-127-

Introduction

7.3.2 Periodic Spot Check

The following table lists the spot checks that need to be performed once or twice every 6 or 12 months:

Check Item Check Method Measure

□

Power supply

voltage

Check whether the input AC power of

the system conforms to the product

specications.

Check the power supply reliability.

□

Ambient

temperature and

humidity

Use a thermometer and hygrometer to

check whether the ambient temperature

and humidity conform to the product

specications.

Find out the reasons of ambient

changes and take measures to

ensure that the environment meets

the requirements.

□

Air Check whether corrosive gases exist.

Eliminate the corrosive gas source

and ensure that the environment

meets the requirements.

□

Cleanliness Check whether the machine is clean. Clean the machine.

□

Installation

rmness

Check whether the DIN guide rail and

modules are securely installed.

Ensure that the installation is secure.

□

PLC system

diagnosis log

Check whether new error logs are generated.

For details about troubleshooting

,

see

"7.4 CPU Module LED Display"

.

In addition

,

spot checks need to be performed after device migration

,

renovation

,

and wiring.

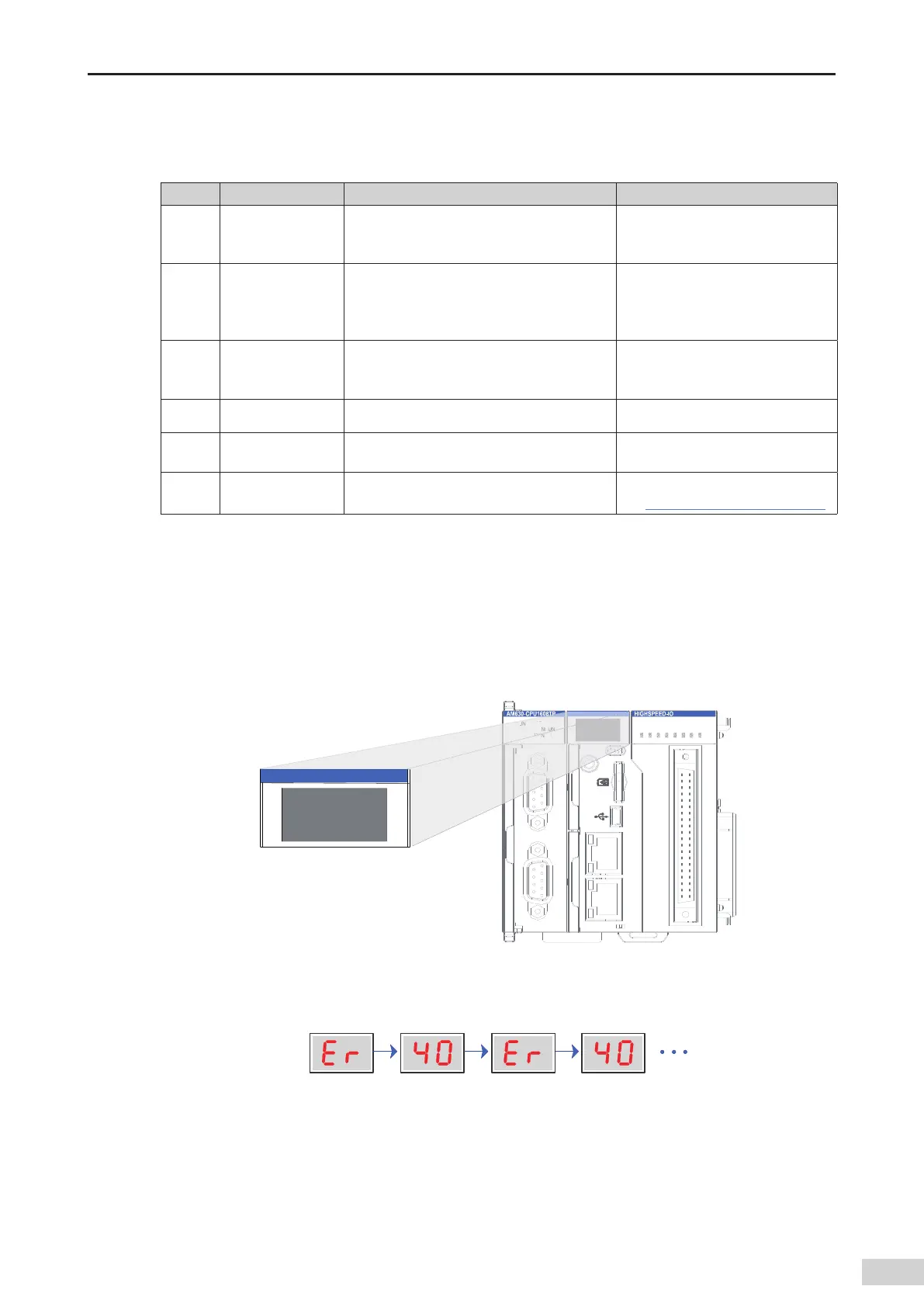

7.4 CPU Module LED Display

7.4.1 Fault Display Mode

When a fault occurs

,

the fault code is displayed on the LED of the CPU module.

MFK

RUN/STOP

3940

21

CN5

CN1 RS 485

CN2 DP/CAN

CN3 Et herNET CN4 Et herCAT

CANERR

CANRUN

BF

SF

ERR

RUN

01 23 7654

27654103

45673210

I

II

LED

"Er" and the fault code are displayed alternately. If the fault code is 40

,

the LED display is as shown in the

following gure:

The fault codes that the LED can display range from 00 to D4 (hexadecimal)

,

which indicate dierent

fault types

,

as listed in the following table:

Loading...

Loading...