8 Programming: Cycles

176

ú

Workpiece surface coordinate Q203 (absolute value):

Coordinate of the workpiece surface

ú

2nd set-up clearance Q204 (incremental value):

Coordinate in the tool axis at which no collision

between tool and workpiece (clamping devices) can

occur.

ú

Center in 1st axis Q216 (absolute value): Center of the

pocket in the main axis of the working plane

ú

Center in 2nd axis Q217 (absolute value): Center of the

pocket in the secondary axis of the working plane

ú

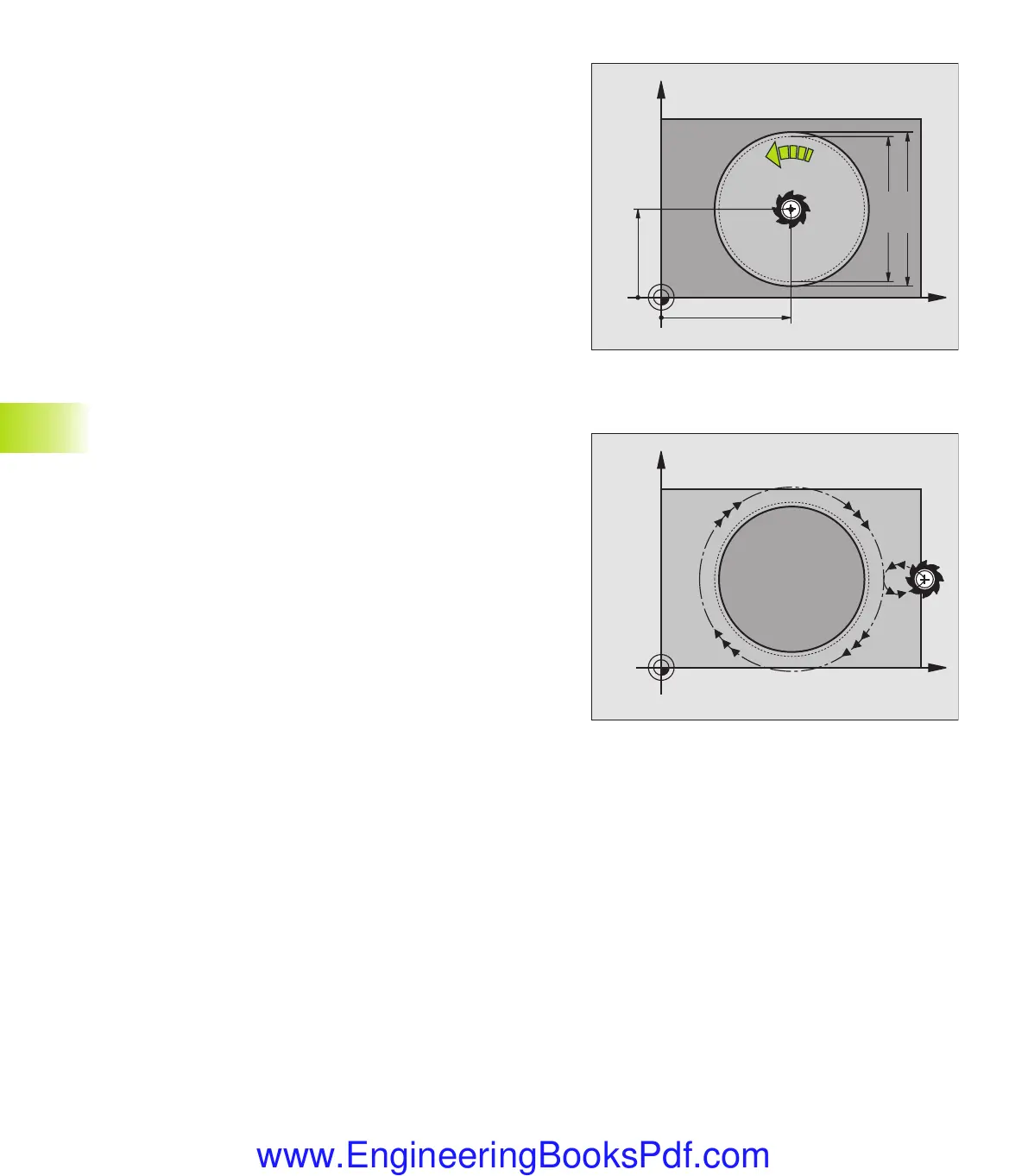

Workpiece blank dia. Q222: Diameter of the

premachined pocket. Enter the workpiece blank

diameter to be less than the diameter of the finished

part.

ú

Finished part dia. Q223: Diameter of the finished

pocket. Enter the diameter of the finished part to be

greater than the workpiece blank diameter.

CIRCULAR STUD FINISHING (Cycle 215)

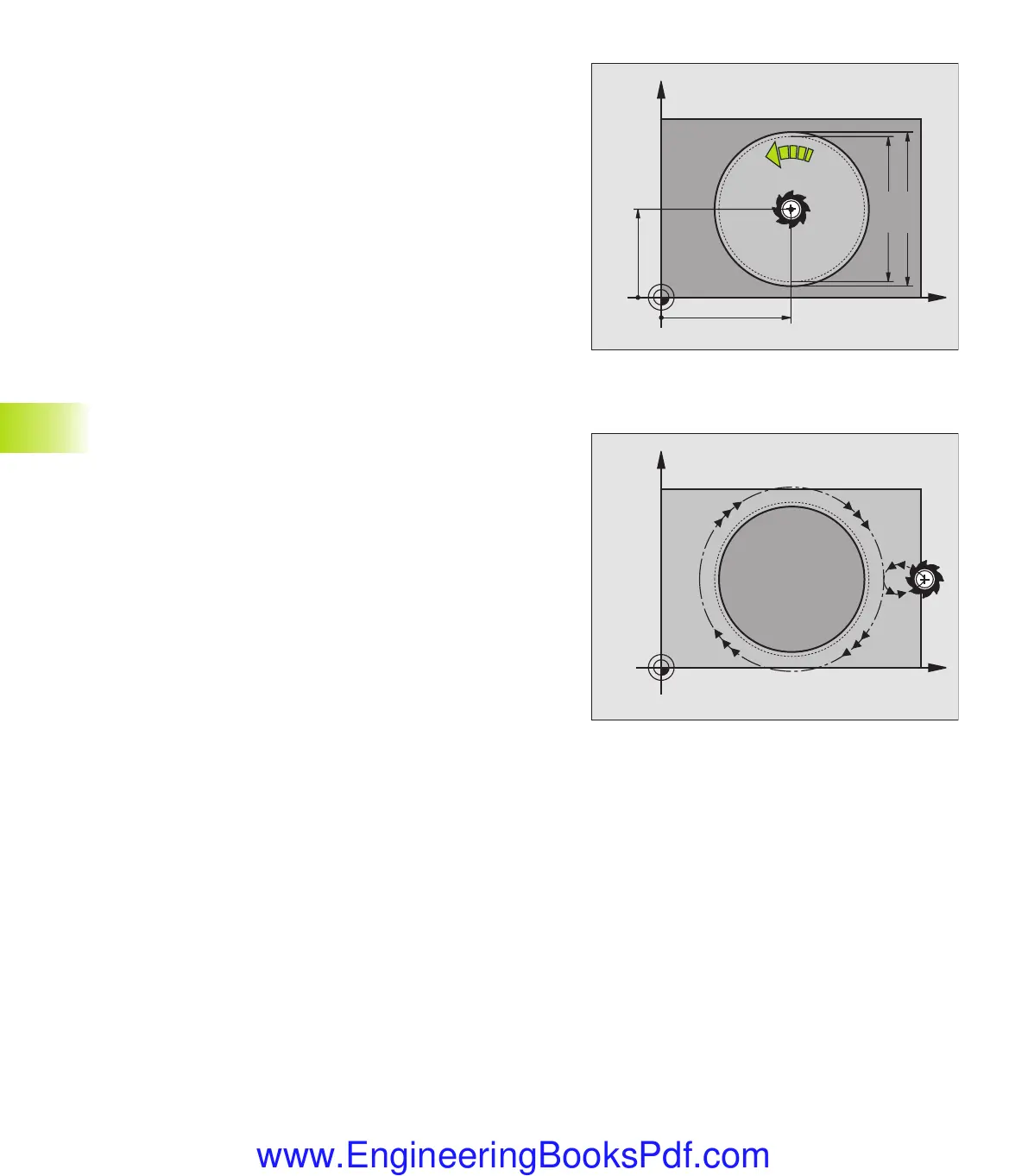

1 The TNC automatically moves the tool in the tool axis to set-up

clearance, or — if programmed - to the 2nd set-up clearance, and

subsequently to the center of the stud.

2 From the stud center, the tool moves in the working plane to the

starting point for machining. The starting point lies to the right of

the stud by a distance approx. 3.5 times the tool radius.

3 If the tool is at the 2nd set-up clearance, it moves in rapid traverse

FMAX to set-up clearance, and from there advances to the first

plunging depth at the feed rate for plunging.

4 The tool then moves tangentially to the contour of the finished

part and, using climb milling, machines one revolution.

5 After this, the tool departs the contour tangentially and returns to

the starting point in the working plane.

6 This process (3 to 5) is repeated until the programmed depth is

reached.

7 At the end of the cycle, the TNC retracts the tool in FMAX to set-

up clearance, or - if programmed - to the 2nd set-up clearance,

and finally to the center of the pocket (end position = starting

position).

X

Y

Q222

Q217

Q216

Q207

Q223

X

Y

8.3 Cycle for Milling Pockets, Studs and Slots

kkap8.pm6 30.06.2006, 07:03176

www.EngineeringBooksPdf.com

Loading...

Loading...