2C-14

Chapter 2 Part C 3.OL V6 engine

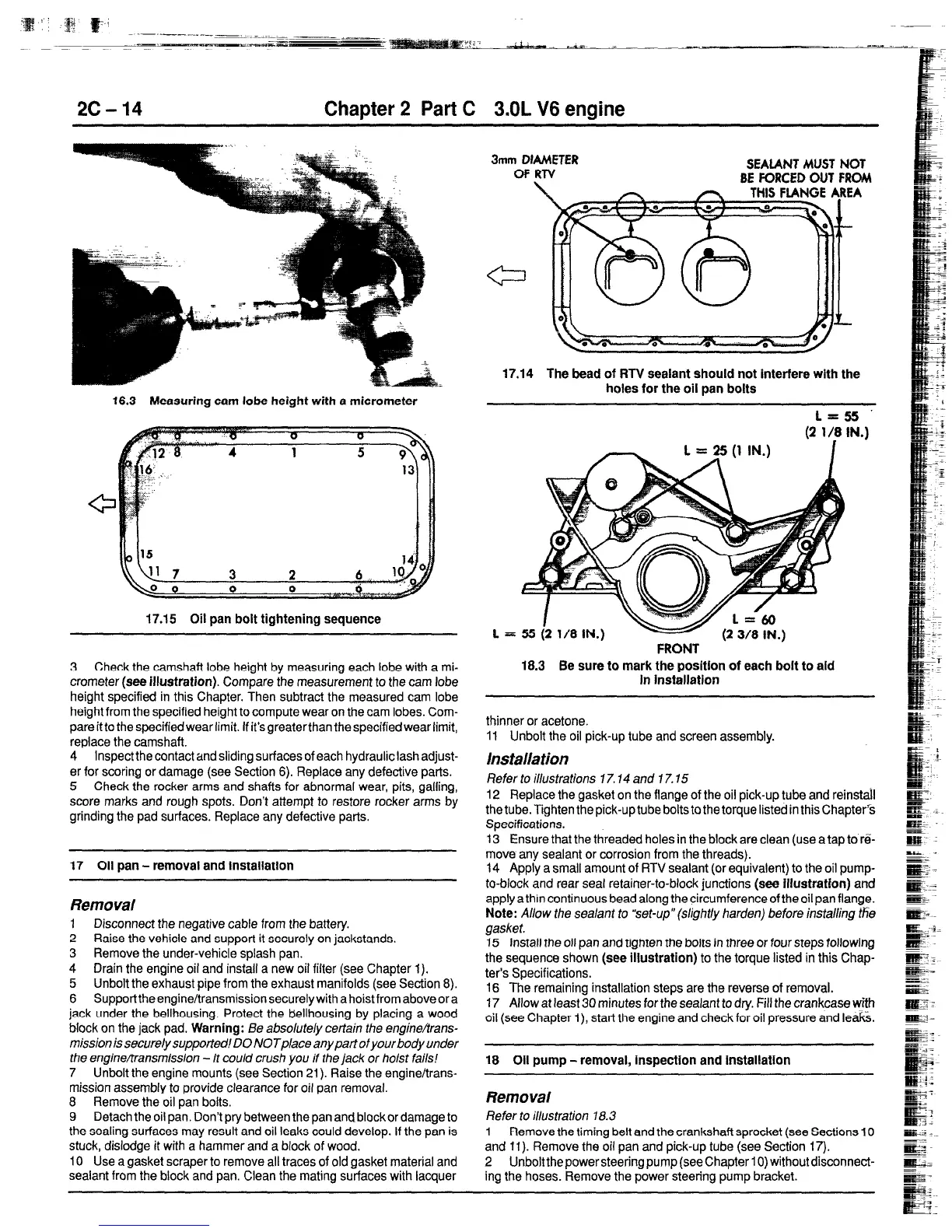

16.3 Measuring cam lobe height with a micrometer

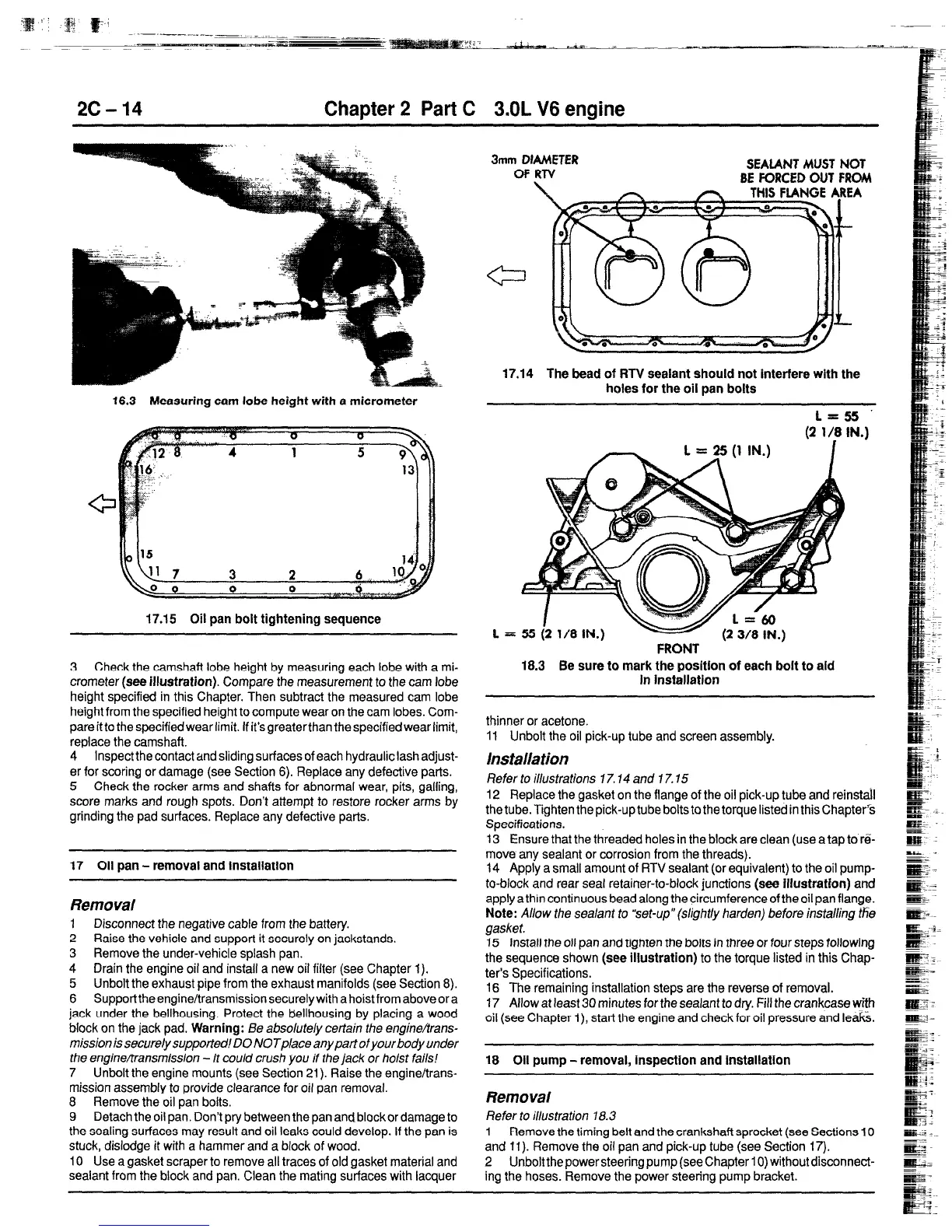

17.15 Oil pan bolt tightening sequence

3 Check the camshaft lobe height by measuring each lobe with a mi-

crometer

(see illustration).

Compare the measurement to the cam lobe

height specified in this Chapter. Then subtract the measured cam lobe

height from the specified height to compute wear on the cam lobes. Com-

pare it to the specifiedwear limit. If it’s greaterthan the specifiedwear limit,

replace the camshaft.

4

Inspect the contact and sliding surfaces of each hydraulic lash adjust-

er for scoring or damage (see Section 6). Replace any defective parts.

5 Check the rocker arms and shafts for abnormal wear, pits, galling,

score marks and rough spots. Don’t attempf to restore rocker arms by

grinding the pad surfaces. Replace any defective parts.

17 Oil pan - removal and installation

Removal

1 Disconnect the negative cable from the battery.

2 Raise the vehicle and support it securely on jackstands.

3 Remove the under-vehicle splash pan.

4

Drain the engine oil and install a new oil filter (see Chapter 1).

5 Unbolt the exhaust pipe from the exhaust manifolds (see Section 8).

6 SupporttheengineAransmission securely with a hoist from above or a

jack under the bellhousing. Protect the bellhousing by placing a wood

block on the jack pad.

Warning:

Be absolutely cerfain the engine/trans-

missionis securely supported! DO NOTplace anypartofyourbodyunder

the engine/transmission - it could crush you if the jack or hoist fails!

7 Unbolt the engine mounts (see Section 21). Raise the engineffrans-

mission assembly to provide clearance for oil pan removal.

8 Remove the oil pan bolts.

9

Detach the oil pan. Don’t pry between the pan and block or damage to

the sealing surfaces may result and oil leaks could develop. If the pan is

stuck, dislodge it with a hammer and a block of wood,

10 Use a gasket scraper to remove all traces of old gasket material and

sealant from the block and pan. Clean the mating surfaces with lacquer

3mm DIAMETER

OFRTV

SEALANT

MUST NOT

BE FORCED OUT FROM

17.14 The bead of RTV sealant should not interfere with the

holes for the oil pan bolts

FRONT ’

18.3 Be sure to mark the positlon of each bolt to aid

In Installation

thinner or acetone.

11 Unbolt the oil pick-up tube and screen assembly.

Installation

Refer to illustrations 17.14 and 17.15

12 Replace the gasket on the flange of the oil pick-up tube and reinstall

the tube. Tighten the pick-up tube bolts to the torque listed in this Chapter’%

Specifications.

13 Ensure that the threaded holes in the block are clean (use atap to re-

move any sealant or corrosion from the threads).

14 Apply a small amount of RTV sealant (or equivalent) to the oil pump-

to-block and rear seat retainer-to-block junctions

(see illustration)

and

apply a thin continuous bead along the circumference of the oil pan flange.

Note:

Allow the sealant to “set-up” (slightly harden) before installing #Ye

gasket.

15 Install the oil pan and tighten the bolts in three or four steps following

the sequence shown

(see illustration)

to the torque listed in this Chap-

ter’s Specifications.

16 The remaining installation steps are the reverse of removal.

17 Allow at least 30 minutes for the sealant to dry. Fill the crankcase with

oil (see Chapter i), start the engine and check for oil pressure and leaf&

18 Oil pump - removal, inspection and instalfatlon

Removal

Refer to illustration 18.3

1

Remove the timing belt and the crankshaft sprocket (see Sections 10

and 11). Remove the oil pan and pick-up tube (see Section 17).

2 Unboltthepowersteering pump (seechapter 10) withoutdisconnect-

ing the hoses. Remove the power steering pump bracket.

Loading...

Loading...