103HEIDENHAIN TNC 426 B, TNC 430

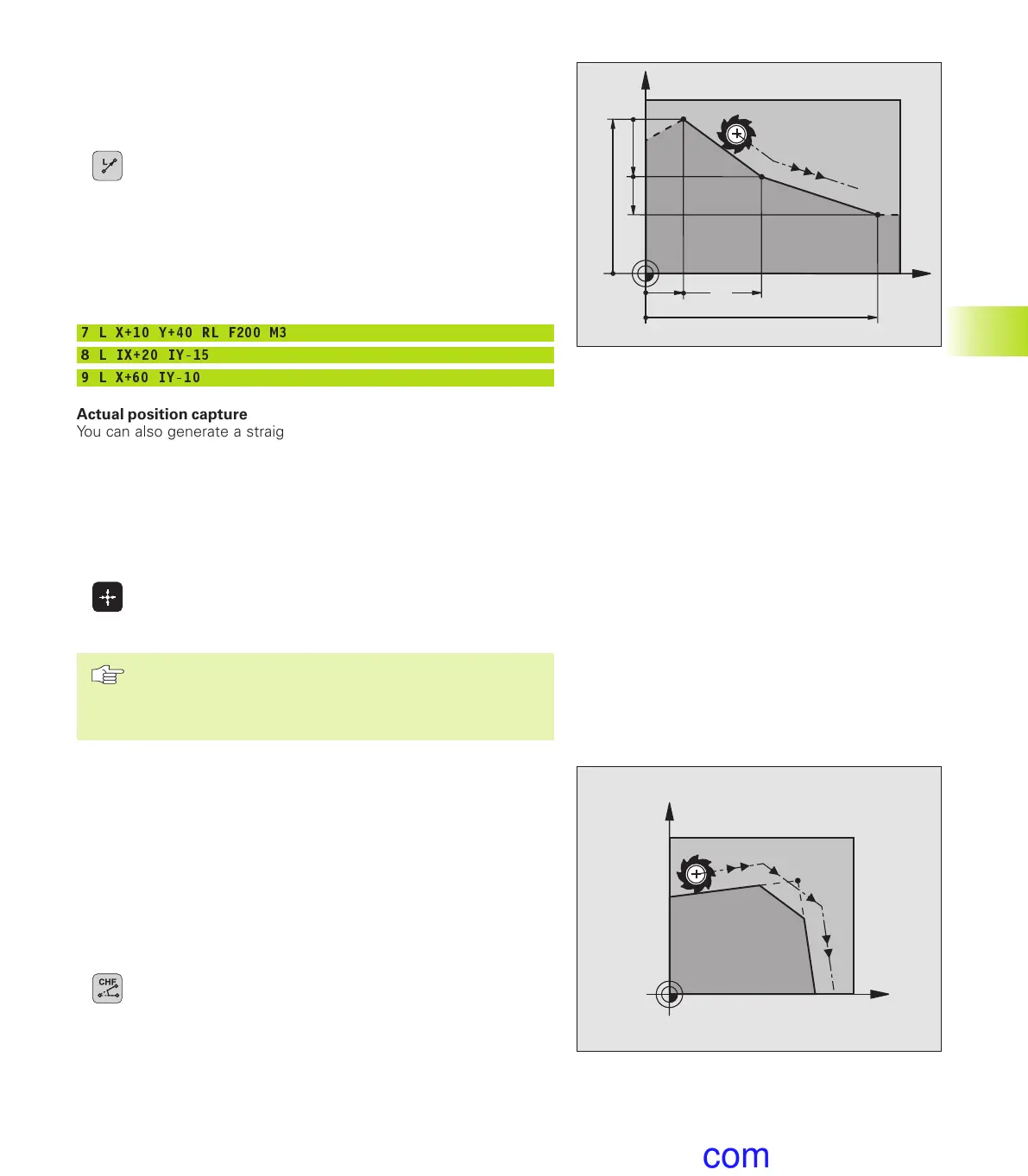

Straight line L

The TNC moves the tool in a straight line from its current position

to the straight-line end point. The starting point is the end point of

the preceding block.

ú Enter the coordinates of the end point for the line.

Further entries, if necessary:

ú

Radius compensation RL/RR/R0

ú

Feed rate F

ú

Miscellaneous function M

Example NC blocks

7 L X+10 Y+40 RL F200 M3

8 L IX+20 IY-15

9 L X+60 IY-10

Actual position capture

You can also generate a straight-line block (L block) by using the

actual-position-capture key:

ú

In the Manual Operation mode, move the tool to the position you

wish to capture.

ú

Switch the screen display to Programming and Editing.

ú

Select the program block after which you want to insert the L

block.

ú Press the actual-position-capture key: The TNC

generates an L block with the actual position

coordinates.

In the MOD function, you define the number of axes that

the TNC saves in an L block (see Chapter 14 ”MOD

Functions,” section ”Selecting the Axes for Generating L

Blocks”).

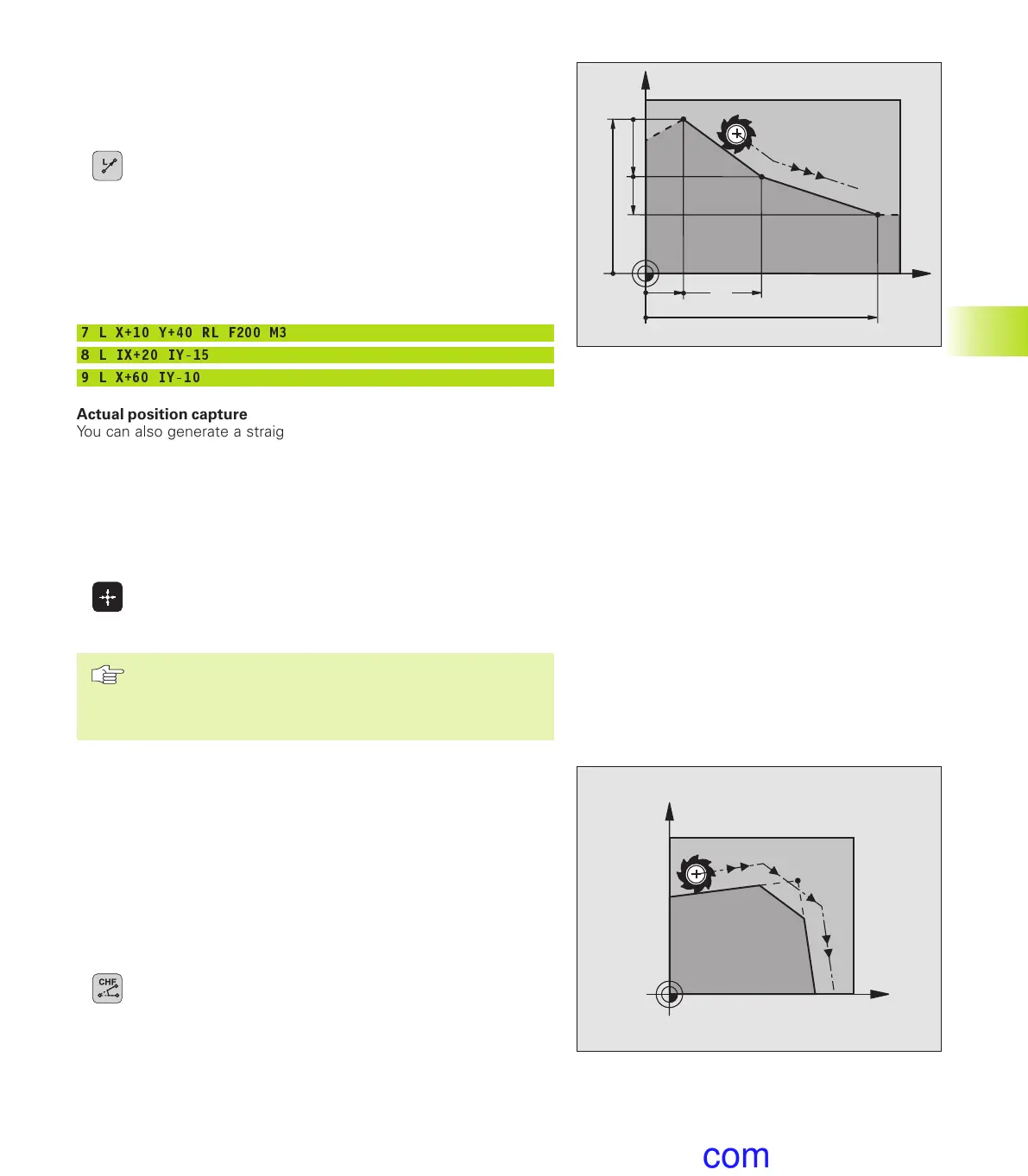

Inserting a chamfer CHF between two straight lines

The chamfer enables you to cut off corners at the intersection of

two straight lines.

■

The blocks before and after the CHF block must be in the same

working plane.

■

The radius compensation before and after the chamfer block must

be the same.

■

An inside chamfer must be large enough to accommodate the

current tool.

ú

Chamfer side length: Enter the length of the chamfer

Further entries, if necessary:

ú Feed rate F (only effective in CHF block)

Please observe the notes on the next page!

X

Y

60

15

40

10

10

20

X

Y

6.4 Path Contours — Cartesian Coordinates

Gkap6.pm6 30.06.2006, 07:04103

www.EngineeringBooksPdf.com

Loading...

Loading...