101HEIDENHAIN TNC 426 B, TNC 430

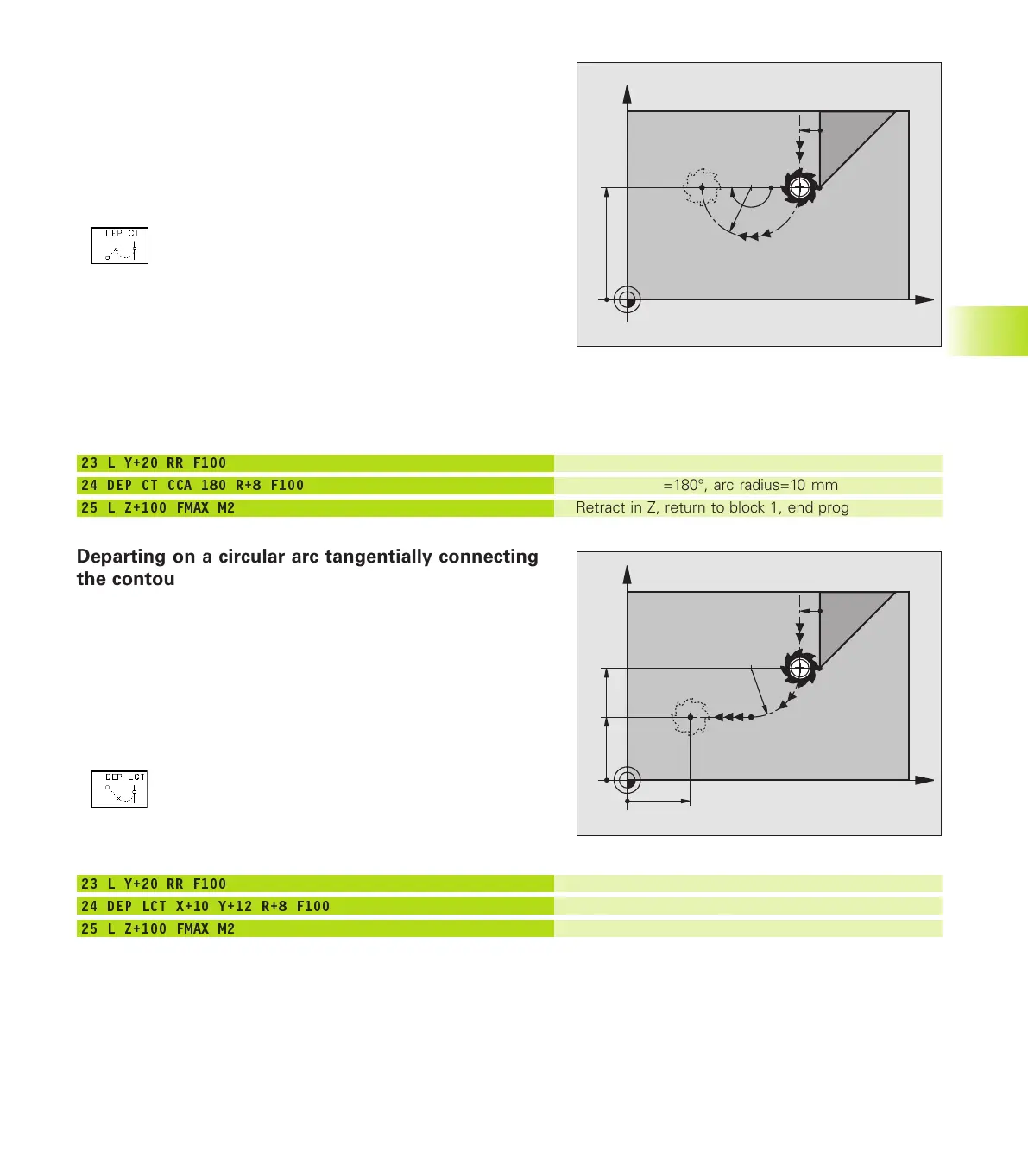

Departing tangentially on a circular arc: DEP CT

The tool moves on a circular arc from the last contour point P

E

to

the end point P

N

. The arc is tangentially connected to the last

contour element.

ú Program the last contour element with the end point P

E

and

radius compensation.

ú

Initiate the dialog with the APPR/DEP key and DEP CT soft key:

ú Radius R of the circular arc

■

If the tool should depart the workpiece in the direction

of the radius compensation (i.e. to the right with RR or

to the left with RL):

Enter R as a positive value.

■

If the tool should depart the workpiece on the

direction opposite to the radius compensation:

Enter R as a negative value.

ú

Center angle CCA of the arc

Example NC blocks

23 L Y+20 RR F100

24 DEP CT CCA 180 R+8 F100

25 L Z+100 FMAX M2

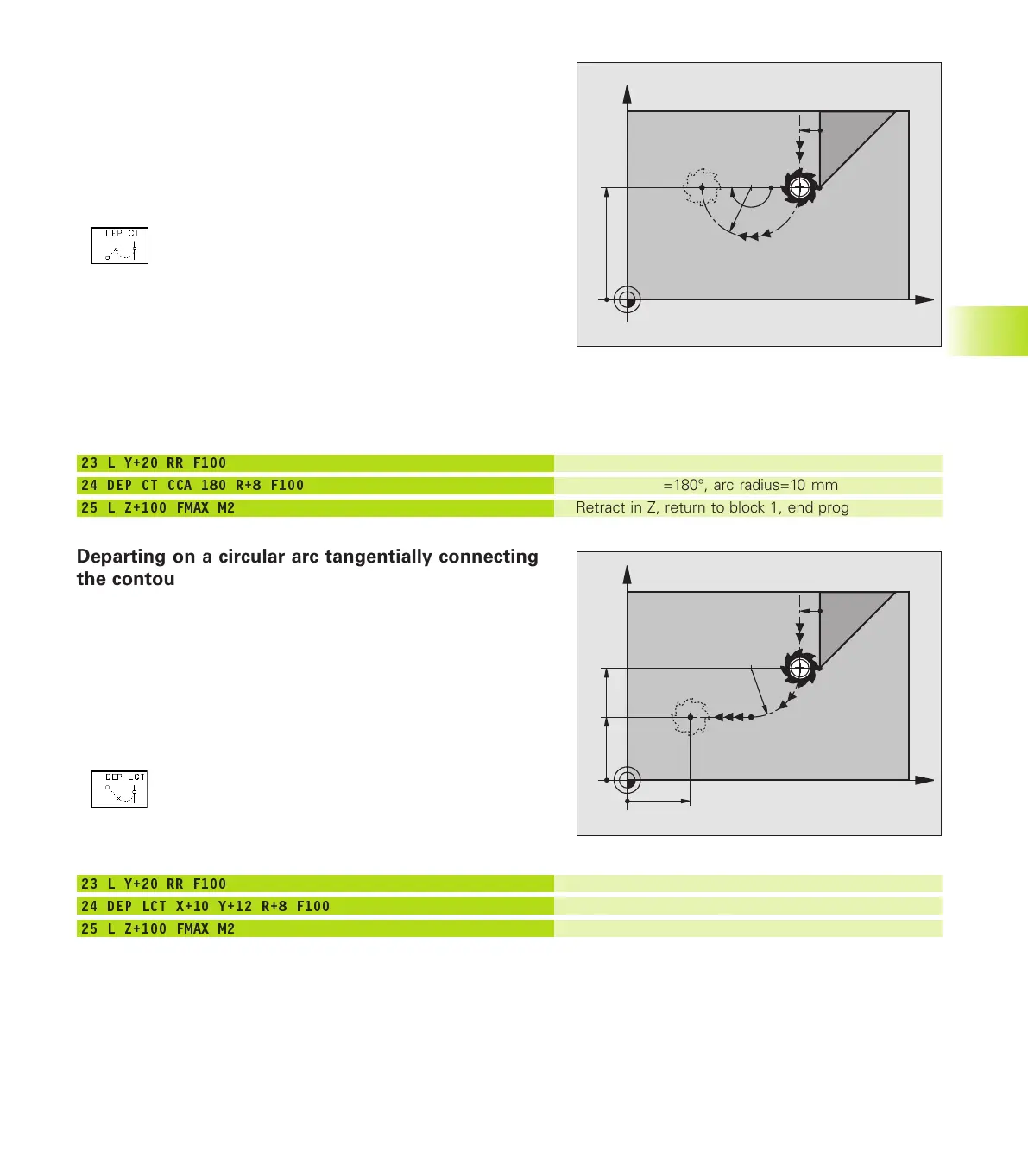

Departing on a circular arc tangentially connecting

the contour and a straight line: DEP LCT

The tool moves on a circular arc from the last contour point P

E

to an

auxiliary point P

H

. It then moves on a straight line to the end point P

N

.

The arc is tangentially connected both to the last contour element

and to the line from P

H

to P

N

. Once these lines are known, the radius

R then suffices to completely define the tool path.

ú Program the last contour element with the end point P

E

and

radius compensation.

ú

Initiate the dialog with the APPR/DEP key and DEP LCT soft key:

ú Enter the coordinates of the end point P

N

.

ú

Radius R of the arc

Always enter R as a positive value

Example NC blocks

23 L Y+20 RR F100

24 DEP LCT X+10 Y+12 R+8 F100

25 L Z+100 FMAX M2

Last contour element: P

E

with radius compensation

Center angle=180°, arc radius=10 mm

Retract in Z, return to block 1, end program

Last contour element: P

E

with radius compensation

Coordinates P

N

, arc radius = 10 mm

Retract in Z, return to block 1, end program

X

Y

20

P

N

R0

P

E

RR

R8

180°

RR

X

Y

20

P

N

R0

P

E

RR

RR

12

10

R8

P

H

R0

6.3 Contour Approach and Departure

Gkap6.pm6 30.06.2006, 07:04101

www.EngineeringBooksPdf.com

Loading...

Loading...