8 Programming: Cycles

172

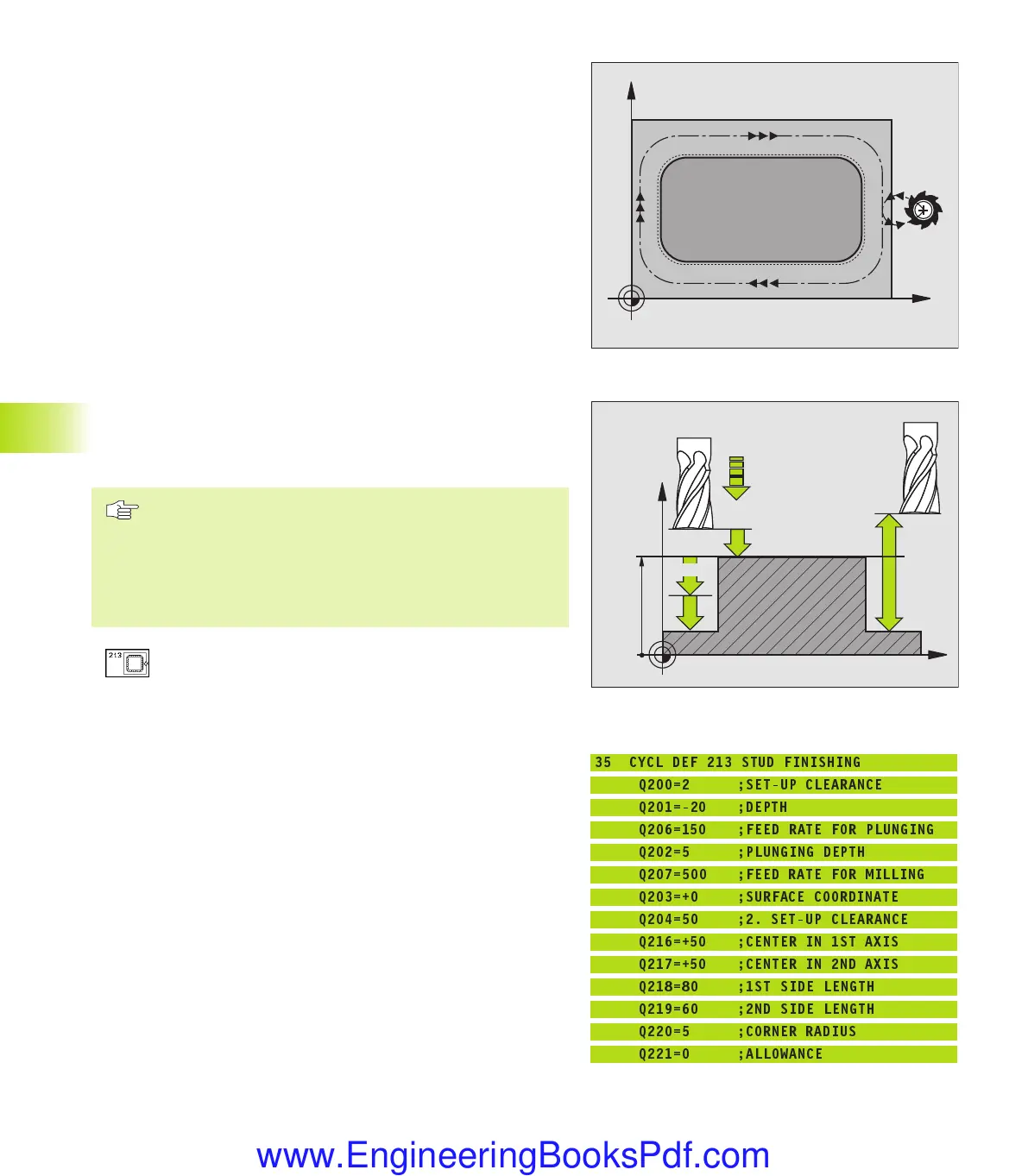

STUD FINISHING (Cycle 213)

1 The TNC moves the tool in the tool axis to set-up clearance, or —

if programmed — to the 2nd set-up clearance, and subsequently

to the center of the stud.

2 From the stud center, the tool moves in the working plane to the

starting point for machining. The starting point lies to the right of

the stud by a distance approx. 3.5 times the tool radius.

3 If the tool is at the 2nd set-up clearance, it moves in rapid traverse

FMAX to set-up clearance, and from there advances to the first

plunging depth at the feed rate for plunging.

4 The tool then moves tangentially to the contour of the finished

part and, using climb milling, machines one revolution.

5 After this, the tool departs the contour tangentially and returns to

the starting point in the working plane.

6 This process (3 to 5) is repeated until the programmed depth is

reached.

7 At the end of the cycle, the TNC retracts the tool in FMAX to set-

up clearance, or — if programmed — to the 2nd set-up clearance,

and finally to the center of the stud (end position = starting

position).

Before programming, note the following:

The algebraic sign for the depth parameter determines

the working direction.

If you want to clear and finish the stud with the same

tool, use a center-cut end mill (ISO 1641) and enter a low

feed rate for plunging.

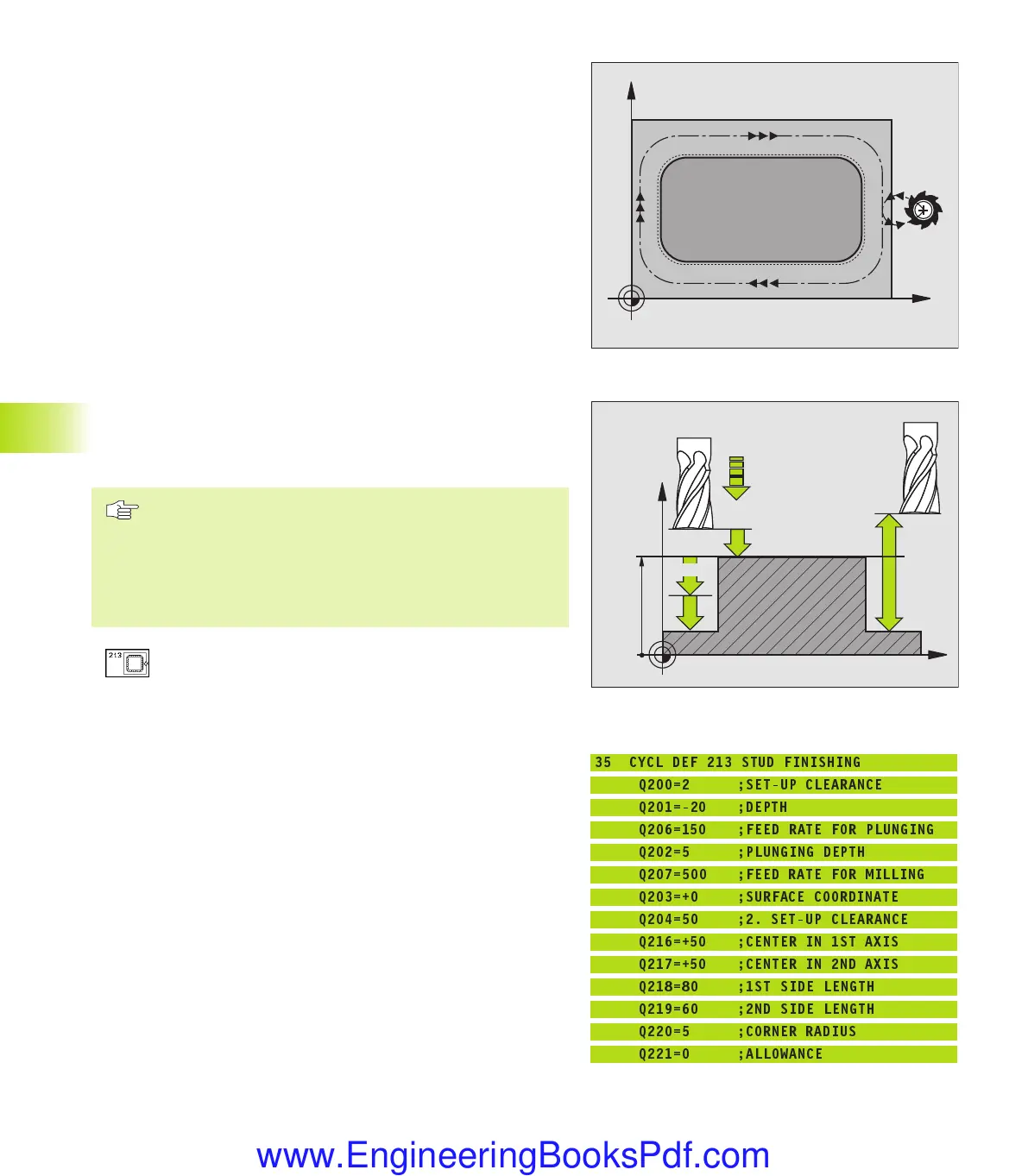

ú Set-up clearance Q200 (incremental value): Distance

between tool tip and workpiece surface.

ú Depth Q201 (incremental value): Distance between

workpiece surface and bottom of stud

ú

Feed rate for plunging Q206: Traversing speed of the

tool in mm/min when moving to depth. If you are

plunge-cutting into the material, enter a low value; if

you have already cleared the stud, enter a higher feed

rate.

ú

Plunging depth Q202 (incremental value):

Infeed per cut Enter a value greater than 0.

ú

Feed rate for milling Q207: Traversing speed of the

tool in mm/min while milling.

ú

Workpiece surface coordinate Q203 (absolute value):

Coordinate of the workpiece surface

X

Y

X

Z

Q200

Q201

Q206

Q203

Q204

Q202

8.3 Cycle for Milling Pockets, Studs and Slots

Example NC blocks:

35 CYCL DEF 213 STUD FINISHING

Q200=2 ;SET-UP CLEARANCE

Q201=-20 ;DEPTH

Q206=150 ;FEED RATE FOR PLUNGING

Q202=5 ;PLUNGING DEPTH

Q207=500 ;FEED RATE FOR MILLING

Q203=+0 ;SURFACE COORDINATE

Q204=50 ;2. SET-UP CLEARANCE

Q216=+50 ;CENTER IN 1ST AXIS

Q217=+50 ;CENTER IN 2ND AXIS

Q218=80 ;1ST SIDE LENGTH

Q219=60 ;2ND SIDE LENGTH

Q220=5 ;CORNER RADIUS

Q221=0 ;ALLOWANCE

kkap8.pm6 30.06.2006, 07:03172

www.EngineeringBooksPdf.com

Loading...

Loading...