Chapter 2 Part C 3.OL V6 engine

2C-5

surfaces with lacquer thinner or acetone. If there’s sealant or oil on the -

mating surfaces when the cover is installed, oil leaks may develop.

15 If necessary, clean the mounting screw threads with a die to remove

any corrosion and restore damaged threads. Make sure the threaded

holes in the head are clean -run a tap into them to remove corrosion and

restore damaged threads.

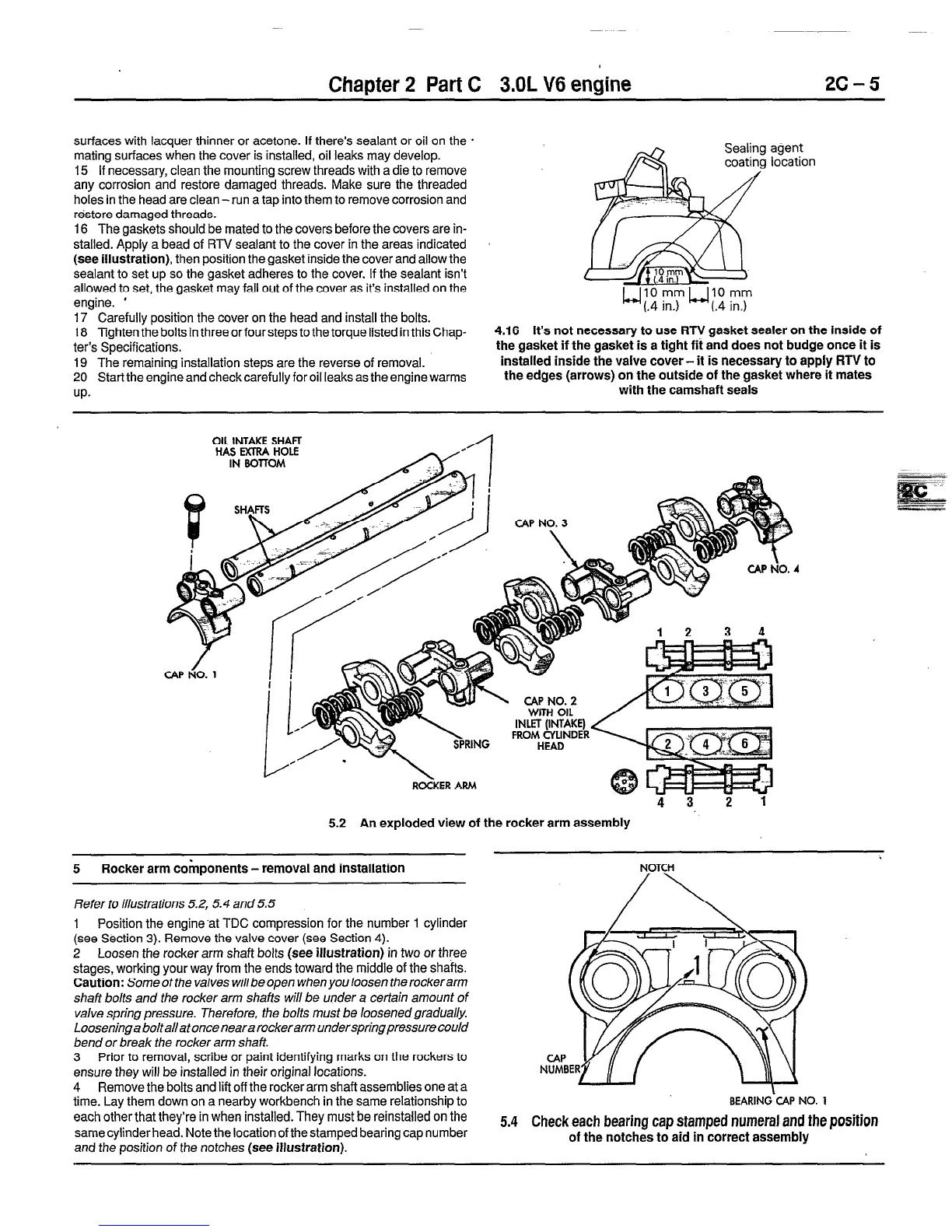

16 The gaskets should be mated to the covers before the covers are in-

stalled. Apply a bead of RTV sealant to the cover in the areas indicated

(see illustration),

then position the gasket inside the cover and allow the

sealant to set up so the gasket adheres to the cover. If the sealant isn’t

allowed to set, the gasket may fall out of the cover as it’s installed on the

engine. *

17 Carefully position the cover on the head and install the bolts.

18 Tighten the boltsin three or four steps to the torque listed in this Chap-

ter’s Specifications.

19 The remaining installation steps are the reverse of removal.

20 Start the engine and check carefully for oil leaks as the engine warms

up.

Sealing

coating

A

agent

location

4.16 it’s not necessary to use RIV gasket sealer on the inside of

the gasket if the gasket is a tight fit and does not budge once it is

installed inside the valve cover - it is necessary to apply RTV to

the edges (arrows) on the outside of the gasket where it mates

with the camshaft seals

OIL INTAKE WAR

HAS EXI-RA HOLE

IN BOTrOM

43 2 1

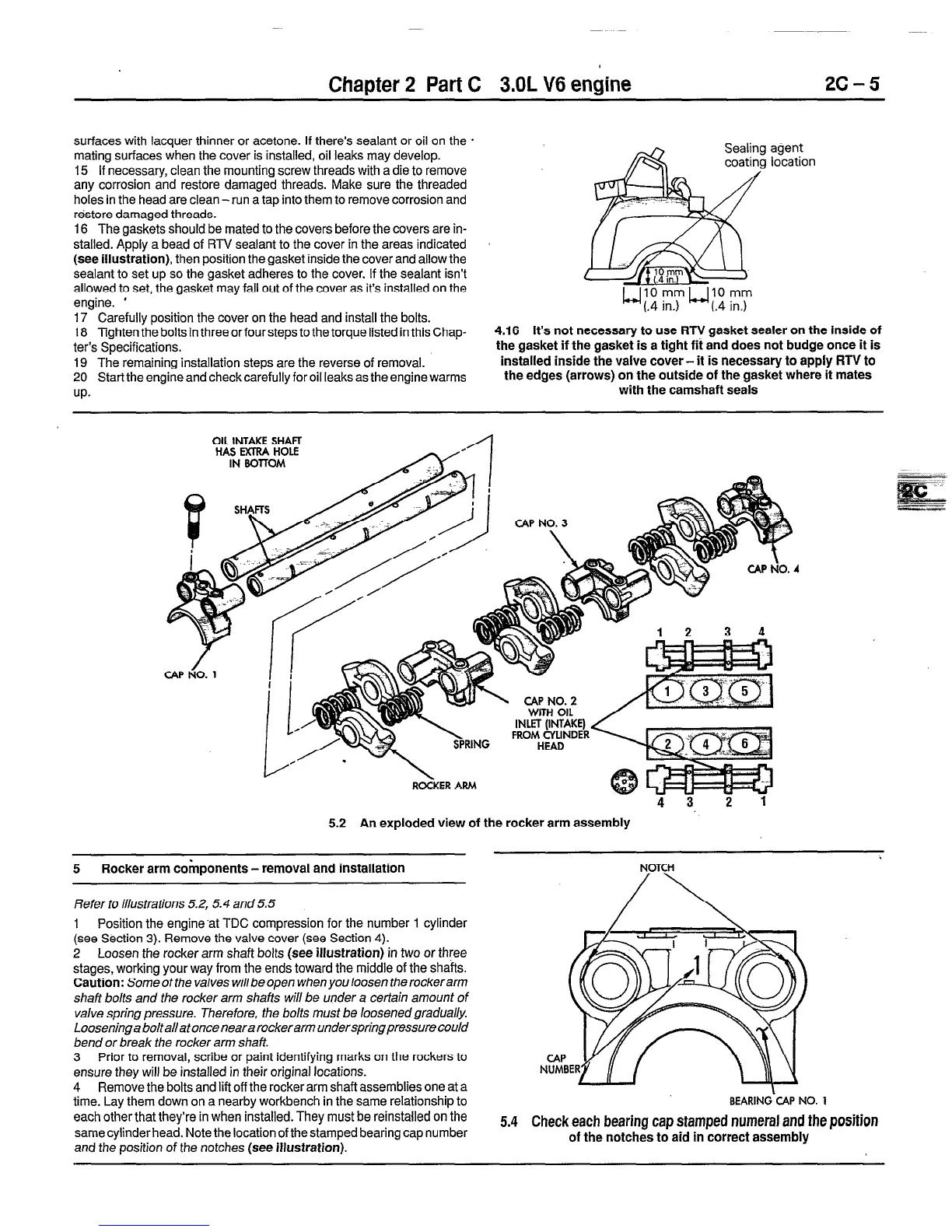

5.2 An exploded view of the rocker arm assembly

5 Rocker arm components-removal and installation

NOTCH

/\

Refer to illustrations 5.2, 5.4 and 5.5 / \

1 Position the engine‘at TDC compression for the number 1 cylinder

(see Section 3). Remove the valve cover (see Section 4).

2 Loosen the rocker arm shaft bolts

(see illustration)

in two or three

stages, working your way from the ends toward the middle of the shafts.

Caution:

Some of fbe valves willbe open when you loosen the rockerarm

shaft bolts and the rocker arm shafts will be under a certain amount of

valve spring pressure. Therefore, the bolts must be loosenedgradually.

Loosening a boltallat once neara rockerarm underspringpressure could

bend or break the rocker arm shaft.

3 Prior to removal, scribe or paint identifying marks on the rockers to

ensure they will be installed in their original locations.

4 Remove the bolts and lift off the rocker arm shaft assemblies one at a

time. Lay them down on

a

nearby workbench in the same relationship to

each otherthat they’re in when installed. They must be reinstalled on the

same cylinder head. Note the location of the stamped bearing cap number

and the position of the notches

(see illustration).

5.4

BEARING-CAP NO. 1

Check each bearing cap stamped numeral and the position

of the notches to aid in correct assembly

Loading...

Loading...