Chapter 2 Part C 3.OL V6 engine 2C-15

8

6’ ‘7

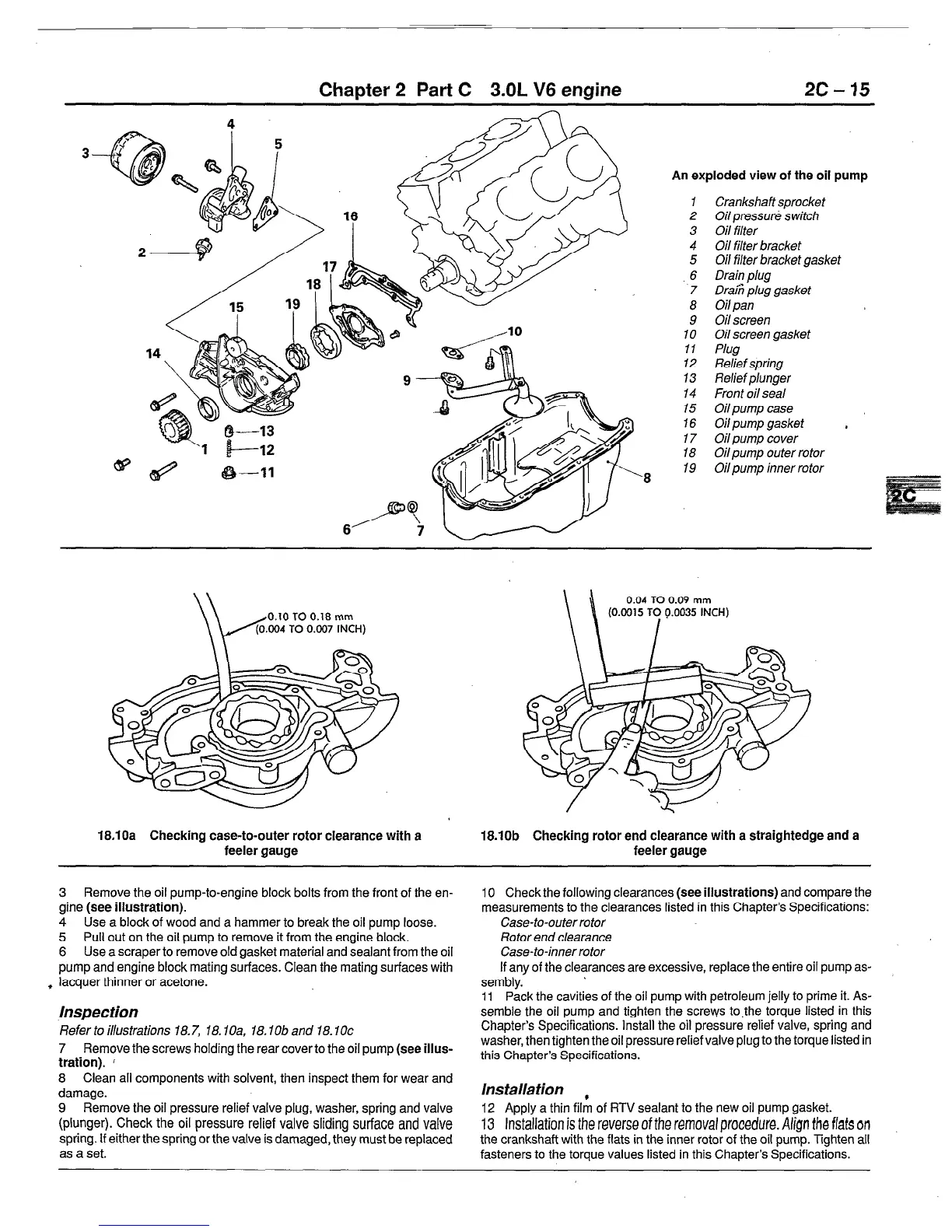

An exploded view of the oil pump

1

Crankshaft sprocket

2 Oil pressure switch

3 Oil filter

4 Oil filter bracket

5 Oil filter bracket gasket

.6

Drain plug

7 Draiii plug gasket

8 Oil pan

9 Oil screen

10 Oil screen gasket

11

Plug

12

Relief spring

13

Relief

plunger

14 Front oil seal

15

Oil pump case

16

Oil

pump gasket ,

17 Oil pump cover

18 Oil pump outer rotor

19 Oil pump inner rotor

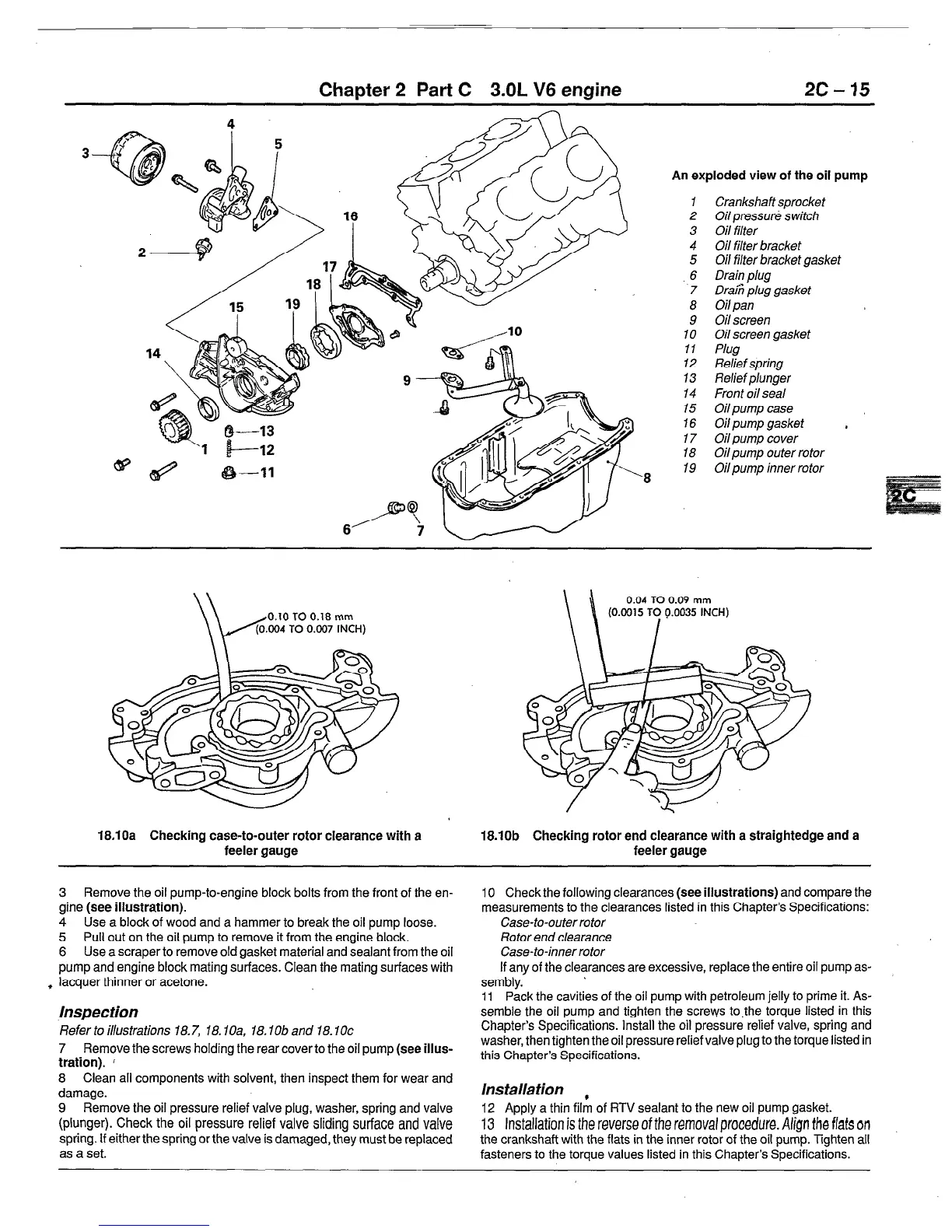

0.10 TO 0.18 mm

\\

0.04 TO 0.09 mm

(0.0015 TO 9.0035 INCH)

I

18.10a Checking case-to-outer rotor clearance with a

feeler gauge

3 Remove the oil pump-to-engine block bolts from the front of the en-

gine (see

illustration).

4 Use a block of wood and a hammer to break the oil pump loose.

5 Pull out on the oil pump to remove it from the engine block.

6 Use a scraper to remove old gasket material and sealant from the oil

pump and engine block mating surfaces. Clean the mating surfaces with

t lacquer thinner or acetone.

Inspection

Refer to illustrations 18.7, 18. IOa, 18. lob and 18.10~

7 Remove the screws holding the rear cover to the oil pump

(see iiius-

tration). i

8 Clean all components with solvent, then inspect them for wear and

damage.

9 Remove the oil pressure relief valve plug, washer, spring and valve

(plunger). Check the oil pressure relief valve sliding surface and valve

spring. If either the spring or the valve is damaged, they must be replaced

as a set.

18.10b Checking rotor end clearance with a straightedge and a

feeler gauge

10 Check the following clearances (see

illustrations)

and compare the

measurements to the clearances listed in this Chapter’s Specifications:

Case-to-outer rotor

Rotor end clearance

Case-to-inner rotor

If any of the clearances are excessive, replace the entire oil pump as-

sembly.

11 Pack the cavities of the oil pump with petroleum jelly to prime it. As-

semble the oil pump and tighten the screws to,the torque listed in this

Chapter’s Specifications. Install the oil pressure relief valve, spring and

washer, then tighten the oil pressure relief valve plug to the torque listed in

this Chapter’s Specifications.

Ins talla tion

12 Apply a thin fillfl of RTV sealant to the new oil pump gasket.

13 Installation is the reverse of the removal procedure. Align the flats on

the crankshaft with the flats in the inner rotor of the oil pump. Tighten all

fasteners to the torque values listed in this Chapter’s Specifications.

Loading...

Loading...