MAINTENANCE

WB140-2N, WB150-2N 3-27

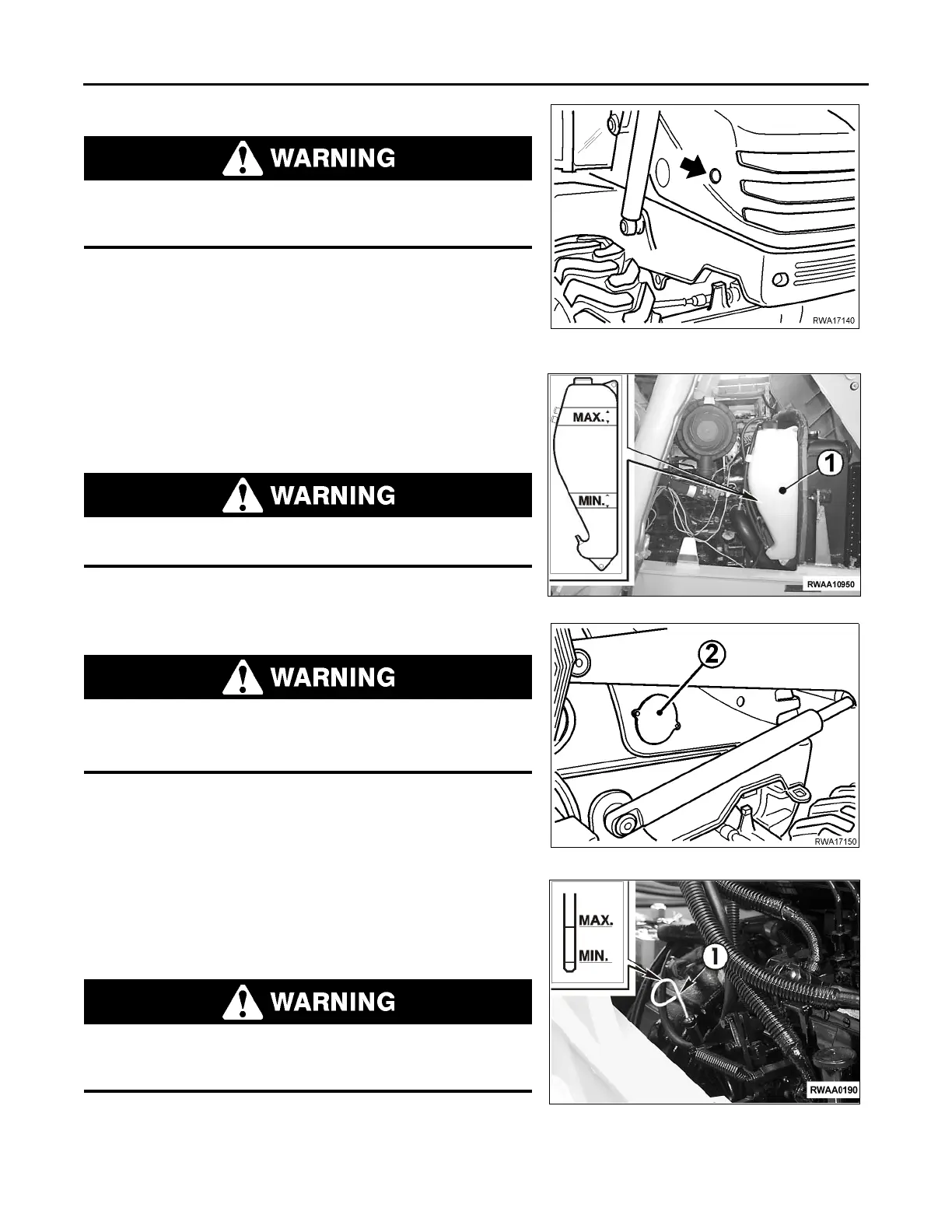

CHECKING COOLANT LEVEL

The coolant level can be checked in expansion tank (1) with the engine

cold, coolant must be between the MIN. and MAX. lower marks.

The check must be performed through the hole positioned on the right

side of the engine hood and the coolant level must be above the MIN.

lower mark.

If the level is near the lower limit of the MIN. mark, fill the tank with

coolant, and if the level decreases considerably and constantly, check

the radiator, engine, and radiator body for leaks. Also check fluid level

in the radiator. See “CHECKING COOLANT LEVEL” on page 3-27.

Expansion tank (1) can be reached after opening the engine hood.

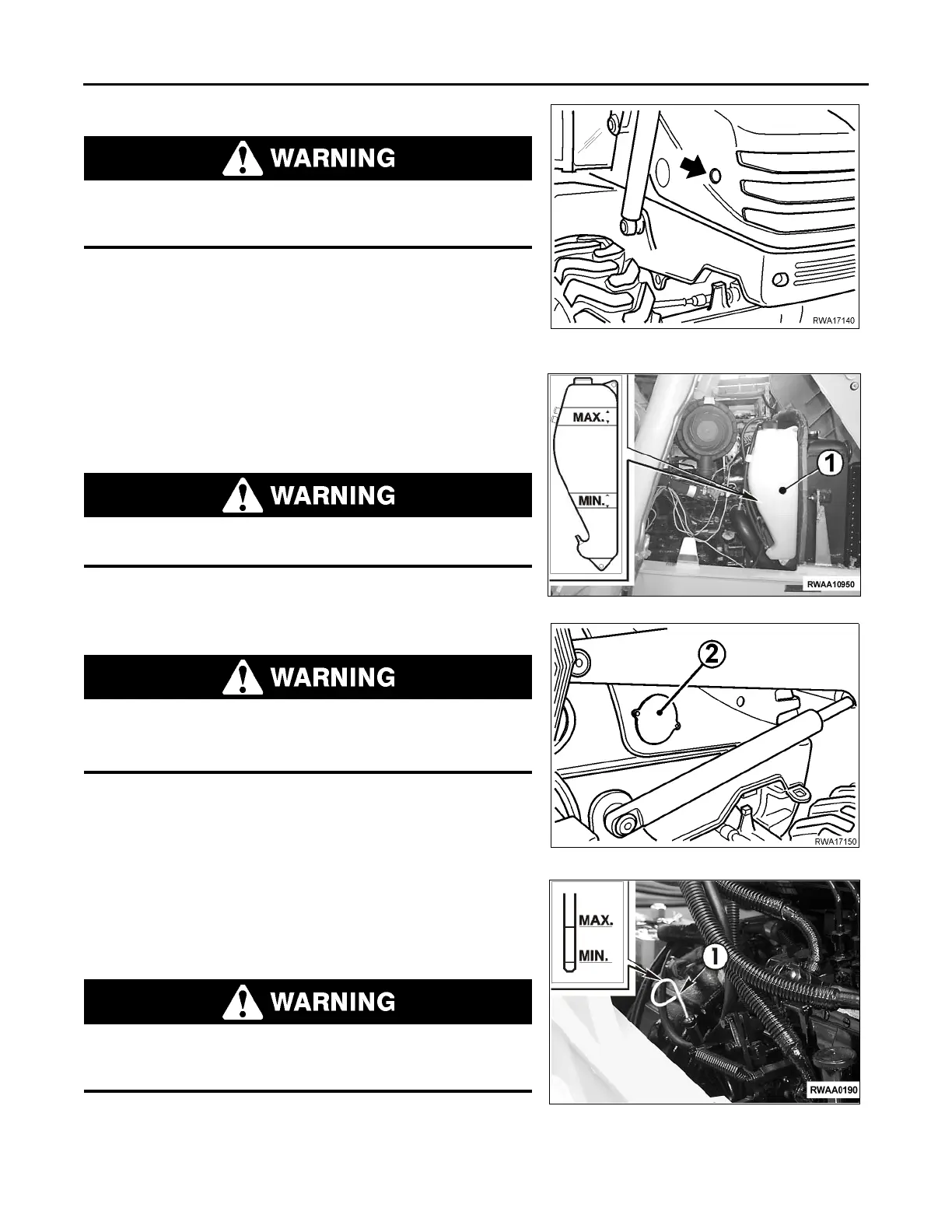

CHECKING ENGINE OIL LEVEL

Dipstick (1) can be reached through opening in the right side of engine

hood, which is protected by inspection cover (2).

The check must be performed with cold engine and the machine located

on level ground.

Oil level can be checked on the graduated dipstick (1) and must be

between MIN. and MAX. marks. If the level is near the MIN. mark, top

off with oil suitable for the ambient temperature, as prescribed in the

lubricant chart. See “FUEL, COOLANT, AND LUBRICANTS” on

page 3-7.

• Do not remove the radiator cap; the coolant must be

checked with the engine cold, through the expansion

tank.

• The upper MIN. and MAX. marks indicate the expansion

level of the coolant at operating temperature.

• After the machine is stopped, the engine is very hot.

• Let the engine cool down before performing any check.

• Hot engines may cause burns.

• If it is necessary to check the oil level during or soon

after work, stop engine and wait for 15 minutes before

checking.

Loading...

Loading...