-56-

Introduction

4.1 Installation Environment Requirements

4.1.1 Installation Environment

■

Consider operability

,

serviceability

,

environment endurance when installing the PLC on the guide

rail. Do not install the module in the following environment:

■

The ambient temperature is out of the range of -5 ℃ to 55 ℃

.

■

The ambient humidity is out of the range of 5% to 95%.

■

The temperature uctuates dramatically

,

and moisture condensation occurs.

■

Corrosive or combustible gases exist.

■

A large amount of conductive powder such as dust and iron powder

,

oil mist

,

salt

,

or organic solvent

exists.

■

The module is exposed to direct sunlight.

■

Strong electric eld or magnetic eld exists.

■

The machine vibrates or is aected by passed-down impact.

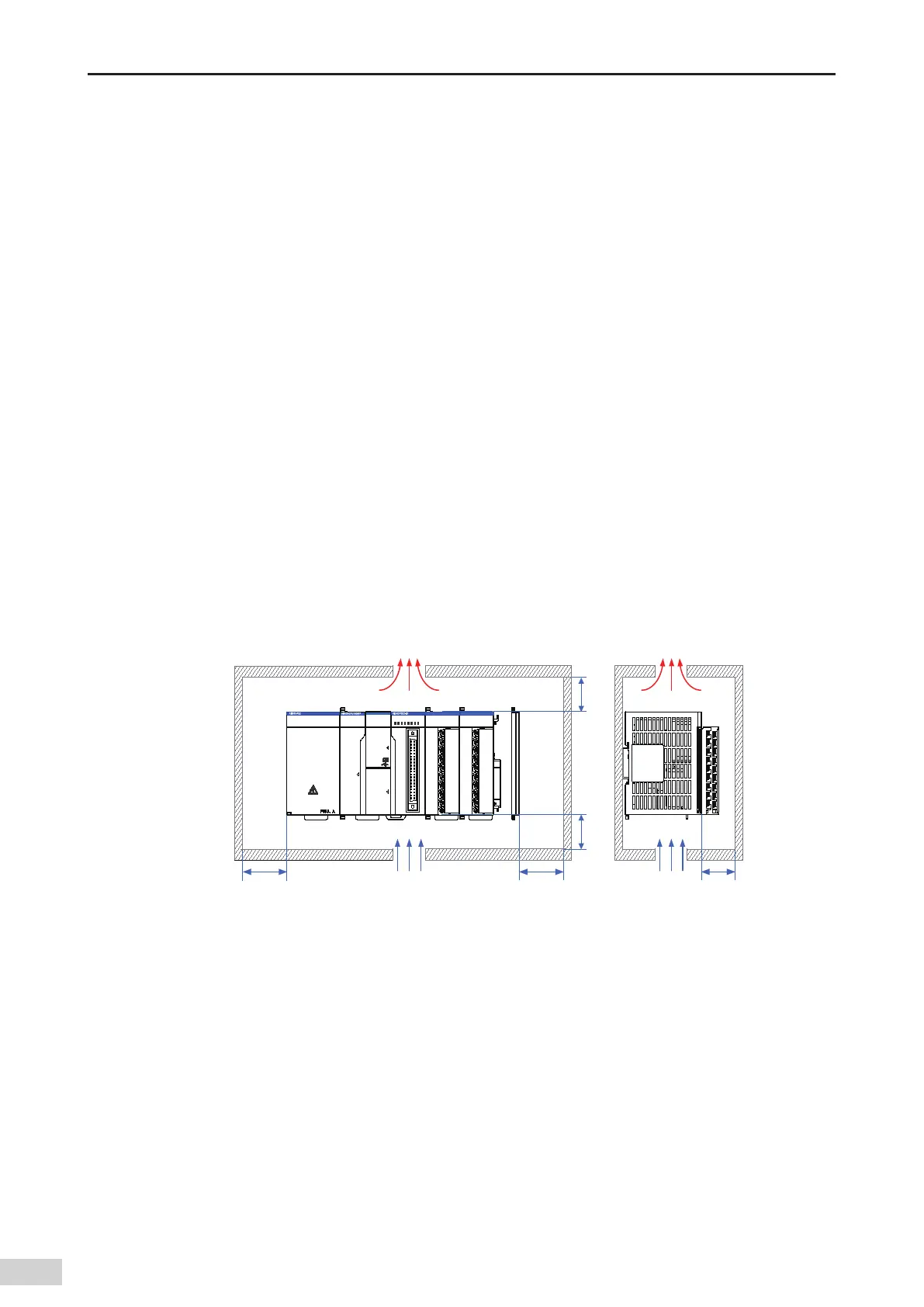

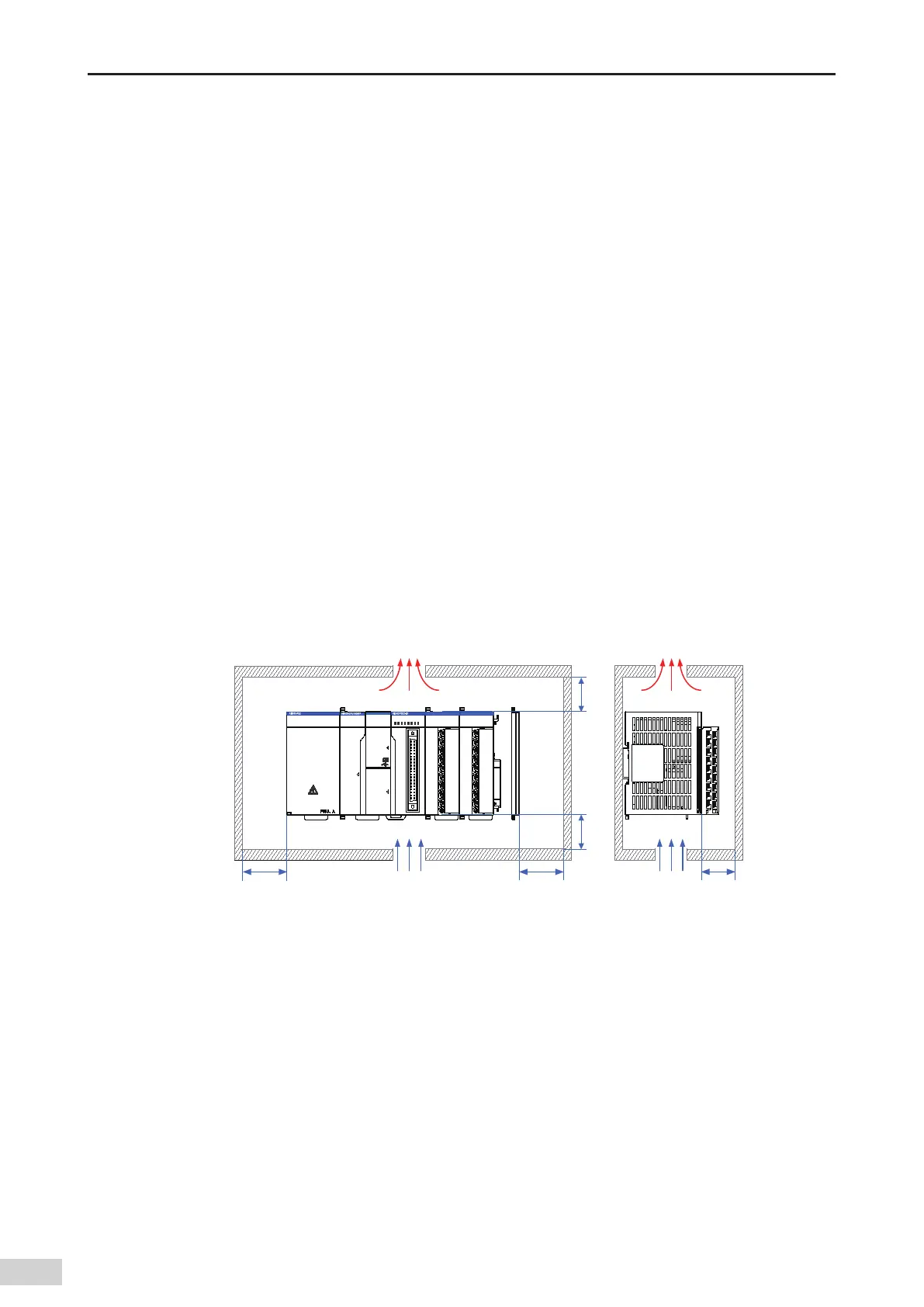

4.1.2 Installation Clearance

To ensure good ventilation and simplify module replacement

,

reserve the clearance specied in the

following gure between the module and walls and components.

DC24V

3940

2 1

CN5

CANERR

CANRUN

BF

SF

ERR

RUN

0 1 2 3 7654

2 765410 3

4 5 6 73210

I

II

RUN/ STOP

MFK

≥

50

mmm

≥ 55 mm

≥ 55 mm

Risk of electric shock

AM600

小心触电

C

N3 Eth

erNET C

N4

Eth

erC

AT

CN1 RS

485

CN2

CAN

≥ 60 mm

≥ 5

0 mm

Figure 4-1 nstallation clearance requirements

4.1.3 Installation Instructions

Comply with the following instructions during installation:

■

Power o the product before installation.

■

Avoid drop-o and impact of the housing

,

terminal block

,

and connector of the module to prevent

damages.

■

Do not disassemble the module.

■

Do not tighten the machine with excessive torque to avoid damaging terminals.

■

After installation and commissioning

,

remove the anti-dust label from the heat dissipation holes on

the top of the module to ensure module reliability when the temperature rises.

Loading...

Loading...