213HEIDENHAIN TNC 426 B, TNC 430

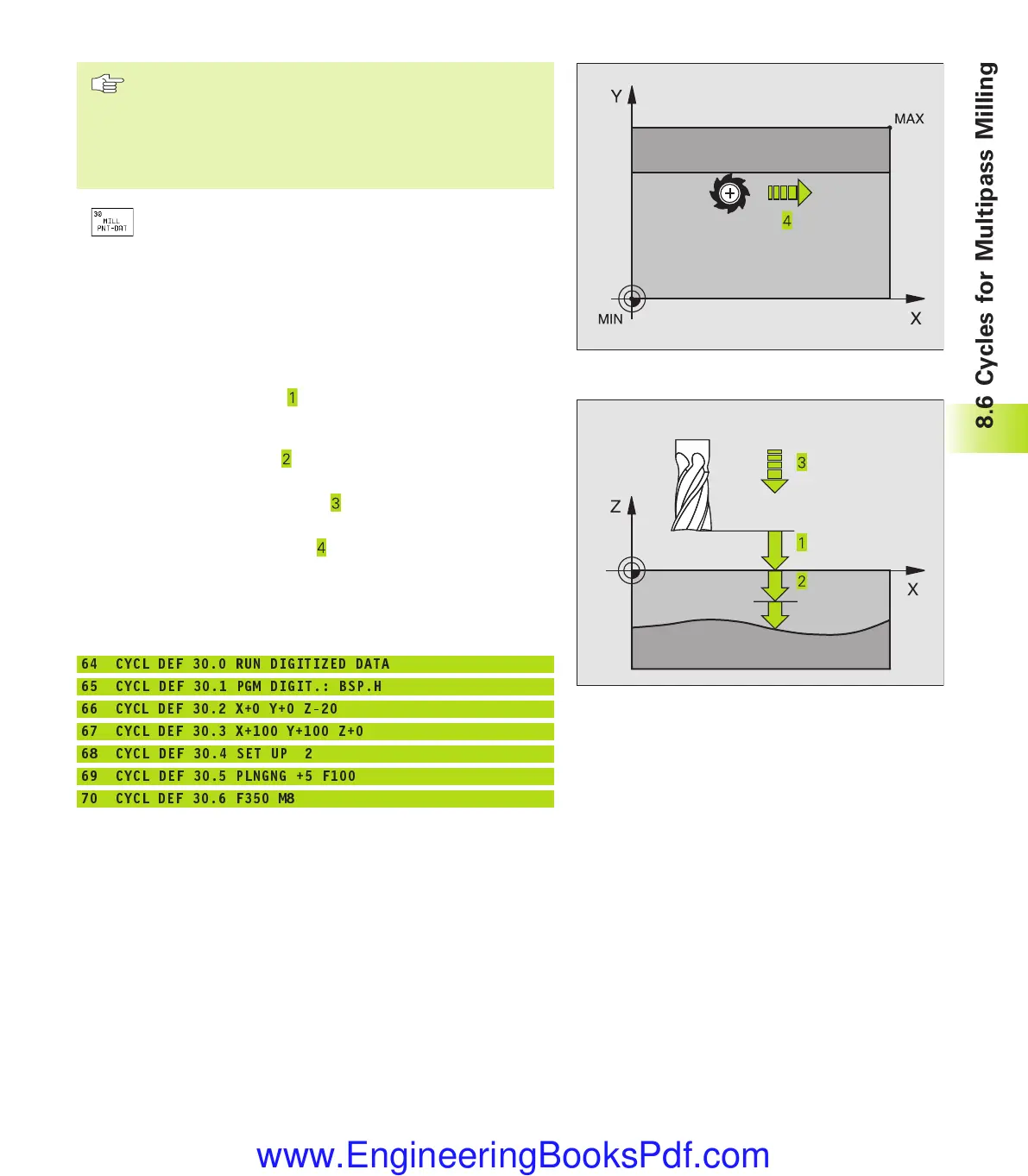

Before programming, note the following:

You can use Cycle 30 to run digitizing data and PNT files.

If you want to run PNT files in which no tool axis

coordinate is programmed, the milling depth is derived

from the programmed MIN point in the tool axis.

ú

PGM Name digitizing data: Enter the name of the file

in which the digitizing data is stored. If the file is not

stored in the current directory, enter the complete

path. If you wish to execute a point table, enter also

the file type .PNT.

ú

Min. point range: Lowest coordinates (X, Y and Z

coordinates) in the range to be milled

ú

Max. point range: Highest coordinates (X, Y and Z

coordinates) in the range to be milled

ú

Setup clearance (incremental value): Distance

between tool tip and workpiece surface for tool

movements in rapid traverse

ú Plunging depth (incremental value): Dimension by

which the tool is advanced in each infeed

ú

Feed rate for plunging : Traversing speed of the tool

in mm/min during penetration

ú

Feed rate for milling : Traversing speed of the tool in

mm/min while milling

ú

Miscellaneous function M: Optional entry of a

miscellaneous function, for example M13

Example NC blocks:

64 CYCL DEF 30.0 RUN DIGITIZED DATA

65 CYCL DEF 30.1 PGM DIGIT.: BSP.H

66 CYCL DEF 30.2 X+0 Y+0 Z-20

67 CYCL DEF 30.3 X+100 Y+100 Z+0

68 CYCL DEF 30.4 SET UP 2

69 CYCL DEF 30.5 PLNGNG +5 F100

70 CYCL DEF 30.6 F350 M8

X

Z

8.6 Cycles for Multipass Milling

kkap8.pm6 30.06.2006, 07:03213

www.EngineeringBooksPdf.com

Loading...

Loading...