MAINTENANCE

WB140-2N, WB150-2N 3-51

MAINTENANCE EVERY 2000 HOURS

OF OPERATION

• Perform these operations together with those to be initiated every

50, 250, 500, and 1000 HOURS.

CHANGING HYDRAULIC SYSTEM OIL AND

CLEANING SUCTION FILTER

★ On machines containing synthetic biodegradable hydraulic oil type

HEES, replace oil after the first 500 hours of operation and succes-

sively every 2000 hours, or at least once a year.

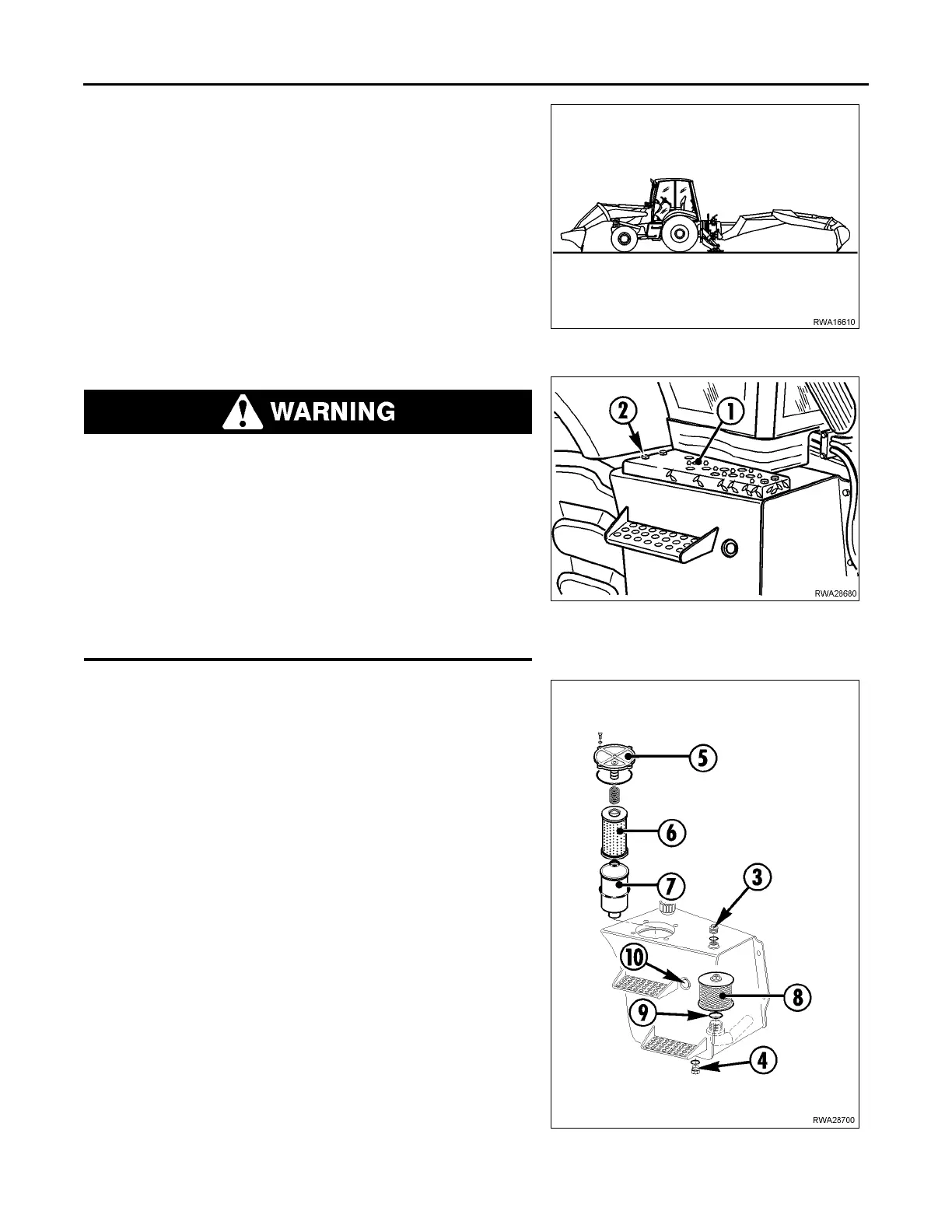

The filter can be reached after removing fastening screws (2) and plat-

form (1), using a 17 mm wrench.

1. Remove filler cap (3), using a 24 mm wrench.

2. Remove drain plug (4) and let the oil flow out. Collect it in a con-

tainer with suitable capacity, using a 41 mm wrench.

3. Remove upper flange (5), filter cartridge (6), and filter casing (7),

using a 13 mm wrench.

4. Remove strainer filter (8), complete with gasket (9) and clean it

with light solvents (petrol, kerosene, diesel oil, etc.).

★ Carefully check the filter element and if it is not in perfect con-

dition, replace it.

5. Reinstall filter (8) complete with gasket (9).

6. Replace filter cartridge (6) and reassemble the whole unit. (See

“CHANGING HYDRAULIC SYSTEM OIL FILTER” on page 3-

43).

7. Reinstall drain plug (4) and fill oil tank with the prescribed oil until

it reaches the proper level at (10).

• After stopping engine, with the machine positioned so

that maintenance can be performed (see fig.), release

residual pressures from the work equipment system (by

operating the controls more than once) and from the

tank (by slowly loosening the filler cap).

• Let the oil cool down until it reaches 40-45°C (104-113°F)

before performing any maintenance.

• Immediately clean any area dirty with oil.

• Oils, filters, coolant, and the battery are considered spe-

cial waste and must be collected and disposed of

according to all anti-pollution regulations in force.

Loading...

Loading...