167

HEIDENHAIN TNC 426 B, TNC 430

Example: Drilling cycles

Define the workpiece blank

Define the tool

Call the tool

Retract the tool

Define THREAD CUTTING cycle

Approach hole 1

Call subprogram 1

Approach hole 2

Call subprogram 1

Retract tool, end of main program

Subprogram 1: Thread cutting

Orient spindle (makes it possible to cut repeatedly)

Tool offset to prevent collision during tool infeed (dependent on

core diameter and tool)

Pre-position in rapid traverse

Move to starting depth

Reset the tool to hole center

Call Cycle 18

Retract tool

End of subprogram 1

0 BEGIN PGM C18 MM

1 BLK FORM 0.1 Z X+0 Y+0 Z-20

2 BLK FORM 0.2 X+100 Y+100 Z+0

3 TOOL DEF 1 L+0 R+6

4 TOOL CALL 1 Z S100

5 L Z+250 R0 F MAX

6 CYCL DEF 18.0 THREAD CUTTING

7 CYCL DEF 18.1 DEPTH +30

8 CYCL DEF 18.2 PITCH -1.75

9 L X+20 Y+20 R0 F MAX

10 CALL LBL 1

11 L X+70 Y+70 R0 F MAX

12 CALL LBL 1

13 L Z+250 R0 F MAX M2

14 LBL 1

15 CYCL DEF 13.0 ORIENTATION

16 CYCL DEF 13.1 ANGLE 0

17 L IX-2 R0 F1000

18 L Z+5 R0 F MAX

19 L Z-30 R0 F1000

20 L IX+2

21 CYCL CALL

22 L Z+5 R0 F MAX

23 LBL 0

24 END PGM C18 MM

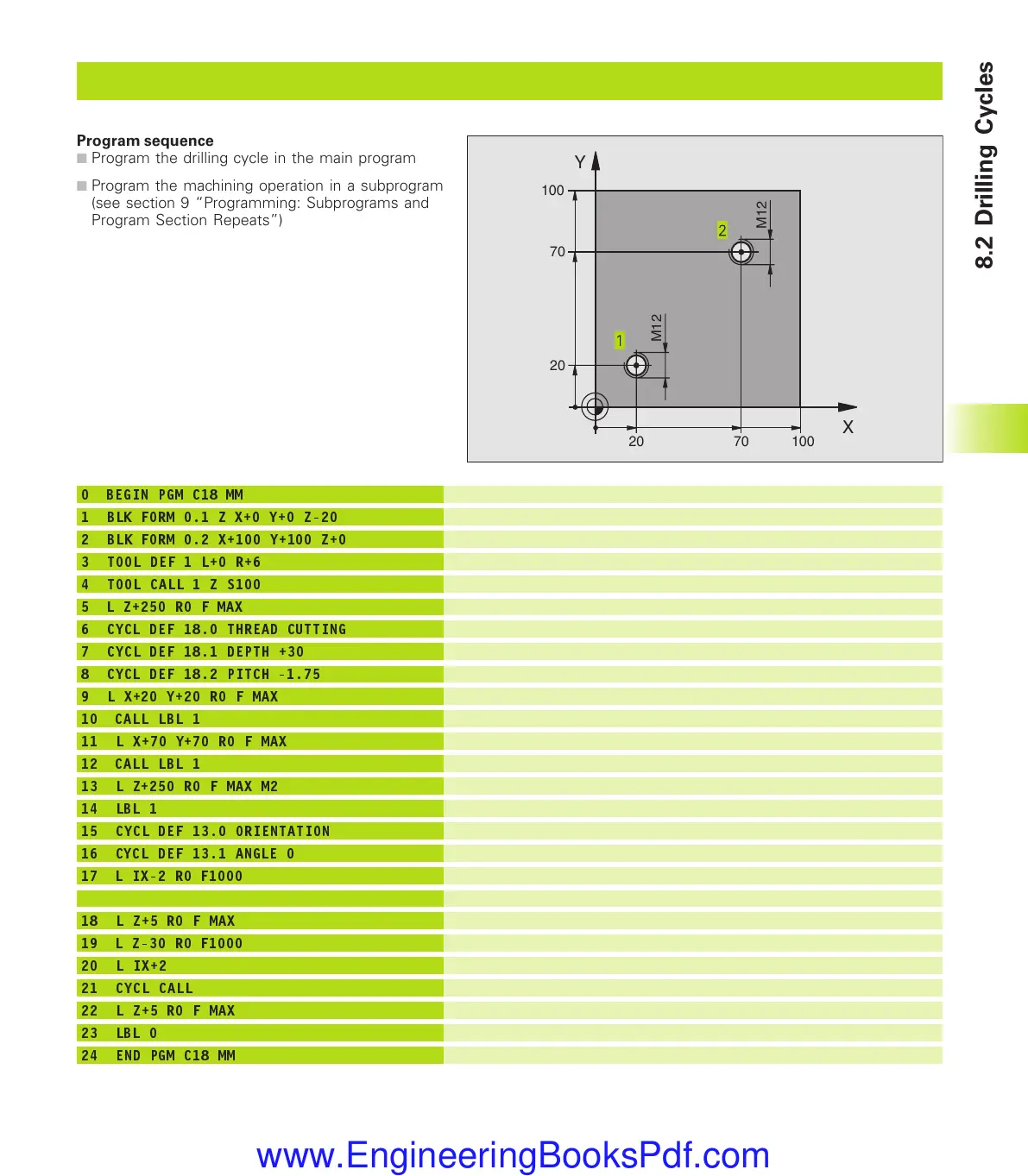

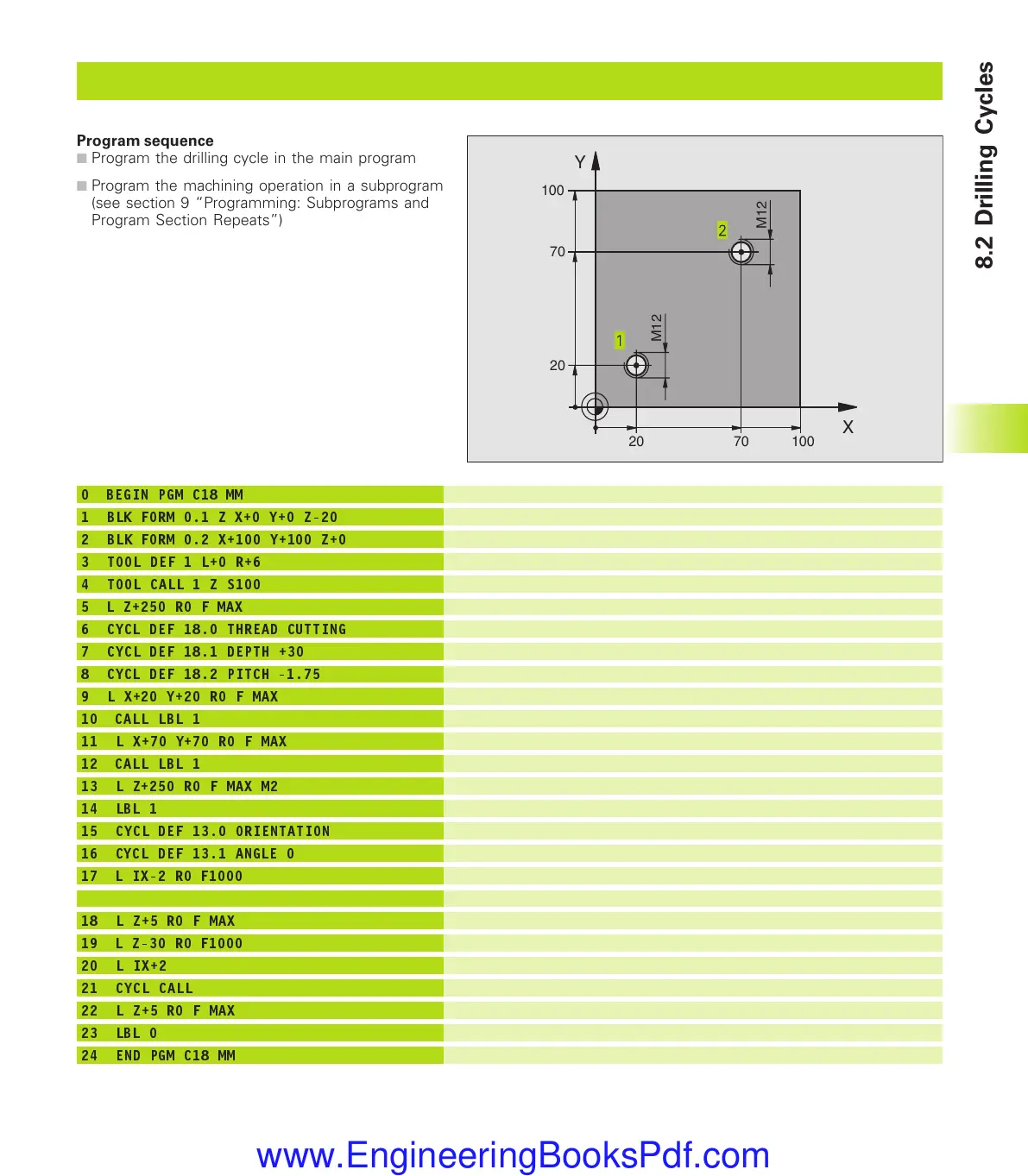

Program sequence

■

Program the drilling cycle in the main program

■

Program the machining operation in a subprogram

(see section 9 “Programming: Subprograms and

Program Section Repeats”)

8.2 Drilling Cycles

X

Y

20

20

100

100

70

70

M12

M12

kkap8.pm6 30.06.2006, 07:03167

www.EngineeringBooksPdf.com

Loading...

Loading...