2A-16 Chapter 2 Part A 2.6L four-cylinder engine

16.7 Check the driven gear-to-housing

16.8 Check the drive gear-to-housing

16.9 Remove the oil pressure relief

clearance clearance valve spring and measure Its free length

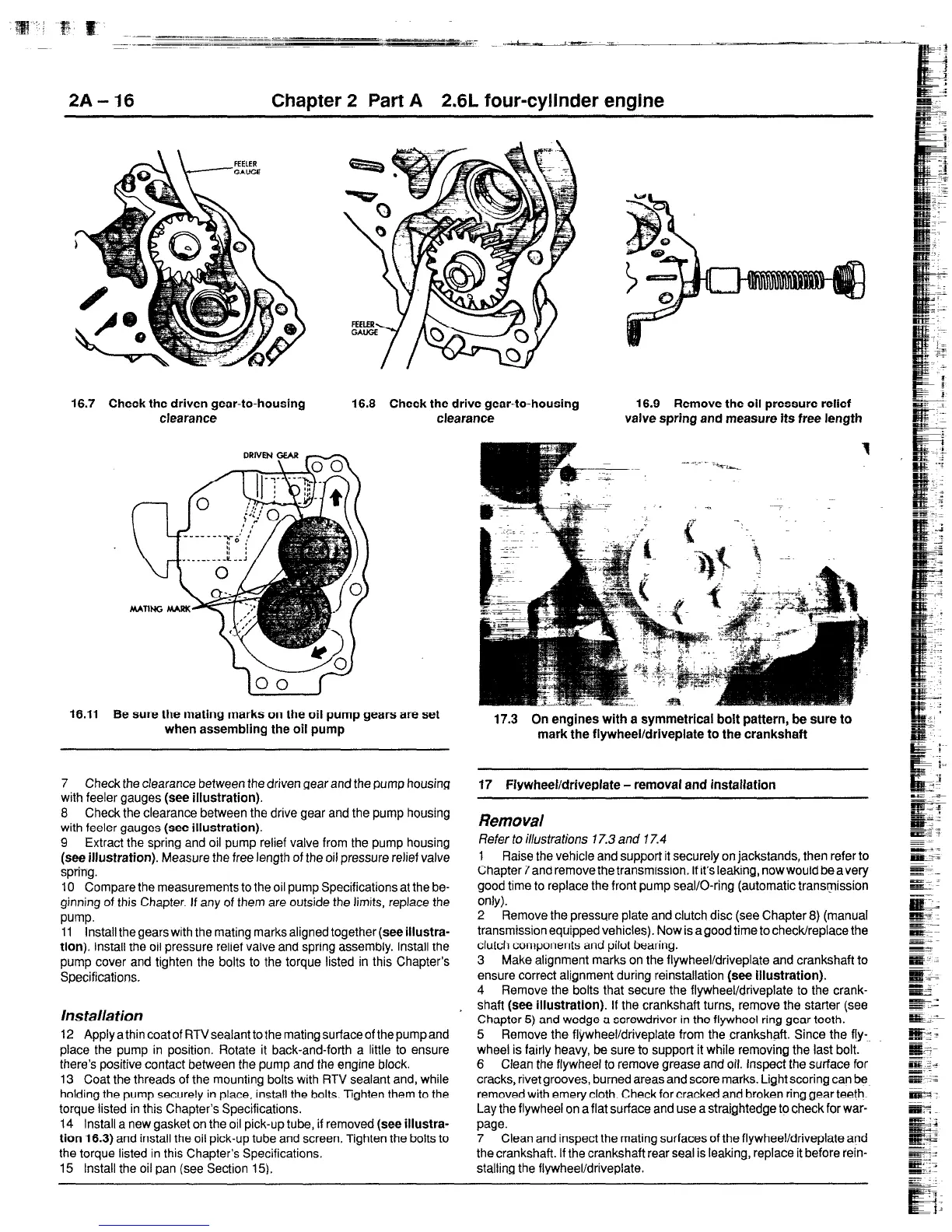

16.11 Be sure the mating marks on the oil pump gears are set

when assembling the oil pump

7 Check the clearance between the driven gear and the pump housing

with feeler gauges

(see illustration).

8 Check the clearance between the drive gear and the pump housing

with feeler gauges

(see illustration).

9 Extract the spring and oil pump relief valve from the pump housing

(see illustration).

Measure the free length of the oil pressure relief valve

spring.

IO Compare the measurements to the oil pump Specifications at the be-

ginning of this Chapter. If any of them are outside the limits, replace the

pump.

11 install thegearswith the mating marks aligned together(see

illustra-

tion).

Install the oil pressure relief valve and spring assembly. Install the

pump cover and tighten the bolts to the torque listed in this Chapter’s

Specifications.

Ins talla tion

12 ApplyathincoatofRTVsealanttothematingsurfaceofthepumpand

place the pump in position. Rotate it back-and-forth a little to ensure

there’s positive contact between the pump and the engine block.

13 Coat the threads of the mounting bolts with RTV sealant and, while

holding the pump securely in place, install the bolts. Tighten them to the

torque listed in this Chapter’s Specifications.

14 Install a new gasket on the oil pick-up tube, if removed

(see illustra-

tion 16.3)

and install the oil pick-up tube and screen. Tighten the bolts to

the torque listed in this Chapter’s Specifications.

15 Install the oil pan (see Section 15).

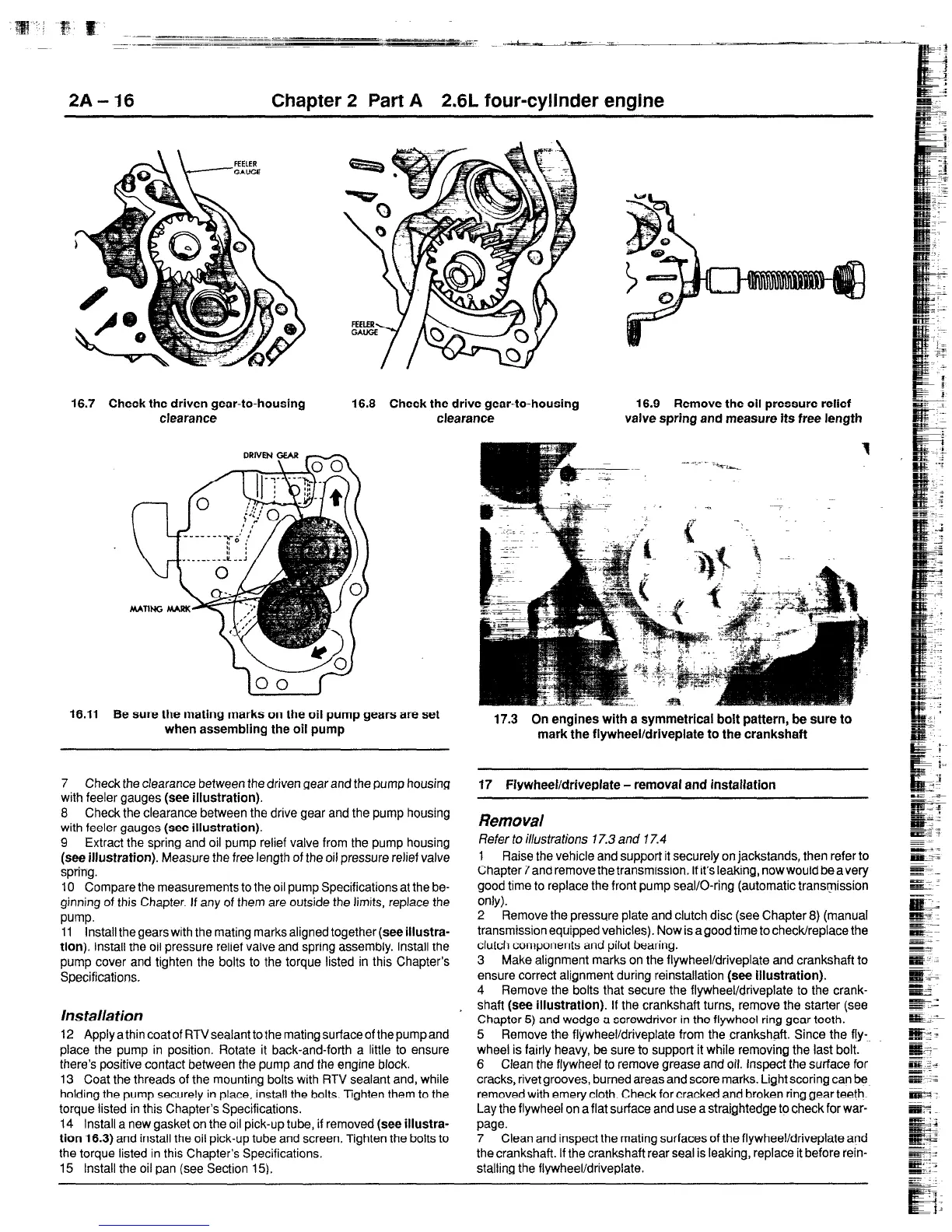

17.3 On engines with a symmetrical bolt pattern, be sure to

mark the flywheel/driveplate to the crankshaft

17 FlywheeVdriveplate - removal and inslallation

Removal

Refer to illustrations 17.3 and 17.4

1 Raise the vehicle and support it securely on jackstands, then refer to

Chapter 7and remove the transmission. If it’s leaking, now would be a very

good time to replace the front pump seal/O-ring (automatic transmission

only).

2 Remove the pressure plate and clutch disc (see Chapter 8) (manual

transmission equipped vehicles). Now is a good time to check/replace the

clutch components

and

pilot bearing.

3 Make alignment marks on the flywheel/driveplate and crankshaft to

ensure correct alignment during reinstallation

(see illustration).

4 Remove the bolts that secure the flywheel/driveplate to the crank-

shaft

(see illustration).

If the crankshaft turns, remove the starter (see

Chapter 5) and wedge a screwdriver in the flywheel ring gear teeth.

5 Remove the flywheel/driveplate from the crankshaft. Since the fb-

wheel is fairly heavy, be sure to support it while removing the last bolt.

6 Clean the flywheel to remove grease and ofl. Inspect the surface for

cracks, rivet grooves, burned areas and score marks. Light scoring can be

removed with emery cloth. Check for cracked and broken ring gear teeth.

Lay the flywheel on a flat surface and

use a

straightedge to check for war-

paw.

7 Clean and inspect the mating surfaces of the flywheel/driveplate and

the crankshaft. If the crankshaf? rear seal is leaking, replace it before rein-

stalling the fiywheelidriveplate.

Loading...

Loading...