195HEIDENHAIN TNC 426 B, TNC 430

Area of intersection

Only the area overlapped by both

A

and

B

is to be machined. (The

areas covered by

A

or

B

alone are to be left unmachined.)

■

A and

B

must be pockets.

■

A must start inside of

B

.

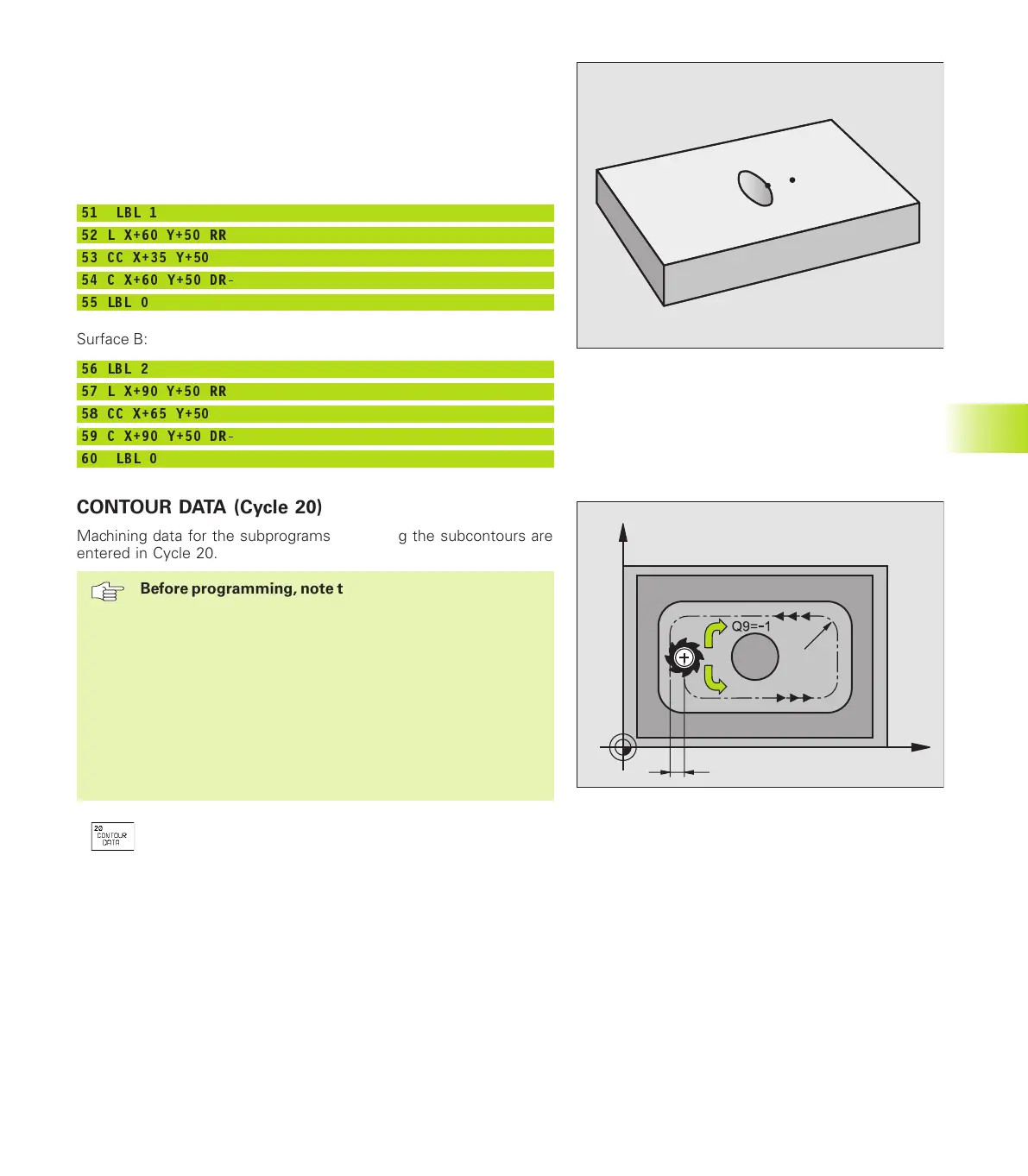

Surface A:

51 LBL 1

52 L X+60 Y+50 RR

53 CC X+35 Y+50

54 C X+60 Y+50 DR-

55 LBL 0

Surface B:

56 LBL 2

57 L X+90 Y+50 RR

58 CC X+65 Y+50

59 C X+90 Y+50 DR-

60 LBL 0

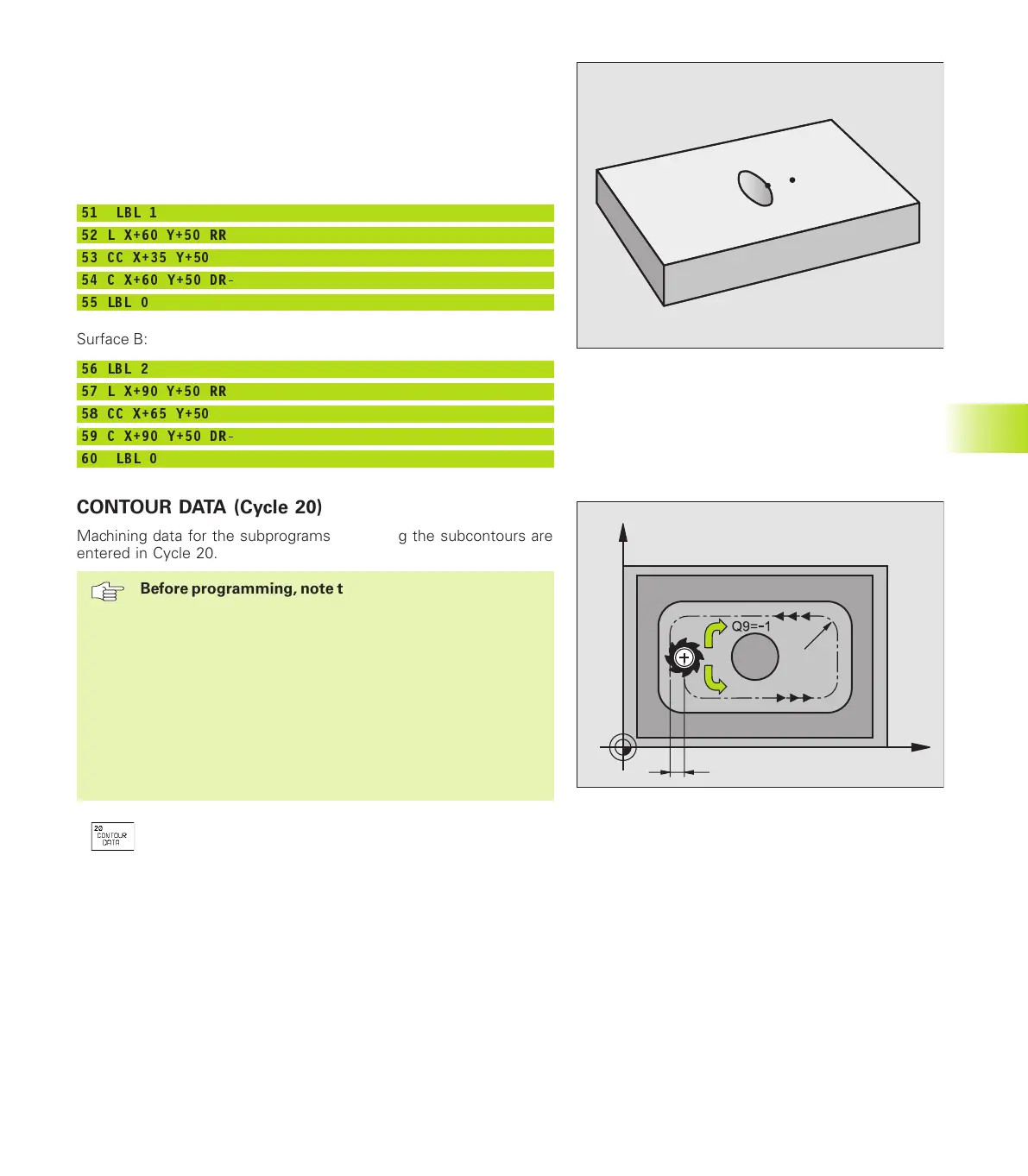

CONTOUR DATA (Cycle 20)

Machining data for the subprograms describing the subcontours are

entered in Cycle 20.

Before programming, note the following:

Cycle 20 is DEF active which means that it becomes

effective as soon as it is defined in the part program.

The algebraic sign for the depth parameter determines

the working direction.

The machining data entered in Cycle 20 are valid for

Cycles 21 to 24.

If you are using the SL cycles in Q parameter programs,

the cycle parameters Q1 to Q19 cannot be used as

program parameters.

ú

Milling depth Q1 (incremental value): Distance

between workpiece surface and pocket floor

ú

Path overlap factor Q2: Q2 x tool radius = stepover

factor k

ú

Finishing allowance for side Q3 (incremental value):

Finishing allowance in the working plane

ú Finishing allowance for floor Q4 (incremental value):

Finishing allowance in the tool axis

ú

Workpiece surface coordinate Q5 (absolute value):

Absolute coordinate of the workpiece surface

8.5 SL Cycles

X

Y

k

Q9=+1

Q8

A

B

kkap8.pm6 30.06.2006, 07:03195

www.EngineeringBooksPdf.com

Loading...

Loading...