MAINTENANCE

WB140-2N, WB150-2N 3-39

CHECKING HYDRAULIC TRANSMISSION

OIL LEVEL

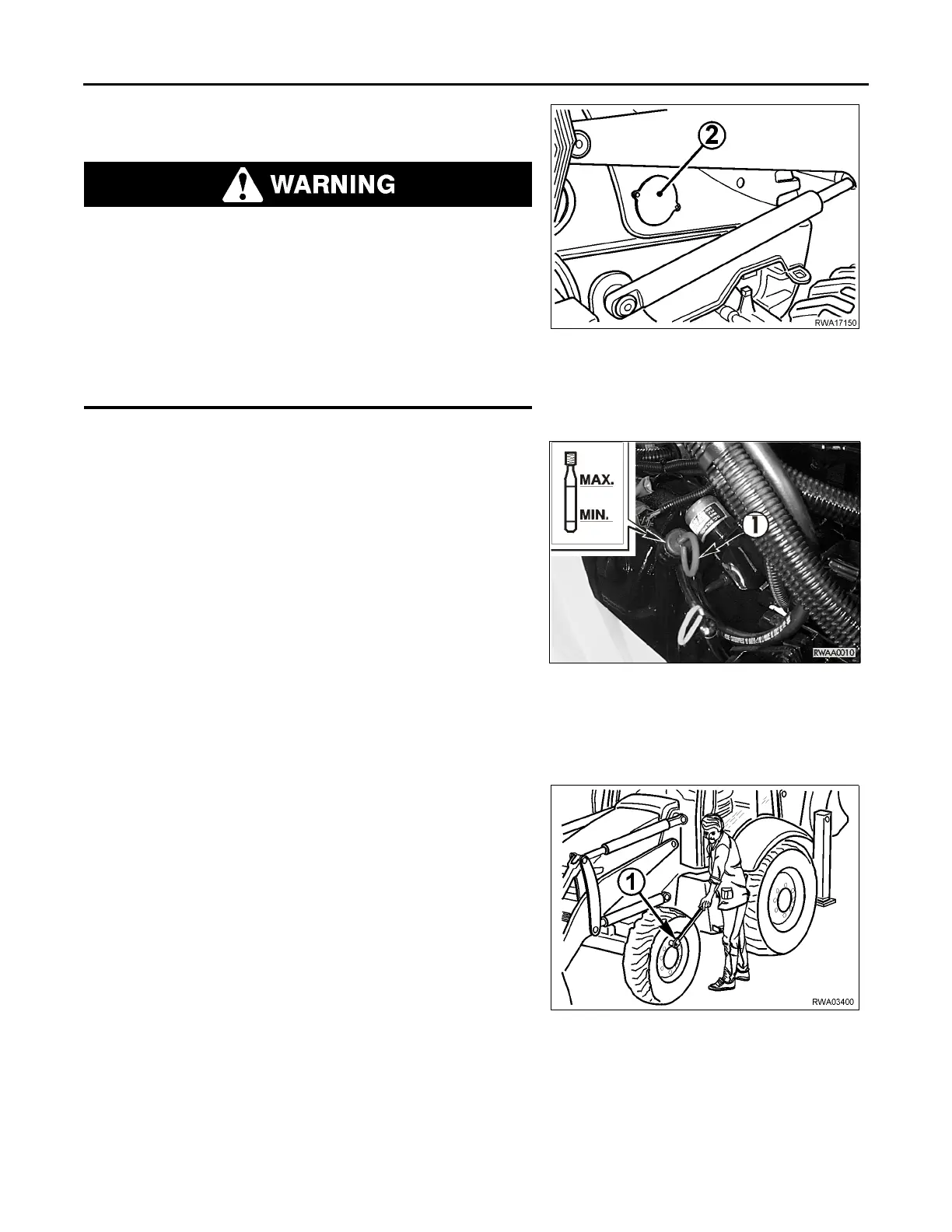

Dipstick (1) can be reached through the opening on the right side of the

engine hood, which is protected by inspection cover (2).

The level must be checked with the engine running at 800 - 1000 rpm

and with the transmission oil at operating temperature.

The oil must always reach the maximum level mark, or be very near it.

To add oil, use the dipstick (1) filler tube and the prescribed oil. (See

“FUEL, COOLANT, AND LUBRICANTS” on page 3-7).

★ After checking the oil level, close inspection cover (2) and lock it.

CHECKING WHEEL LUG NUT TORQUE

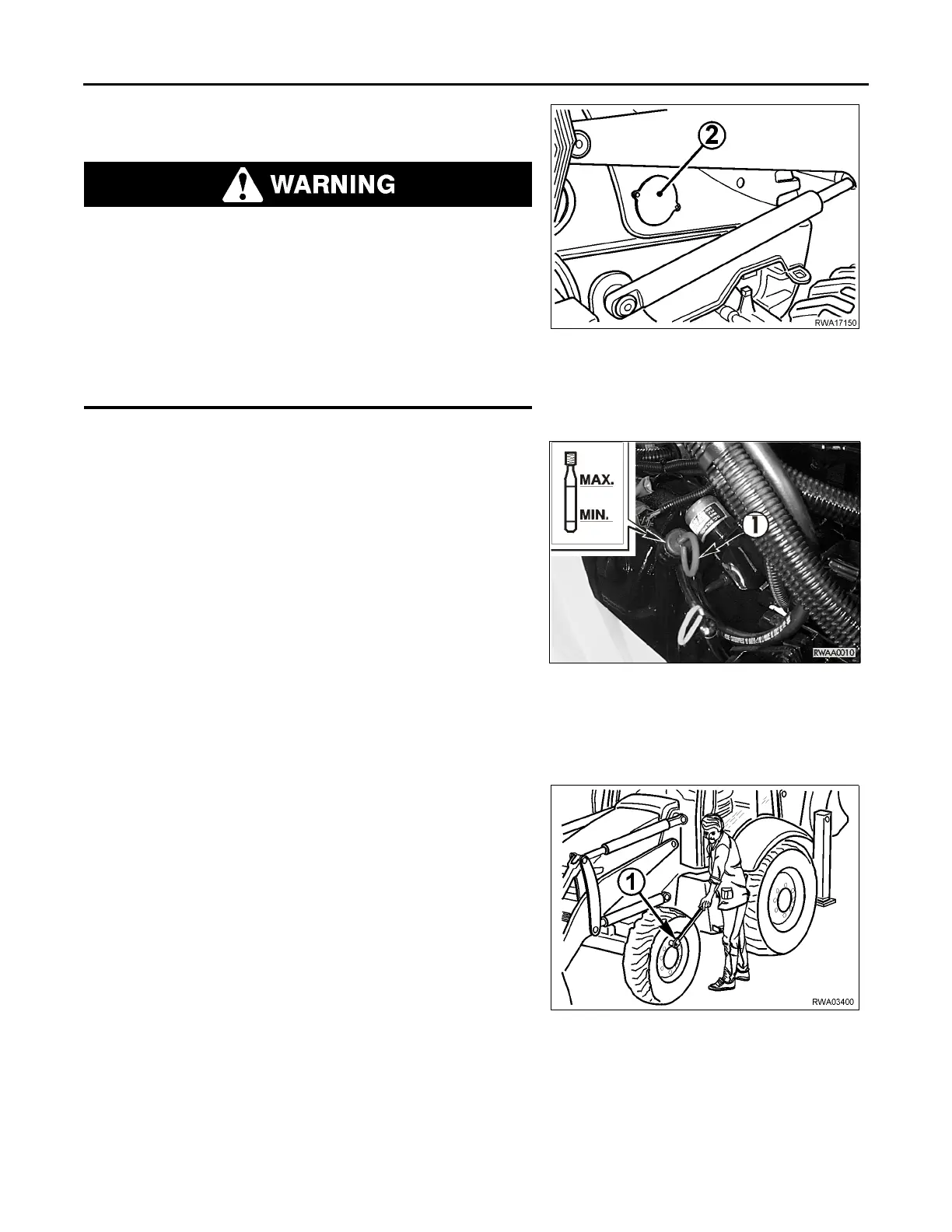

This check is used to verify that driving torque of the wheel lug nuts on

the hubs are correct.

The driving torque must be checked by means of a torque wrench (1) set

according to the values indicated in paragraph See “SPECIFIC TIGHT-

ENING TORQUES” on page 3-21.

(Use a 27 mm wrench for the front wheels).

(Use a 32 mm wrench for the rear wheels).

★ Do not Increase the specified driving torque and keep it within the

prescribed ranges.

★ When the driving torque must be checked, do not lubricate the

thread.

• Level must be checked with the engine running and

transmission oil at operating temperature; be very care-

ful, in order to avoid burns.

• If it is necessary to add oil, stop engine before opening

the engine hood. Prevent possible injury from unex-

pected machine movement. Never rely on directional

control lever alone to keep machine from moving. It can

unexpectedly roll or move under power, resulting in

death or serious injury. Always engage park brake to

hold the machine.

Loading...

Loading...