-72-

Introduction

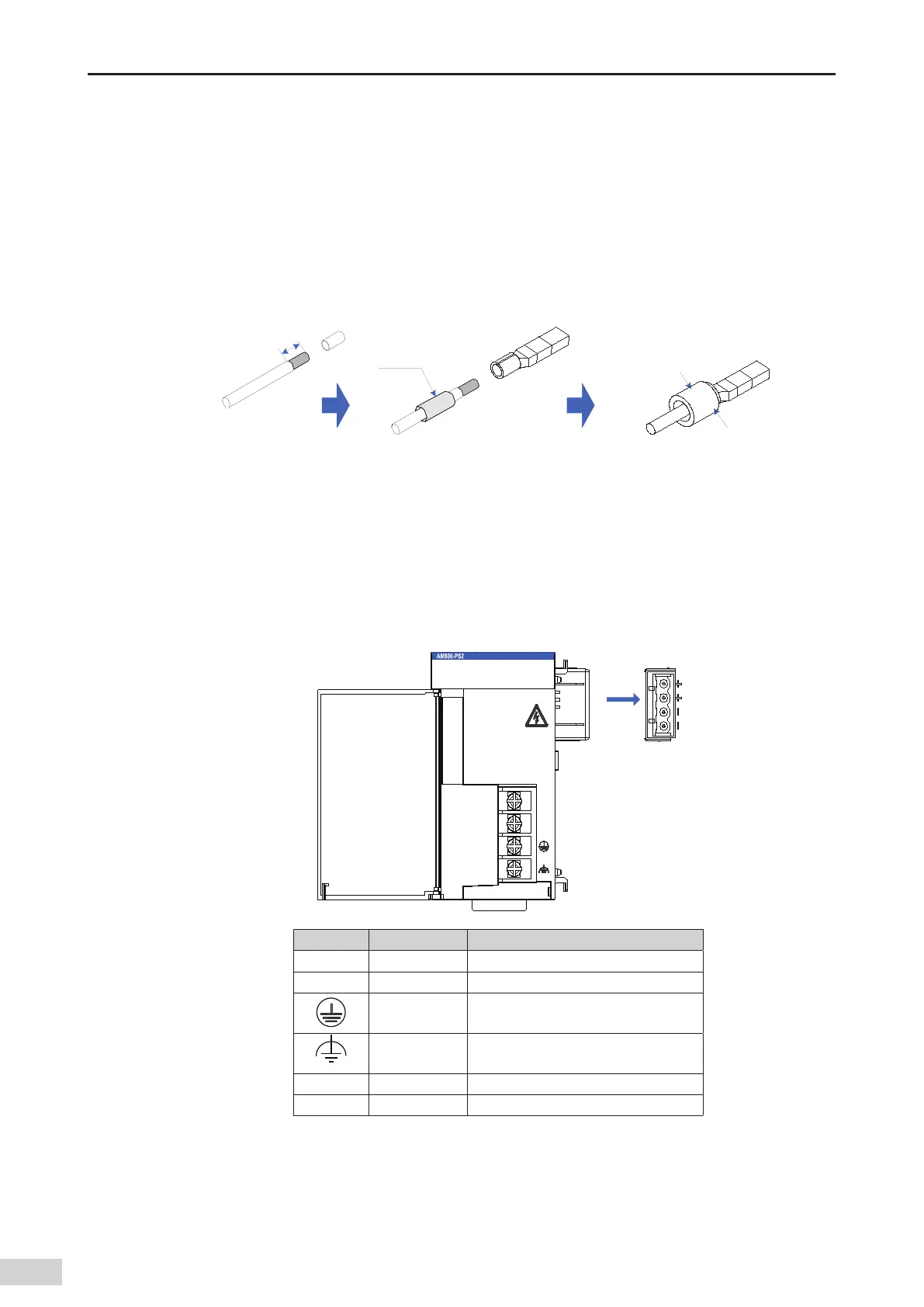

5.2.3 Making Tubular-lug Cables

The procedure for making a tubular cable is as follows:

1) Peel o the insulation coating by 6 mm and pass the cable through a a cable marker sleeve.

2) Insert the exposed end of the cable into the round hole of the lug and use the recommended

crimping plier to crimp the hole.

3) Insert the lug into the terminal block and use a screwdriver to tighten it. The applied torque cannot

exceed 0.45 N·m.

6 mm

Cable marker

sleeve

Crimp with

crimping pliers

Figure 5-9 Making a tubular cable

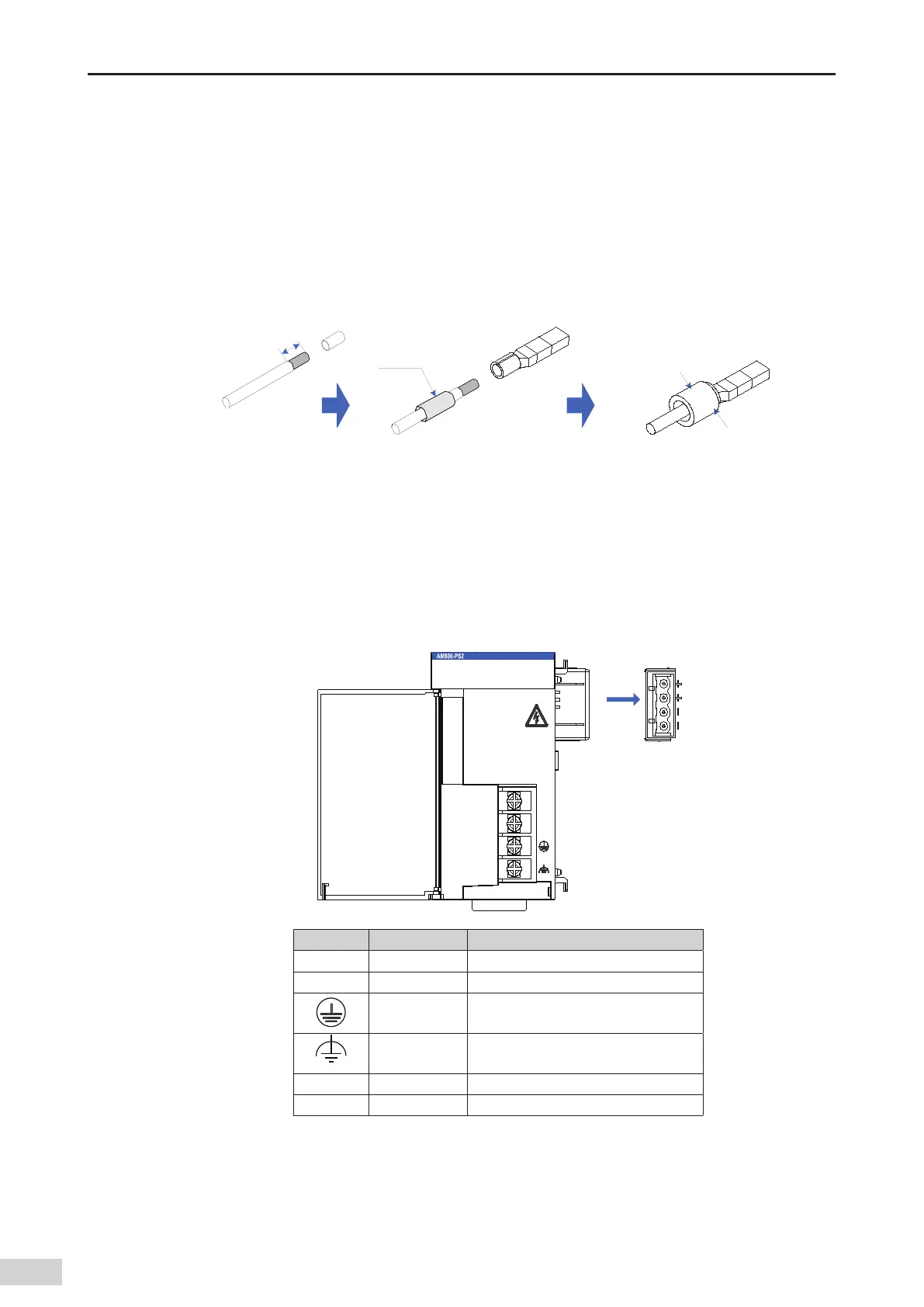

5.3 Wiring of the Power Module

5.3.1 Terminal Denition

The following gure shows the power module AM600-PS2 and the wiring terminal denitions:

L

N

100-240 VAC

INPUT

OUTPUT

24VDC-2A

POWER

Symbol Type Function

L Input AC L input

N Input AC N input

Ground

Protective ground (connected to the

ground wire of the AC input power)

Ground

Function ground (connected to the

system housing)

+24 V Output DC 24 V positive

GND Output DC 24 V ground

Figure 5-10 Wiring terminal denitions of the power module

Loading...

Loading...