MAINTENANCE

WB140-2N, WB150-2N 3-47

MAINTENANCE EVERY 1000 HOURS

• Perform these operations together with those initiated every 50, 250,

and 500 HOURS

CHANGING FRONT AXLE OIL.

Perform this operation with the machine positioned on level ground and

at operating temperature, so that the oil becomes fluid and can be easily

drained, which facilitates the elimination of any suspended solid

particles.

DIFFERENTIAL

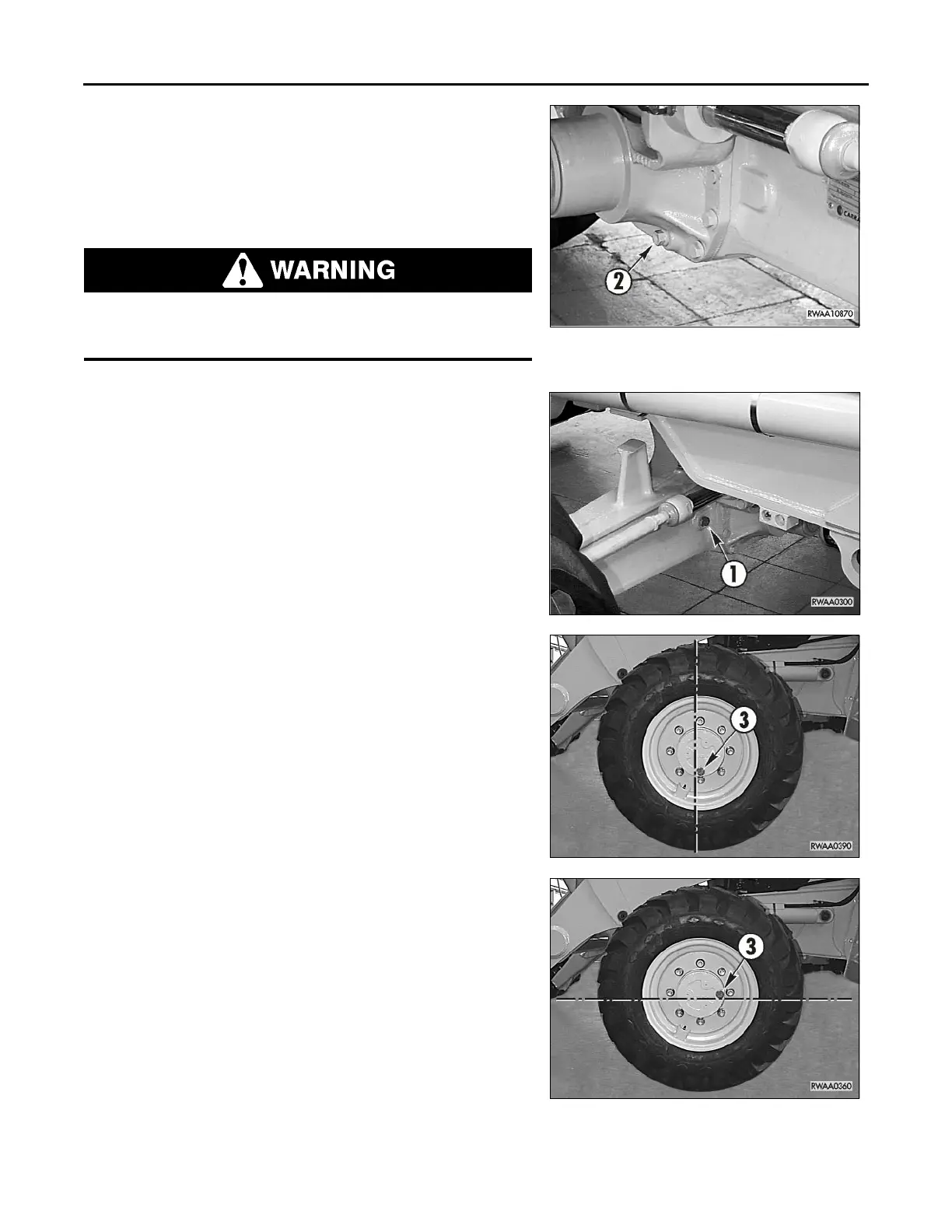

1. Remove drain plug (2) and let the oil flow out completely. Collect it

in a container with suitable capacity. While the oil flows out,

remove plug (1). Use a 17 mm wrench.

2. Once the oil has been drained, reinstall plug (2) and pour oil of the

prescribed type through hole (1), until the level corresponding to

the lower edge of the hole itself is reached.

3. Reinstall plug (1).

PLANETARY

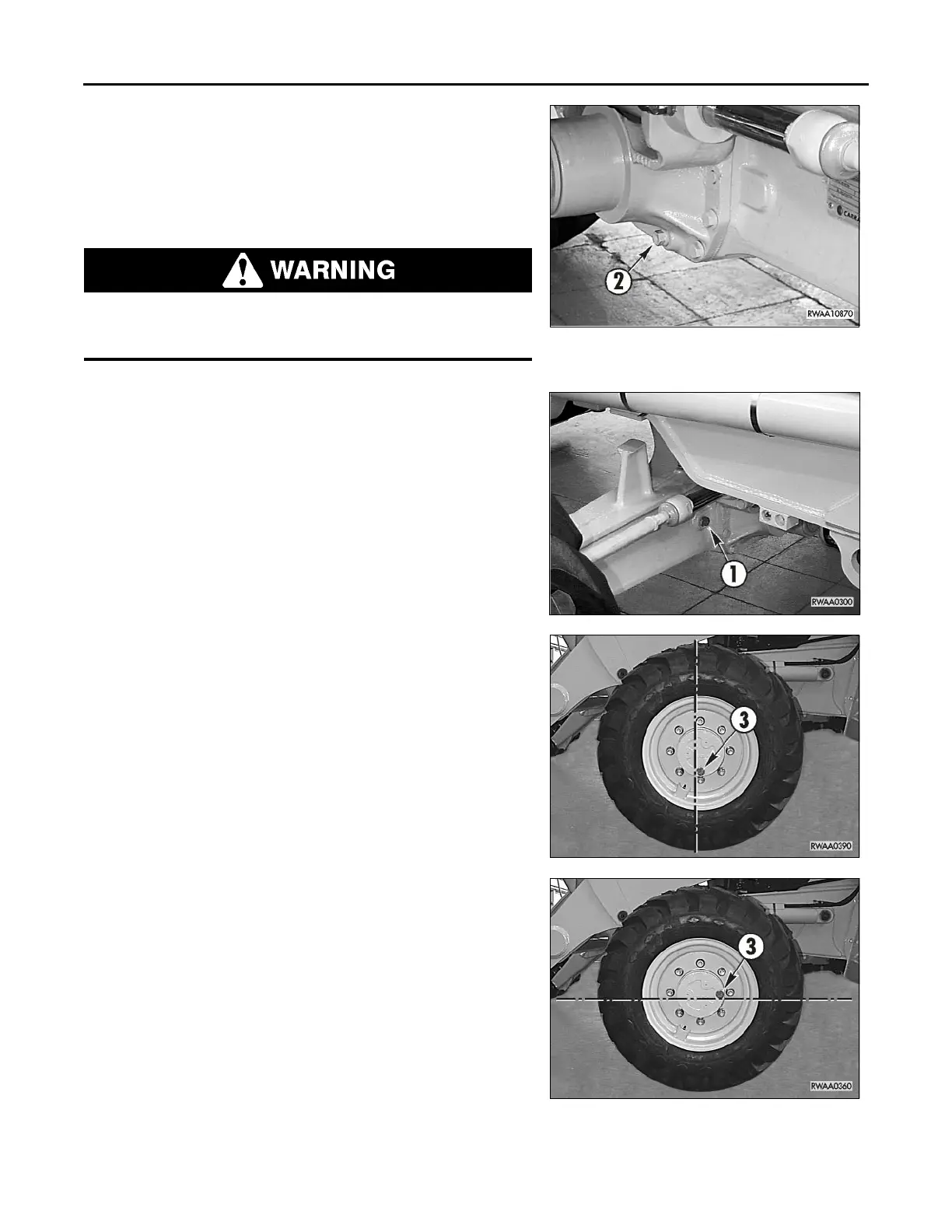

1. Move the machine until plug (3) is in a low position on the vertical

axis.

2. Remove plug (3) and let the oil flow out, Collect it into a container

with suitable capacity, using a 17 mm wrench.

3. Once oil has been drained, move the machine until plug (3), which

serves also as level indicator, is positioned on the horizontal axis.

4. Pour oil of the prescribed type through the hole until the lower edge

of the hole itself is reached.

5. Reinstall plug (3).

★ Move the machine both forward and backward. Stop it to check the

oil level again.

★ Always use oil of the prescribed type. (See “FUEL, COOLANT,

AND LUBRICANTS” on page 3-7).

• Oils, filters, coolant, and the battery are considered spe-

cial waste and must be collected and disposed of

according to all anti-pollution regulations in force.

Loading...

Loading...