8 Programming: Cycles

158

BORING (Cycle 202)

Machine and control must be specially prepared by the

machine tool builder to enable Cycle 202.

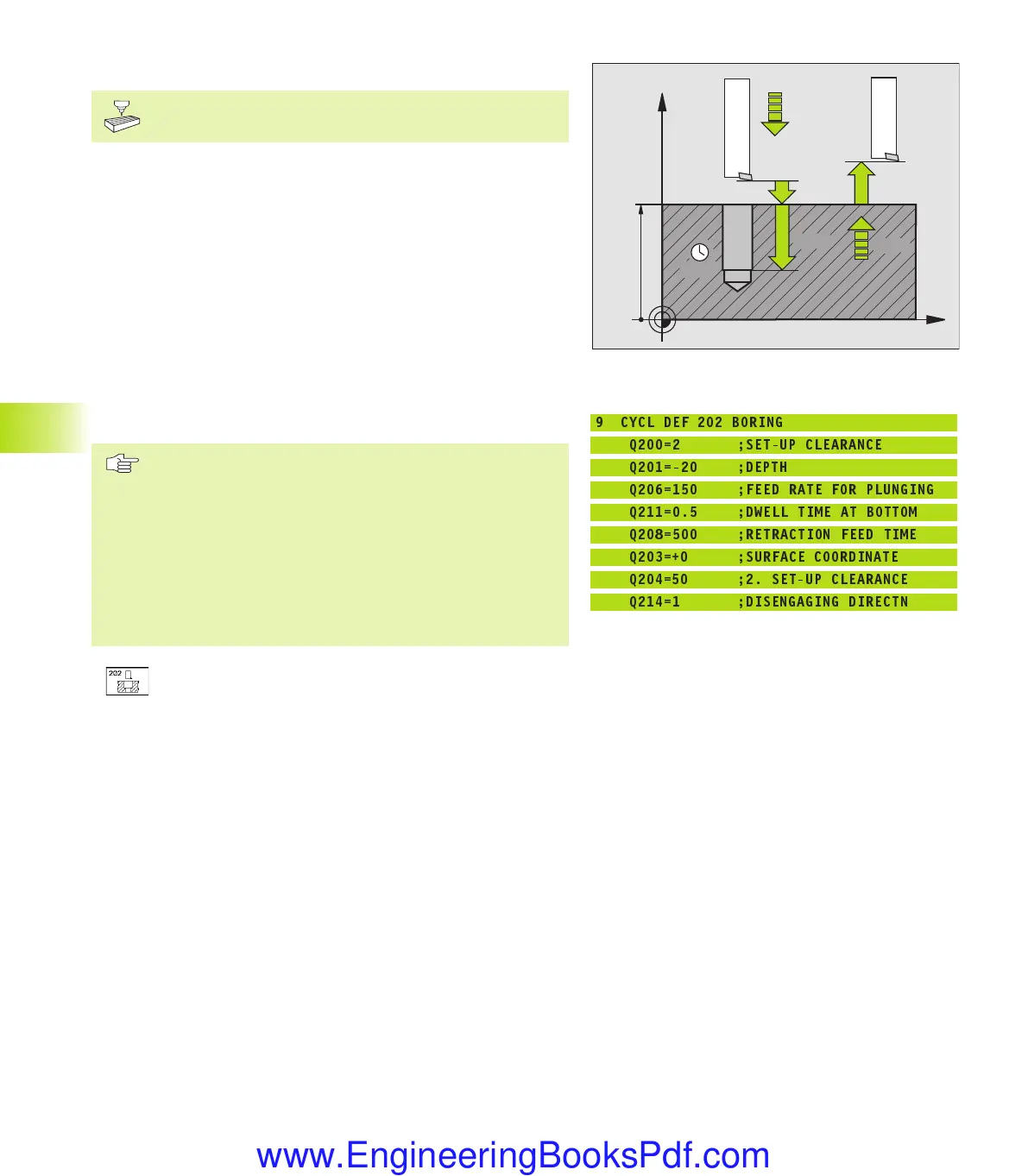

1 The TNC positions the tool in the tool axis at rapid traverse FMAX

to set-up clearance above the workpiece surface.

2 The tool drills to the programmed depth at the feed rate for

plunging.

3 If programmed, the tool remains at the hole bottom for the

entered dwell time with active spindle rotation for cutting free.

4 The TNC then orients the spindle to the 0° position

with an oriented spindle stop.

5 If retraction is selected, the tool retracts in the programmed

direction by 0.2 mm (fixed value).

6 The tool then retracts to set-up clearance at the retraction feed

rate, and from there — if programmed — to the 2nd set-up

clearance in FMAX.

Before programming, note the following:

Program a positioning block for the starting point (hole

center) in the working plane with RADIUS

COMPENSATION R0.

The algebraic sign for the cycle parameter TOTAL HOLE

DEPTH determines the working direction.

After the cycle is completed, the TNC restores the

coolant and spindle conditions that were active before

the cycle call.

ú

Set-up clearance Q200 (incremental value): Distance

between tool tip and workpiece surface.

ú Depth Q201 (incremental value): Distance between

workpiece surface and bottom of hole

ú

Feed rate for plunging Q206: Traversing speed of the

tool during boring in mm/min

ú

Dwell time at depth Q211: Time in seconds that the

tool remains at the hole bottom

ú

Retraction feed rate Q208: Traversing speed of the

tool in mm/min when retracting from the hole. If you

enter Q208 = 0, the tool retracts at feed rate for

plunging.

ú

Workpiece surface coordinate Q203 (absolute value):

Coordinate of the workpiece surface

ú 2nd set-up clearance Q204 (incremental value):

Coordinate in the tool axis at which no collision

between tool and workpiece (clamping devices) can

occur.

X

Z

Q200

Q201

Q206

Q211

Q203

Q204

Q208

8.2 Drilling Cycles

Example NC blocks:

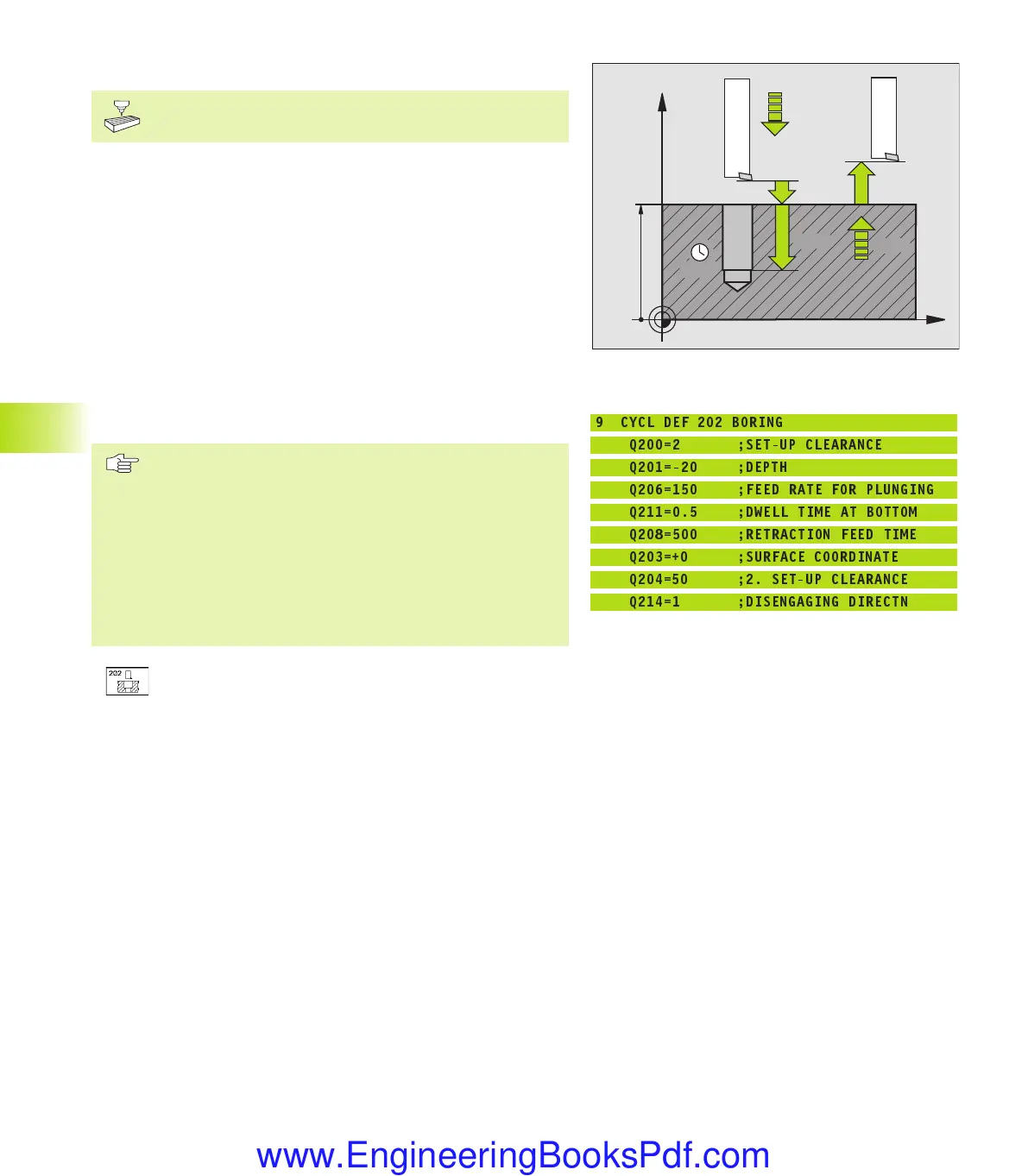

9 CYCL DEF 202 BORING

Q200=2 ;SET-UP CLEARANCE

Q201=-20 ;DEPTH

Q206=150 ;FEED RATE FOR PLUNGING

Q211=0.5 ;DWELL TIME AT BOTTOM

Q208=500 ;RETRACTION FEED TIME

Q203=+0 ;SURFACE COORDINATE

Q204=50 ;2. SET-UP CLEARANCE

Q214=1 ;DISENGAGING DIRECTN

kkap8.pm6 30.06.2006, 07:03158

www.EngineeringBooksPdf.com

Loading...

Loading...