8 Programming: Cycles

198

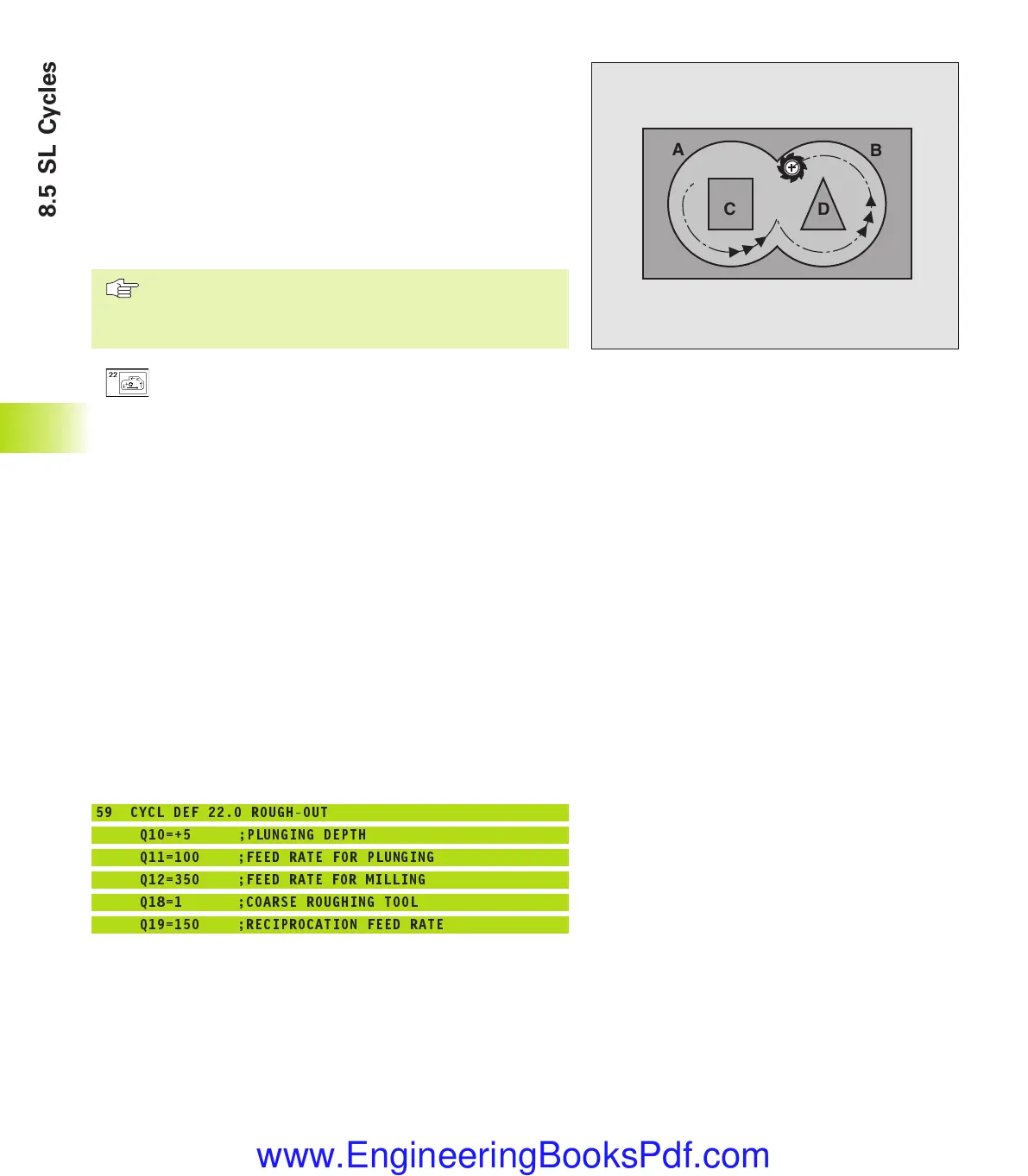

ROUGH-OUT (Cycle 22)

1 The TNC positions the tool over the cutter infeed point, taking the

allowance for side into account.

2 In the first plunging depth, the tool mills the contour from inside

outward at the milling feed rate.

3 First the island contours (

C

and

D

in the figure at right) are rough-

milled until the pocket contour (

A

,

B

) is approached.

4 Then the pocket contour is rough-milled and the tool is retracted

to the clearance height.

Before programming, note the following:

This cycle requires a center-cut end mill (ISO 1641) or

pilot drilling with Cycle 21.

ú

Plunging depth Q10 (incremental value):

Dimension by which the tool plunges in each infeed

ú

Feed rate for plunging Q11: Traversing speed of the

tool in mm/min during penetration

ú

Feed rate for milling Q12: Traversing speed for milling

in mm/min

ú

Coarse roughing tool number Q18: Number of the tool

with which the TNC has already coarse-roughed the

contour. If the contour has not been coarse-roughed,

enter zero. If you enter a value other than 0, the TNC

will only rough-out the portion that could not be

machined with the coarse roughing tool.

If the portion that is to be fine-roughed cannot be

approached from the side, the TNC will mill in a

reciprocating plunge-cut. For this purpose, you must

enter the tooth length LCUTS and the maximum

plunge angle ANGLE of the tool in the tool table

TOOL.T (see Chapter 5.2). The TNC will otherwise

generate an error message.

ú

Reciprocation feed rate Q19: Traversing speed of the

tool in mm/min during reciprocating plunge-cut

Example NC blocks:

59 CYCL DEF 22.0 ROUGH-OUT

Q10=+5 ;PLUNGING DEPTH

Q11=100 ;FEED RATE FOR PLUNGING

Q12=350 ;FEED RATE FOR MILLING

Q18=1 ;COARSE ROUGHING TOOL

Q19=150 ;RECIPROCATION FEED RATE

C

D

A

B

8.5 SL Cycles

kkap8.pm6 30.06.2006, 07:03198

www.EngineeringBooksPdf.com

Loading...

Loading...