10 Programming: Q Parameters

276

Example: Ellipse

10.11 Programming Examples

Example: Ellipse

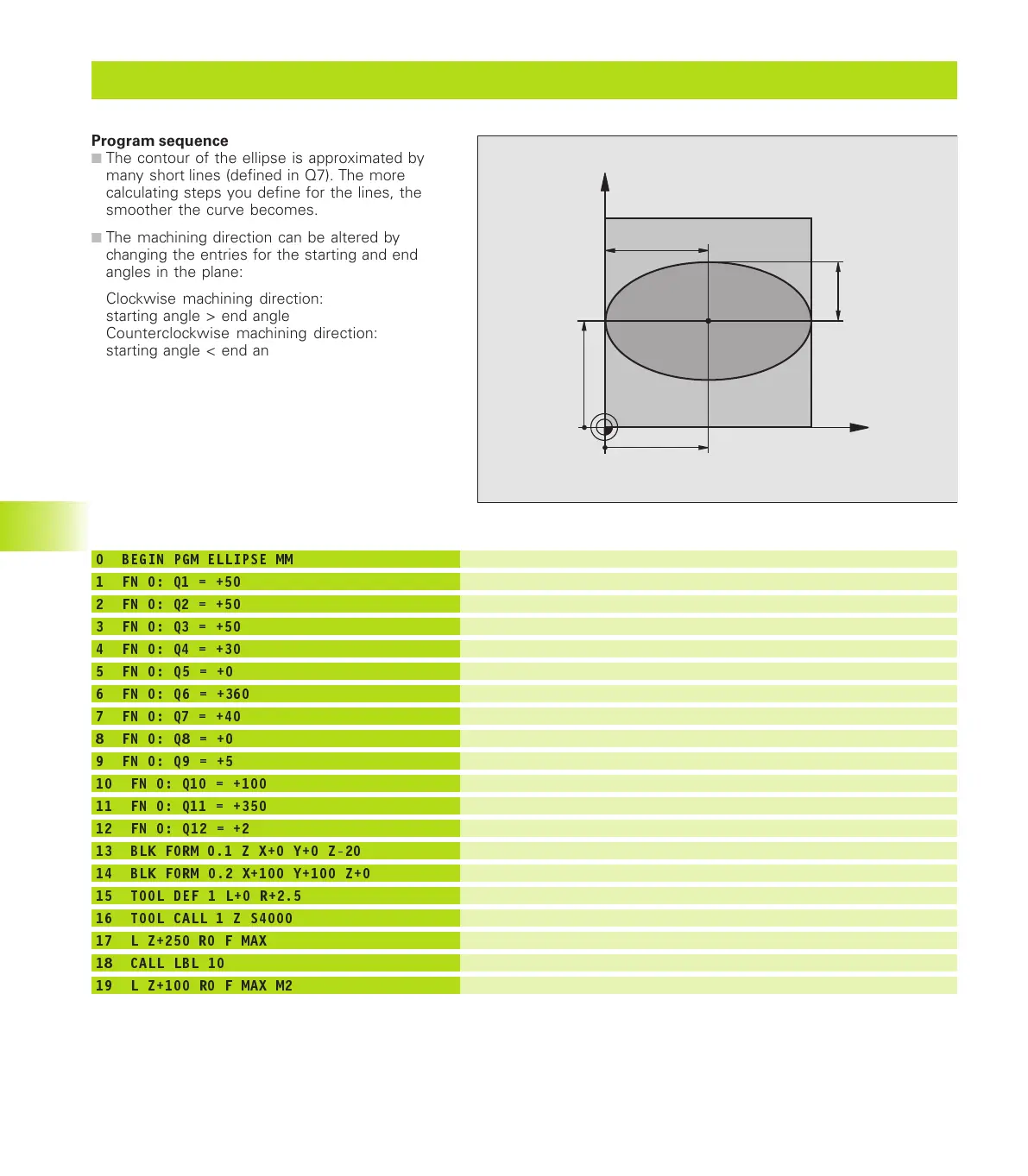

Center in X axis

Center in Y axis

Semiaxis in X

Semiaxis in Y

Starting angle in the plane

End angle in the plane

Number of calculating steps

Rotational position of the ellipse

Milling depth

Feed rate for plunging

Feed rate for milling

Setup clearance for pre-positioning

Define the workpiece blank

Define the tool

Call the tool

Retract the tool

Call machining operation

Retract in the tool axis, end program

0 BEGIN PGM ELLIPSE MM

1 FN 0: Q1 = +50

2 FN 0: Q2 = +50

3 FN 0: Q3 = +50

4 FN 0: Q4 = +30

5 FN 0: Q5 = +0

6 FN 0: Q6 = +360

7 FN 0: Q7 = +40

8 FN 0: Q8 = +0

9 FN 0: Q9 = +5

10 FN 0: Q10 = +100

11 FN 0: Q11 = +350

12 FN 0: Q12 = +2

13 BLK FORM 0.1 Z X+0 Y+0 Z-20

14 BLK FORM 0.2 X+100 Y+100 Z+0

15 TOOL DEF 1 L+0 R+2.5

16 TOOL CALL 1 Z S4000

17 L Z+250 R0 F MAX

18 CALL LBL 10

19 L Z+100 R0 F MAX M2

Program sequence

■

The contour of the ellipse is approximated by

many short lines (defined in Q7). The more

calculating steps you define for the lines, the

smoother the curve becomes.

■

The machining direction can be altered by

changing the entries for the starting and end

angles in the plane:

Clockwise machining direction:

starting angle > end angle

Counterclockwise machining direction:

starting angle < end angle

■

The tool radius is not taken into account.

X

Y

50

50

30

50

MKAP10.PM6 30.06.2006, 07:04276

www.EngineeringBooksPdf.com

Loading...

Loading...