– 217 –

1.Sewing machine locked 1-1)Large needle compared with Replace the needle hole guide.

the hole diameter of the needle

hole guide

2.Deformation in sewn patterns 2-1)X timing belt tension is Adjust the X timing belt tension.

maladjusted.

2-2)Y timing belt tension is Adjust the Y timing belt tension.

maladjusted.

2-3)Backlash of the X feed motor Adjust the position of X feed motor.

gear is maladjusted.

2-4)Backlash of the Y feed motor Adjust the position of Y feed motor.

gear is maladjusted.

2-5)The moving torque is strong 5-A)Parallelism of the X-LM guide Adjust the mounting position of the X-LM guide.

in Direction X. is not secured.

5-B)The throat plate auxiliary Adjust the throat plate auxiliary cover height.

cover height is inadequate.

5-C)Inadequate adjustment of the Adjust the feeder bar auxiliary cover rail X.

feeder bar auxiliary cover rail X.

2-6)Traveling torque in X direction 6-A)Parallelism of the Y_LM Adjust the mounting position of the Y-LM guide or Y

or Y direction is excessive. guide or the Y_aux. LM auxiliary LM guide.

guide is not secured.

6-B)There is interference between Adjust the throat plate auxiliary cover height.

the throat plate auxiliary cover

and the throat plate.

6-C)Inadequate adjustment of the Adjust the feeder bar auxiliary cover rail Y.

feeder bar auxiliary cover rail Y.

2-7)Pressing pressure is too low. 7-A)Inadequate adjustment of the Adjust the pressure switch.

pressure switch

7-B)Regulator is maladjusted. Adjust the regulator.

7-C)Supply air pressure is too low.Adjust the supply air pressure.

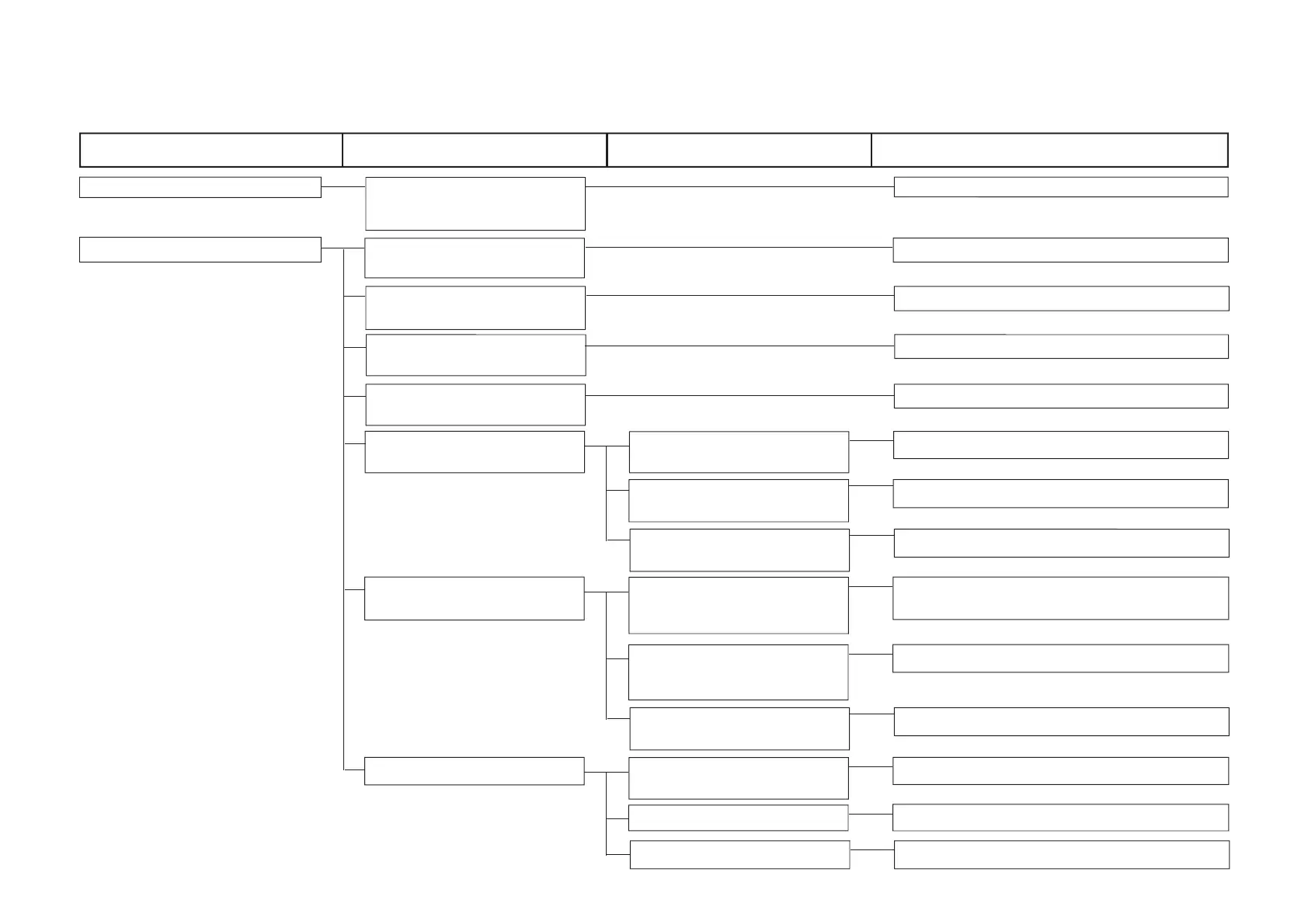

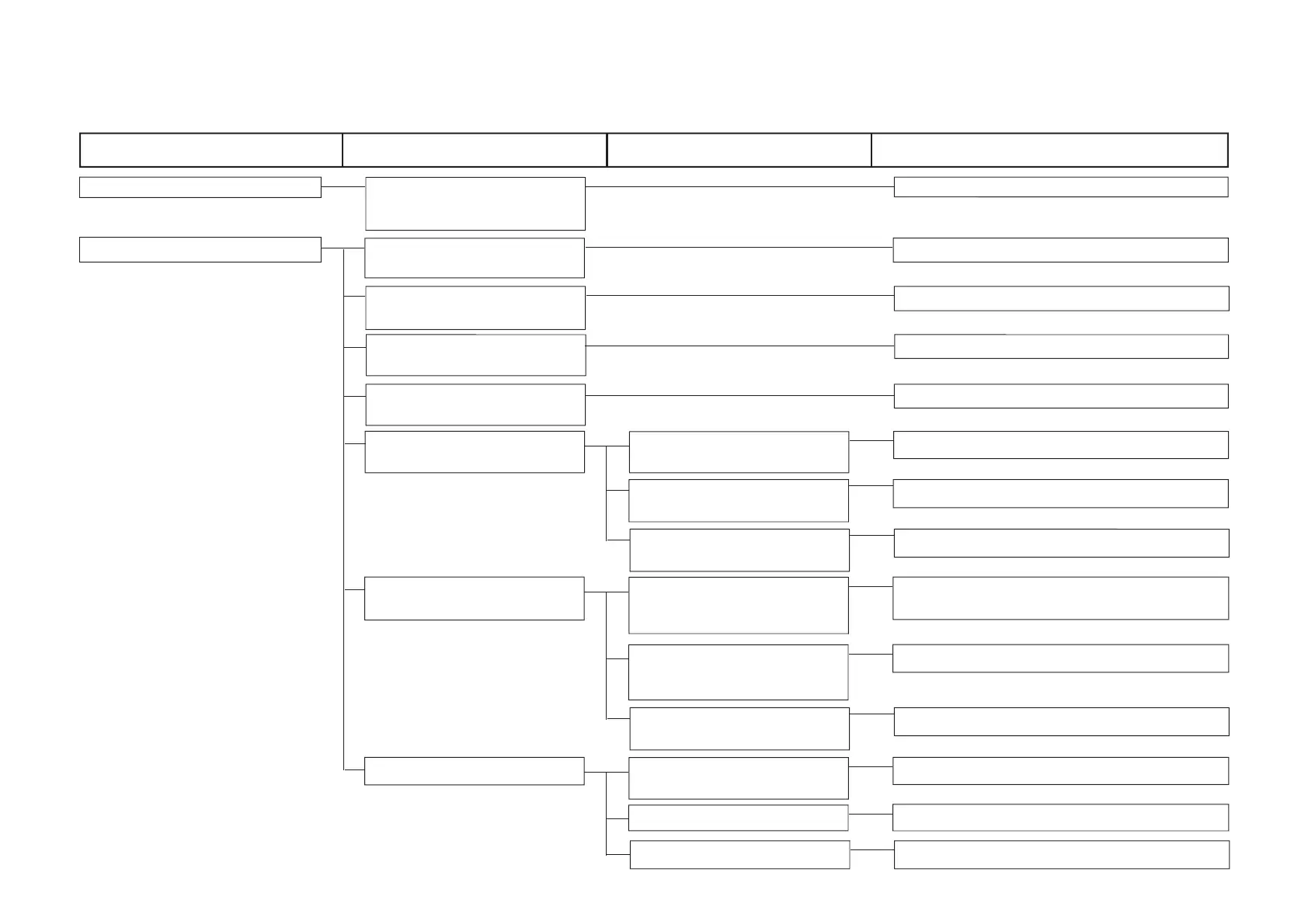

Trouble Cause (1) Cause (2) Check and corrective measures

13. Troubles and corrective measures

(1) Mechanical parts

Loading...

Loading...