233

HEIDENHAIN TNC 426 B, TNC 430

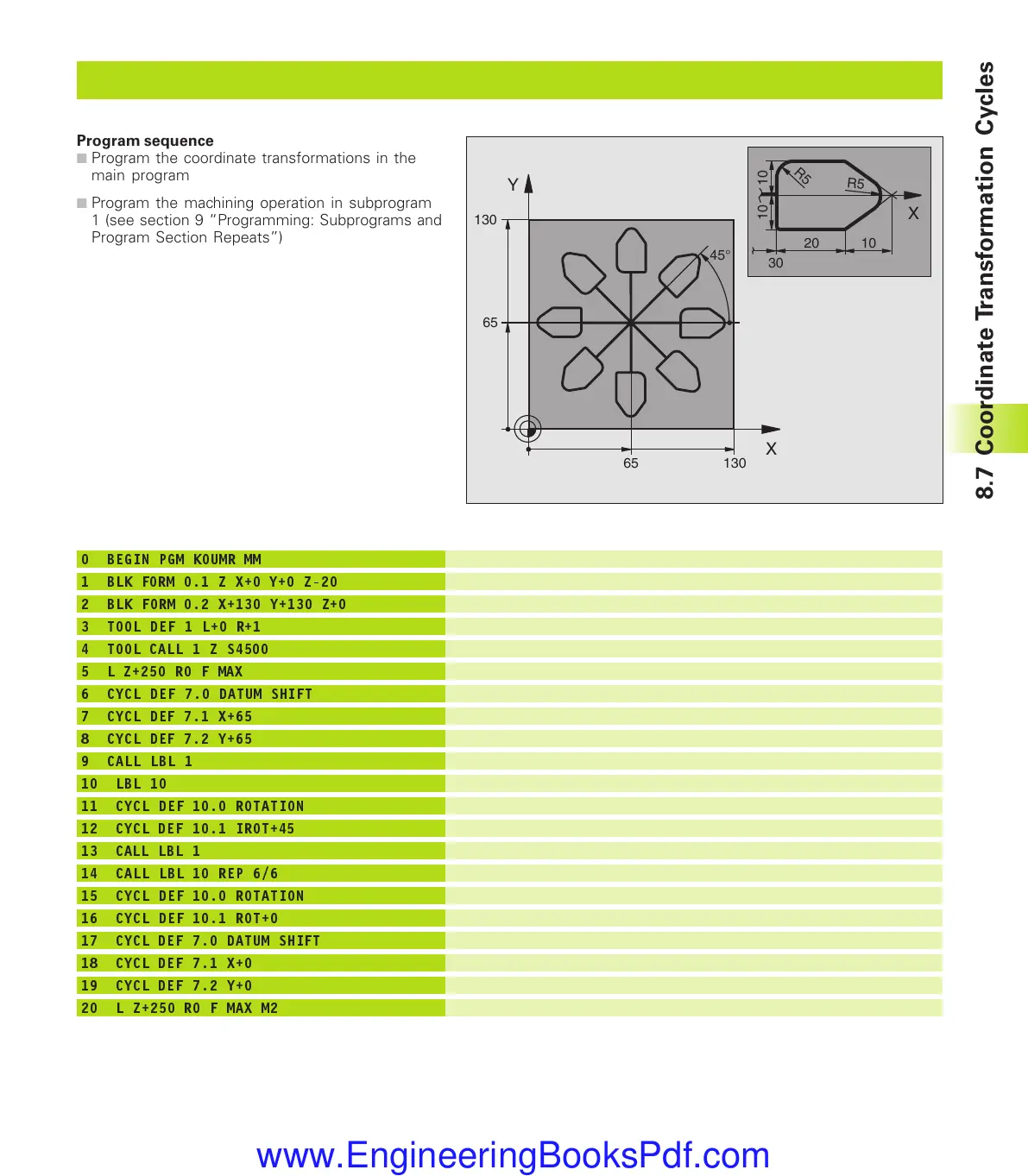

Example: Coordinate transformation cycles

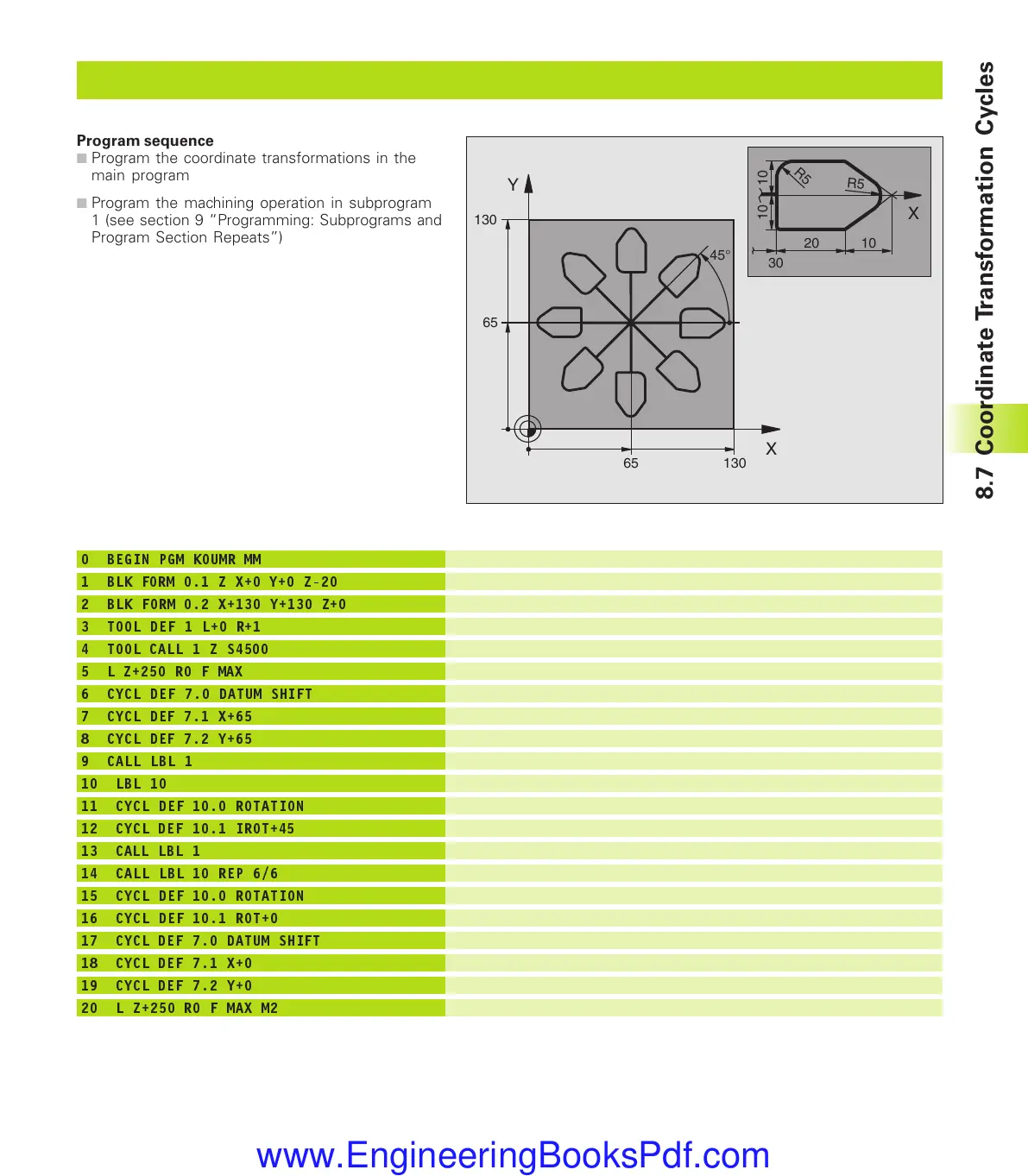

Define the workpiece blank

Define the tool

Call the tool

Retract the tool

Shift datum to center

Call milling operation

Set label for program section repeat

Rotate by 45° (incremental)

Call milling operation

Return jump to LBL 10; execute the milling operation six times

Reset the rotation

Reset the datum shift

Retract in the tool axis, end program

0 BEGIN PGM KOUMR MM

1 BLK FORM 0.1 Z X+0 Y+0 Z-20

2 BLK FORM 0.2 X+130 Y+130 Z+0

3 TOOL DEF 1 L+0 R+1

4 TOOL CALL 1 Z S4500

5 L Z+250 R0 F MAX

6 CYCL DEF 7.0 DATUM SHIFT

7 CYCL DEF 7.1 X+65

8 CYCL DEF 7.2 Y+65

9 CALL LBL 1

10 LBL 10

11 CYCL DEF 10.0 ROTATION

12 CYCL DEF 10.1 IROT+45

13 CALL LBL 1

14 CALL LBL 10 REP 6/6

15 CYCL DEF 10.0 ROTATION

16 CYCL DEF 10.1 ROT+0

17 CYCL DEF 7.0 DATUM SHIFT

18 CYCL DEF 7.1 X+0

19 CYCL DEF 7.2 Y+0

20 L Z+250 R0 F MAX M2

Program sequence

■

Program the coordinate transformations in the

main program

■

Program the machining operation in subprogram

1 (see section 9 “Programming: Subprograms and

Program Section Repeats”)

8.7 Coordinate Transformation Cycles

X

Y

65

65

130

130

45°

X

20

30

10

R5

R5

1010

kkap8.pm6 30.06.2006, 07:04233

www.EngineeringBooksPdf.com

Loading...

Loading...