117HEIDENHAIN TNC 426 B, TNC 430

6.5 Path Contours — Polar Coordinates

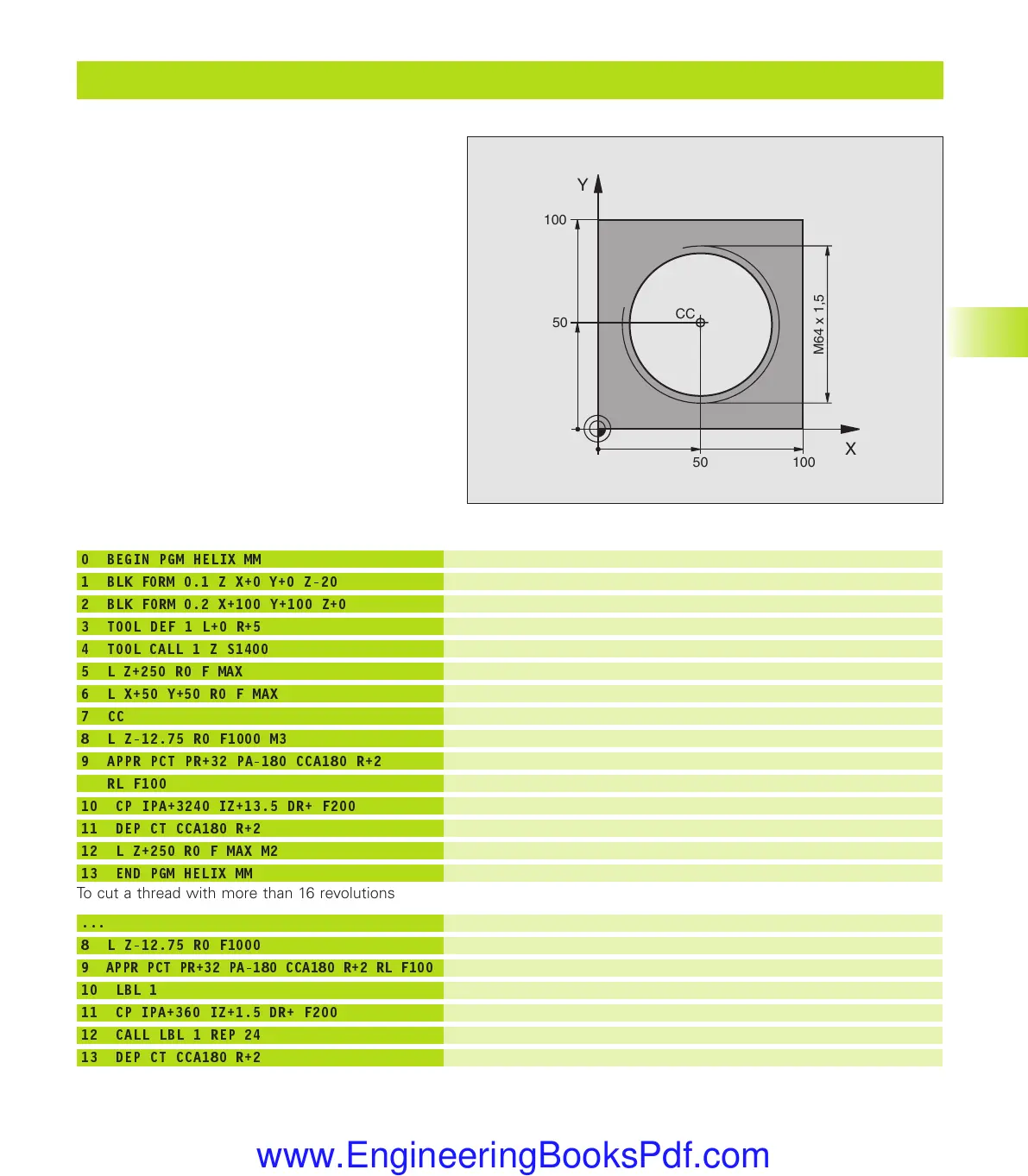

Example: Helix

Define the workpiece blank

Define the tool

tool call

Retract the tool

Pre-position the tool

Transfer the last programmed position as the pole

Move to working depth

Approach the contour on a circular arc with tangential

connection

Helical interpolation

Depart the contour on a circular arc with tangential connection

Retract in the tool axis, end program

Identify beginning of program section repeat

Enter the thread pitch as an incremental IZ dimension

Program the number of repeats (thread revolutions)

0 BEGIN PGM HELIX MM

1 BLK FORM 0.1 Z X+0 Y+0 Z-20

2 BLK FORM 0.2 X+100 Y+100 Z+0

3 TOOL DEF 1 L+0 R+5

4 TOOL CALL 1 Z S1400

5 L Z+250 R0 F MAX

6 L X+50 Y+50 R0 F MAX

7 CC

8 L Z-12.75 R0 F1000 M3

9 APPR PCT PR+32 PA-180 CCA180 R+2

RL F100

10 CP IPA+3240 IZ+13.5 DR+ F200

11 DEP CT CCA180 R+2

12 L Z+250 R0 F MAX M2

13 END PGM HELIX MM

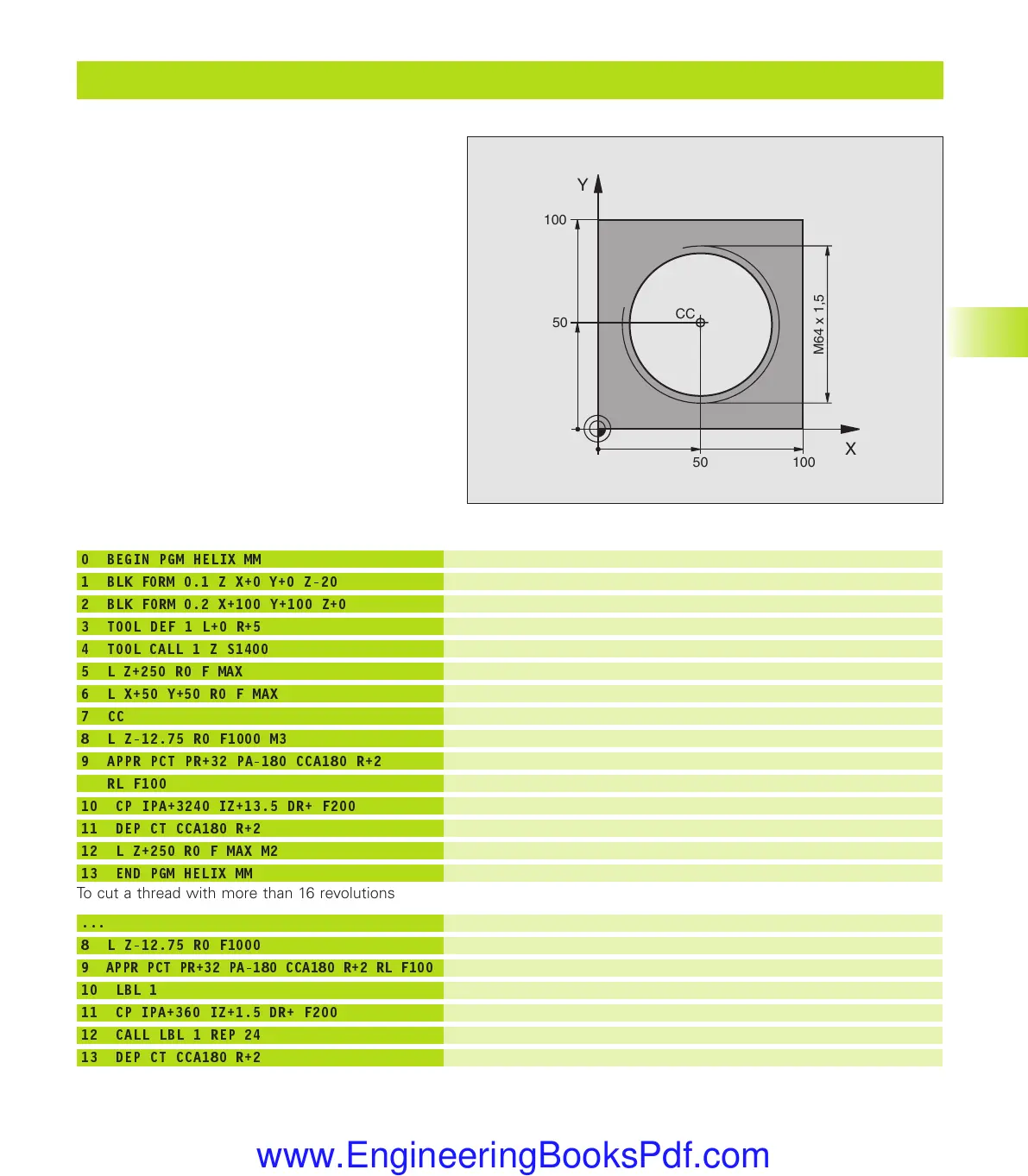

To cut a thread with more than 16 revolutions

...

8 L Z-12.75 R0 F1000

9 APPR PCT PR+32 PA-180 CCA180 R+2 RL F100

10 LBL 1

11 CP IPA+360 IZ+1.5 DR+ F200

12 CALL LBL 1 REP 24

13 DEP CT CCA180 R+2

X

Y

50

50

CC

100

100

M64 x 1,5

Gkap6.pm6 30.06.2006, 07:04117

www.EngineeringBooksPdf.com

Loading...

Loading...