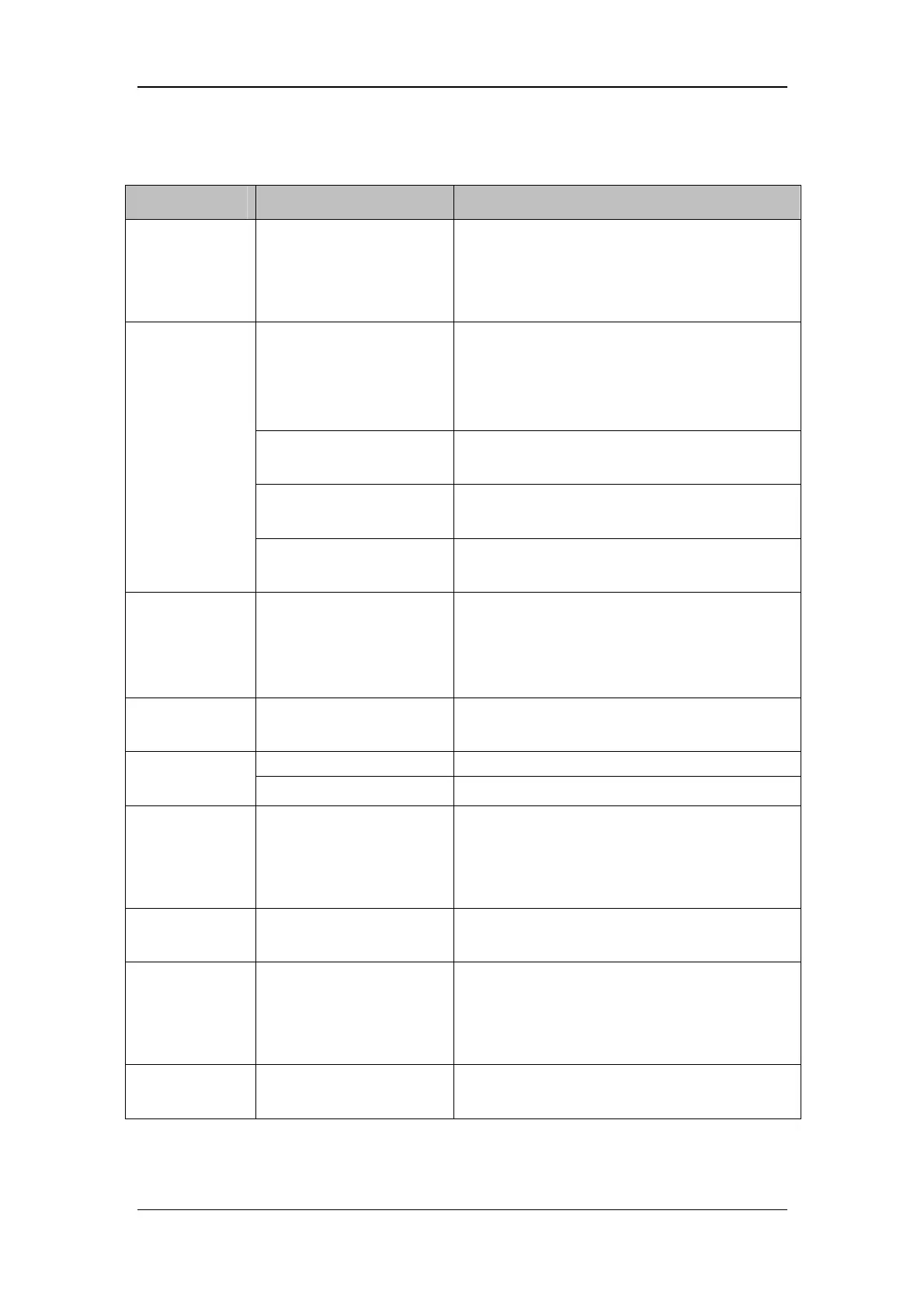

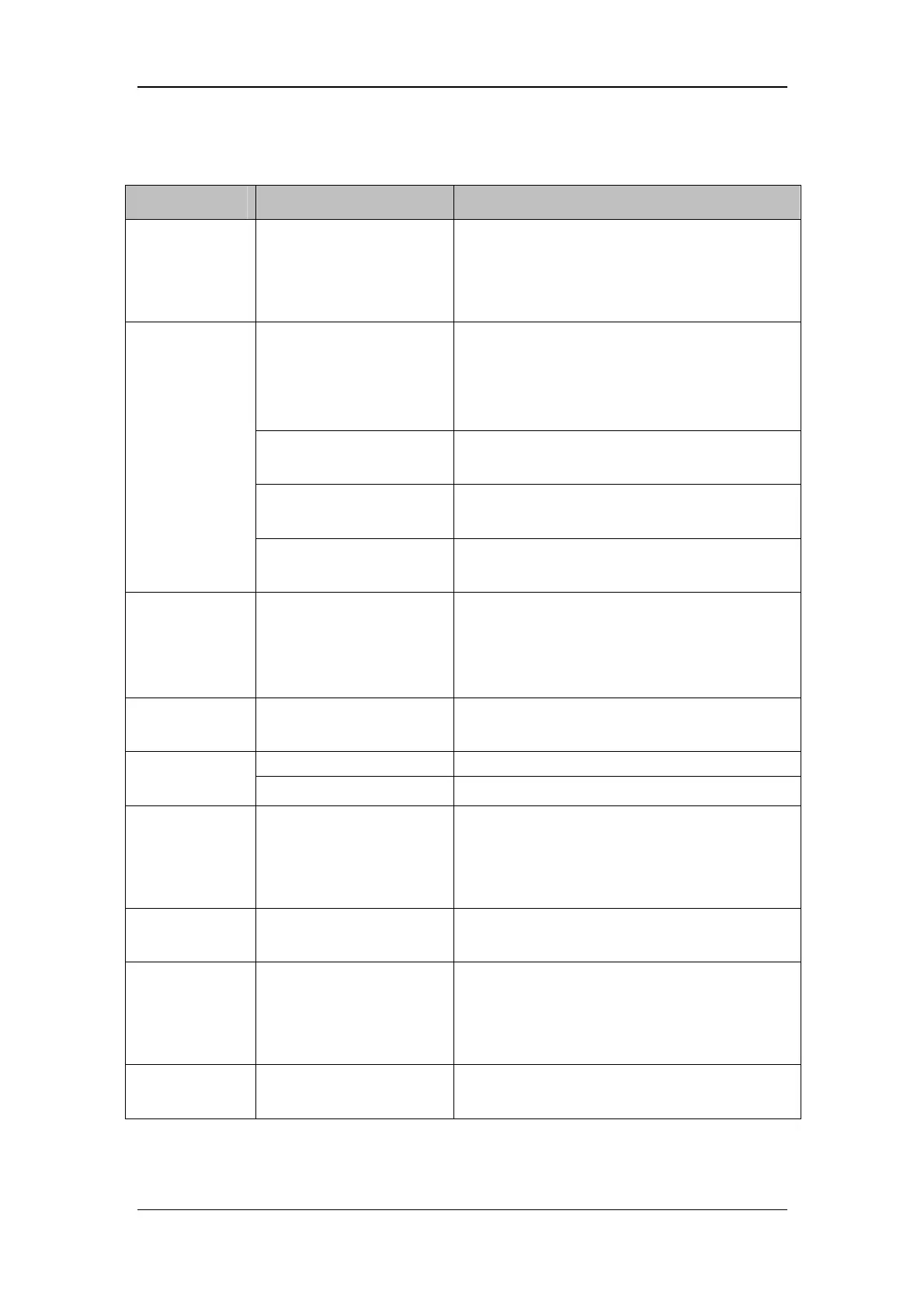

12-2

12.2 Maintenance Schedule

Interval Part/accessory Procedure

Each patient or

as necessary

Patient tubing (including

mask, inspiratory filter,

flow sensor, expiration

valve and membrane)

Perform pressure and flow zeroing. Perform

System Check. Perform flow sensor calibration

(refer to 12.4). Replace with disinfected parts or

new disposable parts.

As necessary Inspiration safety valve

assembly

When the patient’s exhaled gas may contaminate

the inspiration safety valve assembly, it is

necessary to replace with disinfected inspiration

safety valve and membrane (refer to 11.2.2).

Expiration valve Replace the expiration valve if it is damaged

(refer to 11.2.1).

CO

2

calibration Calibrate the CO

2

module when the CO

2

measured value has a great deviation.

Touch screen Calibrate the touch screen if its function is

degraded.

Several times a

day or as

necessary

Patient tubing Check the patient tubing and water traps for water

build-up. Empty water build-up if there is.

Inspect the parts for damage. Replace as

necessary.

During cleaning

and setup

Ventilator Inspect the parts for damage. Replace as

necessary.

Daily or as

necessary

Ventilator Clean the external surfaces.

O

2

cell Calibrate the O

2

cell.

Before each use

or after

continuous use

of two weeks

Entire ventilator Perform System Check. Check the breathing

system resistance and leakage.

Monthly or as

necessary

Air intake dust filter and

fan dust filter

Check the dust filter for dust build-up. Clean or

replace as necessary (refer to 11.2.4).

Check every 6

months and

replace every

two years

Lithium battery Check the charging and discharging of the lithium

battery every 6 months and replace the lithium

battery every two years. Contact us for

replacement.

Annually or as

necessary

Inspiration safety valve

membrane

Check the inspiration safety valve membrane.

Contact us for replacement if necessary.

Loading...

Loading...