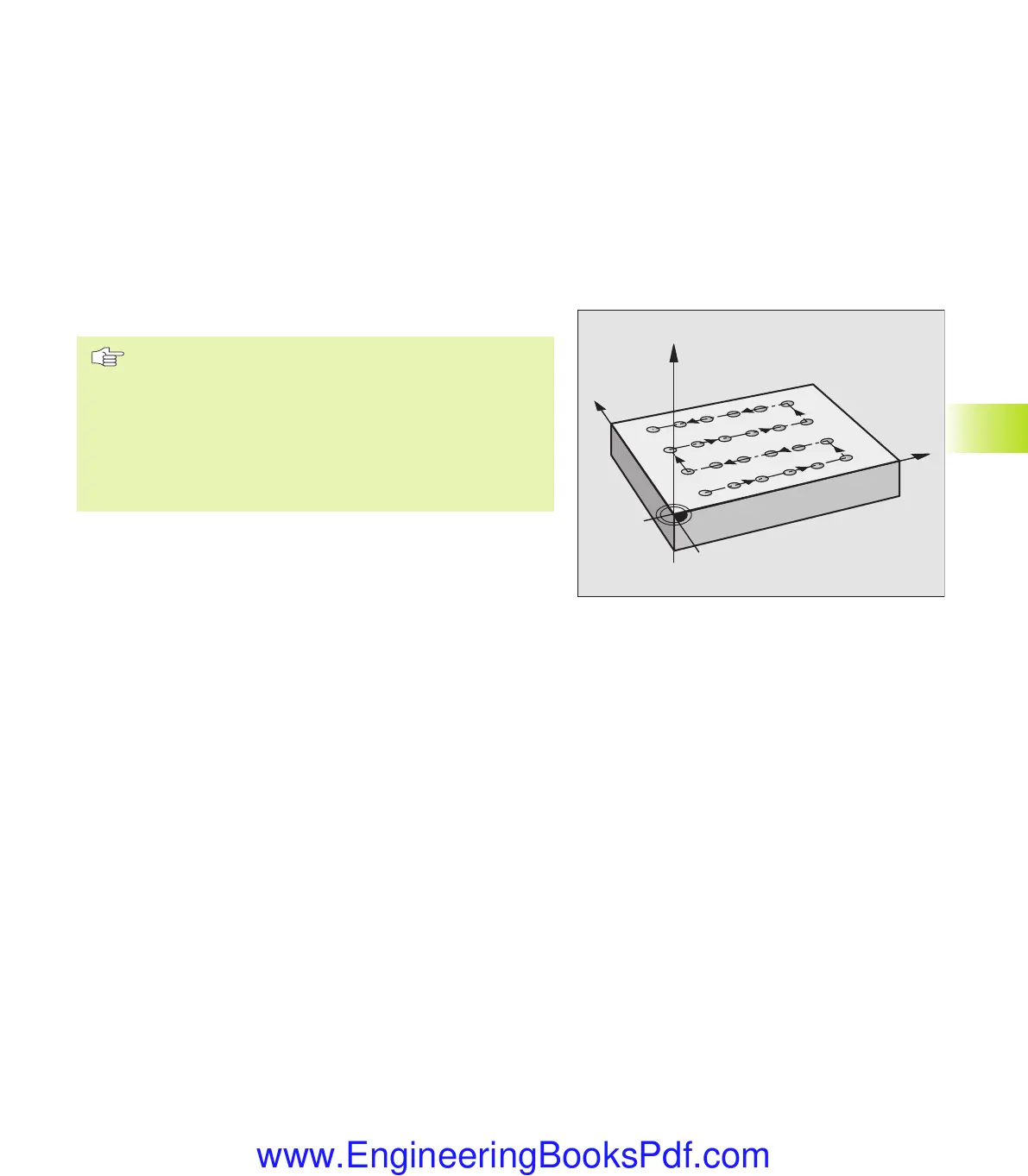

LINEAR PATTERN (Cycle 221)

Before programming, note the following:

Cycle 221 is DEF active, which means that Cycle 221

automatically calls the last defined fixed cycle.

If you combine Cycle 220 with one of the fixed cycles

200 to 204 and 211 to 215, the set-up clearance,

workpiece surface and 2nd set-up clearance that you

defined in Cycle 220 will be effective for the selected

fixed cycle!

1 The TNC automatically moves the tool from its current position to

the starting point for the first machining operation.

The tool is positioned in the following sequence:

■

Move to 2nd set-up clearance (spindle axis)

■ Approach starting point in the working plane

■

Move to set-up clearance above the workpiece surface (spindle

axis)

2 From this position, the TNC executes the last defined fixed cycle.

3 The tool then approaches the starting point for the next

machining operation in the positive main axis direction at set-up

clearance (or 2nd set-up clearance).

4 This process (1 to 3) is repeated until all machining operations on

the first line have been executed. The tool is located above the

last point on the first line.

5 The tool subsequently moves to the last point on the second line

where it carries out the machining operation.

6 From this position, the tool approaches the starting point for the

next machining operation in the negative main axis direction.

7 This process (6) is repeated until all machining operations in the

second line have been executed.

X

Y

Z

8.4 Cycles for Machining Point Patterns

kkap8.pm6 30.06.2006, 07:03187

www.EngineeringBooksPdf.com

Loading...

Loading...