_i

Chapter 12 Chassis electrical system

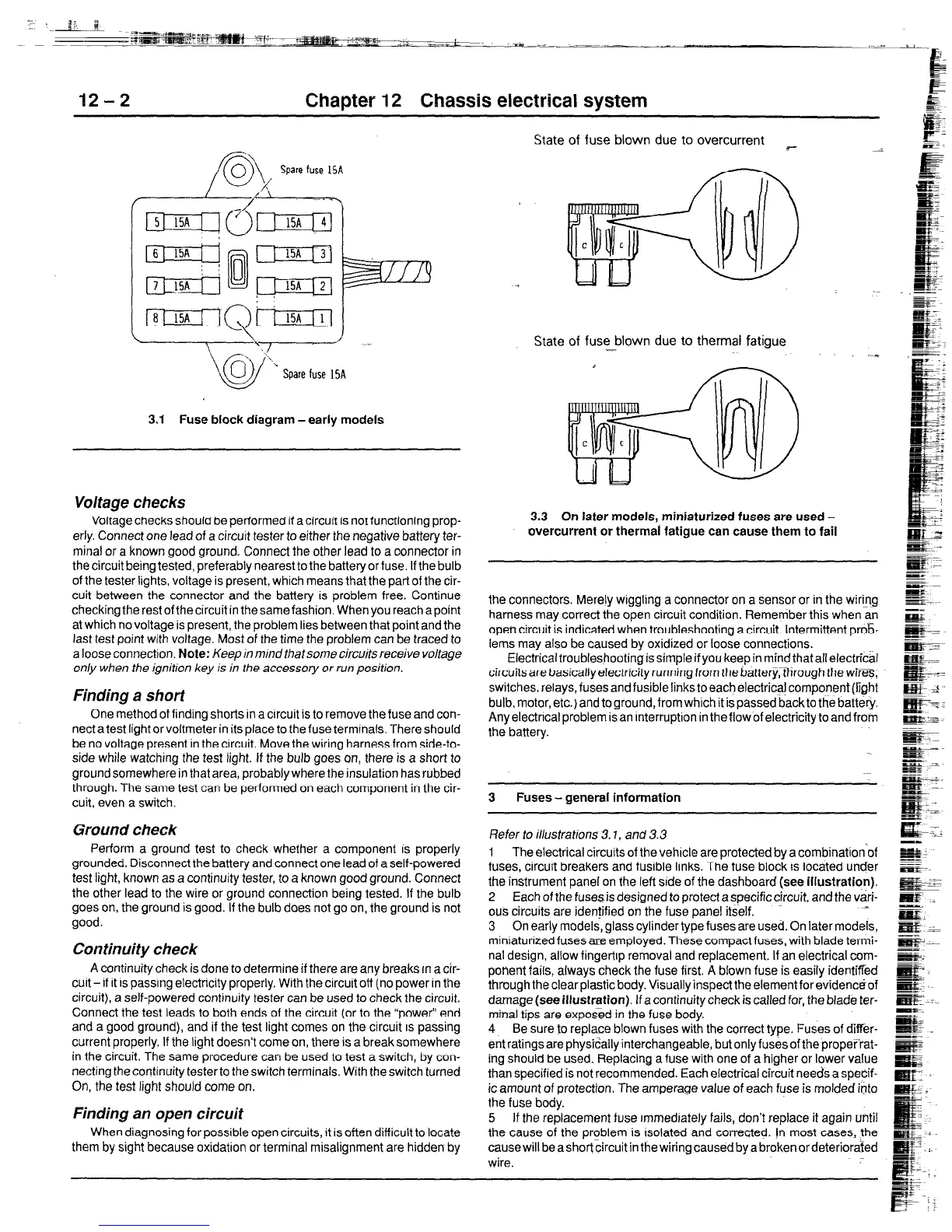

Spare fuse 15A

3.1 Fuse block diagram -early models

Voltage checks

Voltage checks should be performed if acircuit is not functioning prop-

erly. Connect one lead of a circuit tester to either the negative battery ter-

minal or a known good ground. Connect the other lead to a oonnector in

the circuit being tested, preferably nearest to the battery or fuse. If the bulb

of the tester lights. voltage is present, which means that the part of the cir-

cuit between the connector and the battery is problem free. Continue

checking therestofthecircuit in thesamefashion. When you reach apoint

at which no voltage is present, the problem lies between that point and the

last test point with voltage. Most of the time the problem can be traced to

a loose connection. Note: Keep in m/ndthatsome circuits receive voltage

only when the ignition key is in the accessory or run position.

Finding a short

One method of finding shorts in a circuit is to remove the fuse and con-

nect a test light or voltmeter in its place to the fuse terminals. There should

be no voltage present in the circuit. Move the wiring harness from side-to-

side while watching the test light. If the bulb goes on, there is a short to

ground somewhere in that area, probably where the insulation has rubbed

through. The same test can be performed on each component in the cir-

cuit, even a switch.

Ground check

Perform a ground test to check whether a component is properly

grounded. Disconnect the battery and connect one lead of a self-powered

test light, known as a continuity tester, to a known good ground. Connect

the other lead to the wire or ground connection being tested. If the bulb

goes on, the ground is good. If the bulb does not go on, the ground is not

good.

Continuity check

A continuity check is done to determine if there are any breaks rn a cir-

cuit - if it is passing electricity properly. With the circuit off (no power in the

circuit), a self-powered continuity tester can be used to check the circuit.

Connect the test leads to both ends of the circuit (or to the “power” end

and a good ground), and if the test light comes on the circuit IS passing

current properly. If the light doesn’t come on, there is a breaksomewhere

in the circuit. The same procedure can be used to test a switch, by con-

necting the continuity tester to the switch terminals. With the switch turned

On, the test light should come on.

Finding an open circuit

When diagnosing for possible open circuits, it is often difficult to locate

them by sight because oxidation or terminal misalignment are hidden by

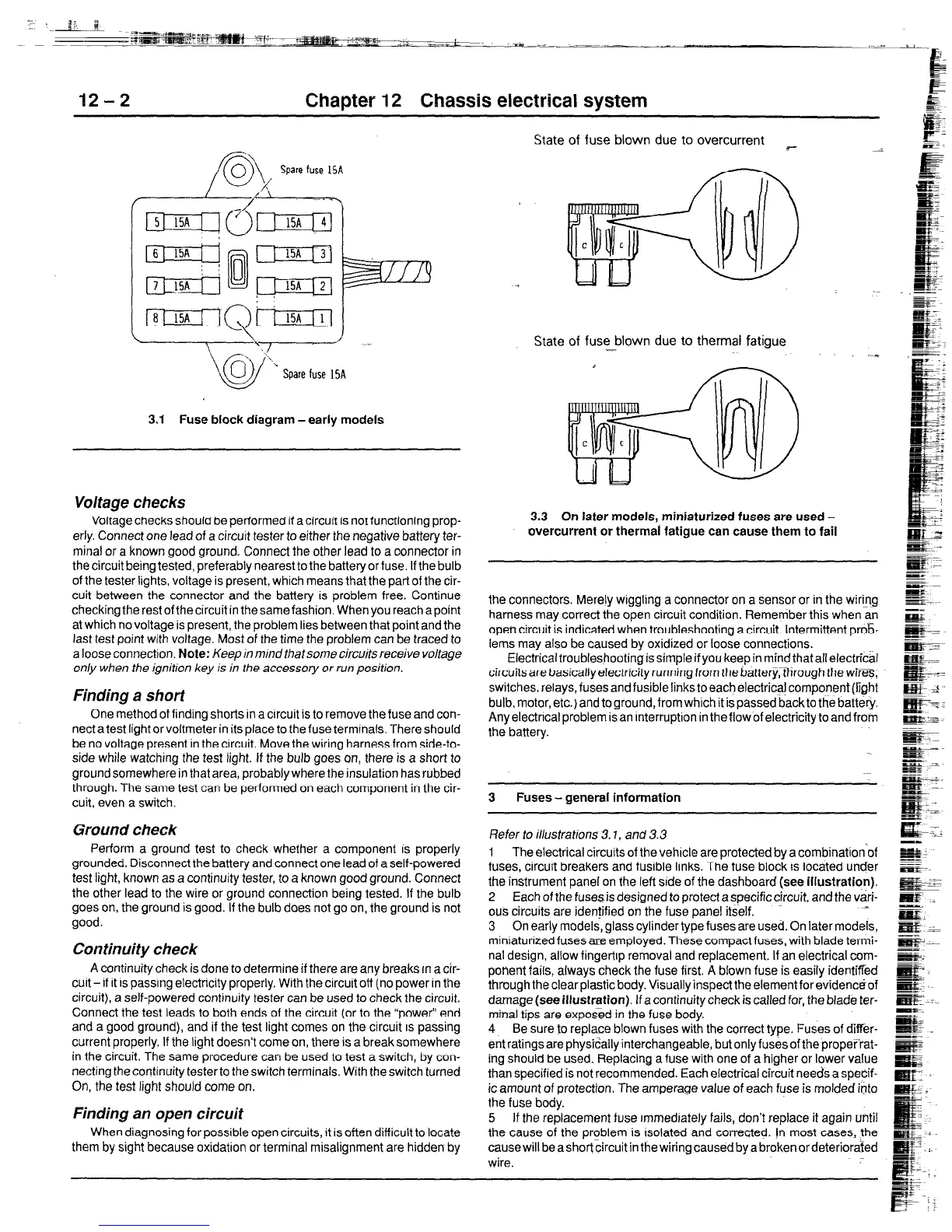

State of fuse

blown

due to overcurrent ~-

State of fuse blown due to thermal fatigue

-*

3.3 On later models, miniaturized fuses

are

used -

overcurrent or thermal fatigue can cause them to fail

the connectors. Merely wiggling a connector on a sensor or in the wiring

harness may correct the open circuit condition.

Remember

this when an

open circuit is indicated when troubleshooting a circuit. Intermittent pro&

lems may also be caused by oxidized or loose connections.

Electrical troubleshooting is simple if you keep in mind that all electrical

circuits are basically electricity running from the batteryythrough the wZ%,

switches. relays, fuses and fusible links to each electrica! component (fight

bulb, motor, etc.) and to ground, from which it is passed backto the battery.

Any electrical problem is an interruption in the flow of electricity to and from

the battery.

3 Fuses - general information

Refer to illustrations 3.7, and 3.3

1 The electrical circuits of the vehicle are protected by a combination of

fuses, circuit breakers and fusible links. The fuse block is

located under

the instrument panel on the left side of the dashboard (see illustration).

2 Each of the fuse@ designed to protect a specific circuit, and the vari-

ous circuits are identified on the fuse panel itself.

3 On early models, glass cylinder type fuses are used. On later

models,

miniaturized fuses are employed. These compact fuses, with blade termi-

nal design, allow fingertrp removal and replacement. If an electrical com-

ponent fails, always check the fuse first. A blown fuse is easily identified

through the clear plastic body. Visually inspect the element for

evidenciof

damage

(see illustration). If a continuity check is called for, the blade ter-

minal tips are exposed in the fuse body.

4 Be sure to replace blown fuses with the correct type. Fuses of

difkr-

ent ratings are physically interchangeable, but only fuses of the propet%%-

ing should be used. Replacing a fuse with one of a higher or lower value

than specified is not recommended. Each electrical circuit needs a specif-

ic amount of protection. The amperage

value of each

fuse

is molded into

the fuse body.

5 If the replacement fuse rmmedrately fails, don’t replace it again until

the cause of the problem is rsolated and corrected. In most cases, the

causewill beashortcircuit in thewiring

causedbya

brokenordeteriorated

wire.

Loading...

Loading...