Maintenance work on the superstructure

8.8 Main boom

8 - 66 3 302 756 en Maintenance manual

GMK6400

16.11.2018

8.8.2 Lubricating the telescopic sections

Grease, spare

parts, tools

– A grease gun for the grease nipples on the locking pins.

– A grease gun for the grease nipples on the upper telescopic slide faces.

– A brush or roller for the outer, upper and lower telescopic slide faces.

H

Manitowoc Crane Group Germany GmbH recommends using pneumatic

grease spray guns for more effective lubrication of the telescopic slide

faces:

Prerequisites – The truck crane must be level.

– The Mega-Wing-Lift (MWL) must be removed; à Lattice extension

operating manual

.

– The hook block must be unreeved.

– The main boom must be completely retracted and lowered into horizontal

position.

– A rigging mode must have been set up using the telescope positions

required for maintenance as specified in the lifting capacity table;

à Lifting capacity table.

– The RCL code for the current rigging mode must be entered.

H

If at the start you set up a rigging mode under which the telescope posi-

tions 44/100/0/0 are released in the context of the corresponding lifting ca-

pacity table, this rigging mode allows you to perform the complete main-

tenance work on the main boom.

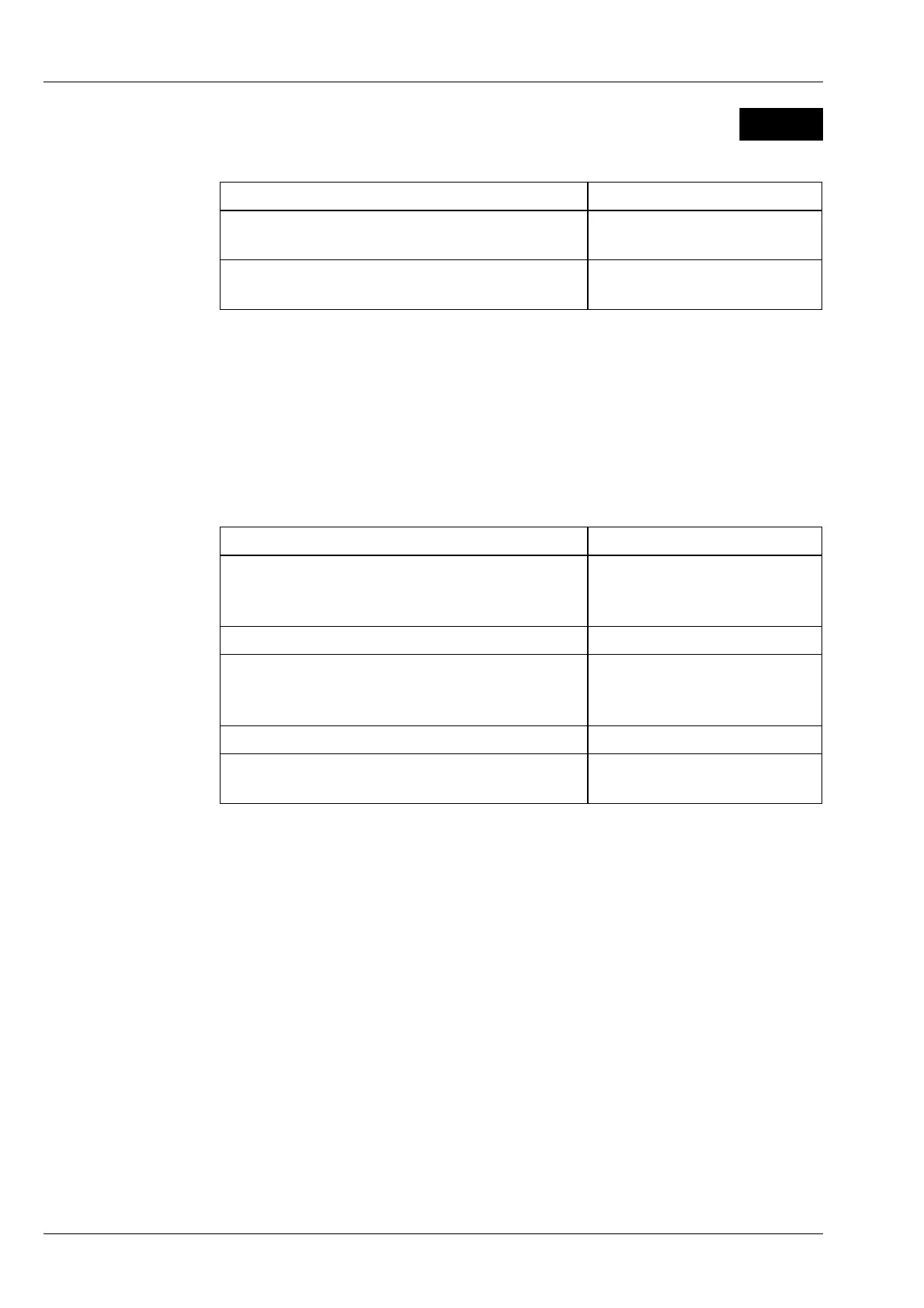

Designation GROVE part no.

Lubricant for the locking pins:

RHUS 2 AF, 1 kg can

03325215

Slide paste for the telescopic slide faces:

PAL1, 25 kg bucket

02314698

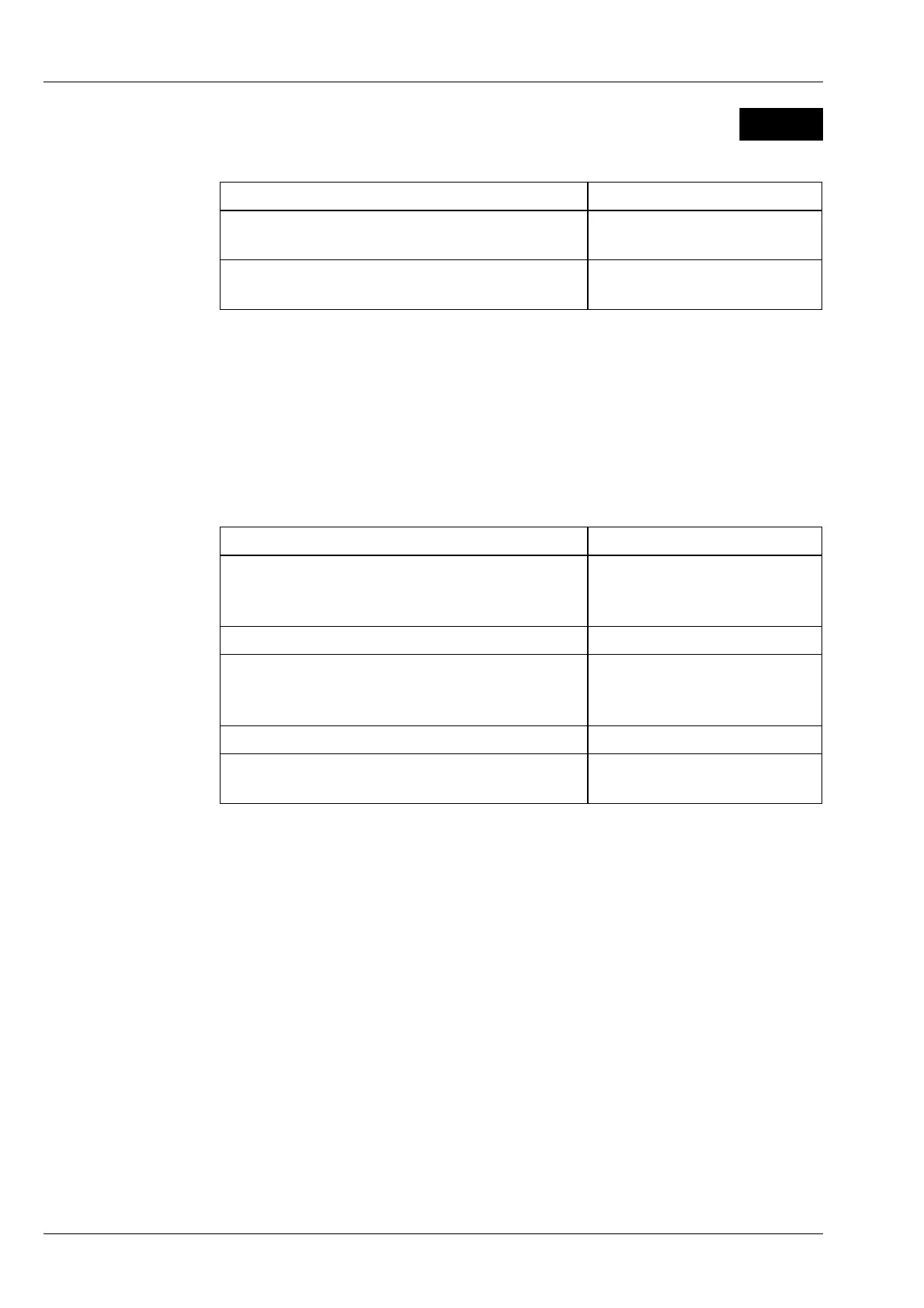

Designation GROVE part no.

Grease spray gun, complete:

Mobile, external compressed air connection

required

03325445

Spray extension, length 2 m, splittable 04159862

Manual grease spray gun for cartridge:

Via the tyre inflator connection on the truck

crane

03329027

25 m hose for manual grease spray gun: 03329072

Slide paste for the telescopic slide faces:

PAL1, 400 ml cartridge, refillable

03329071

Loading...

Loading...