Chapter 2 Part A 2.6L four-cylinder engine

2A-7

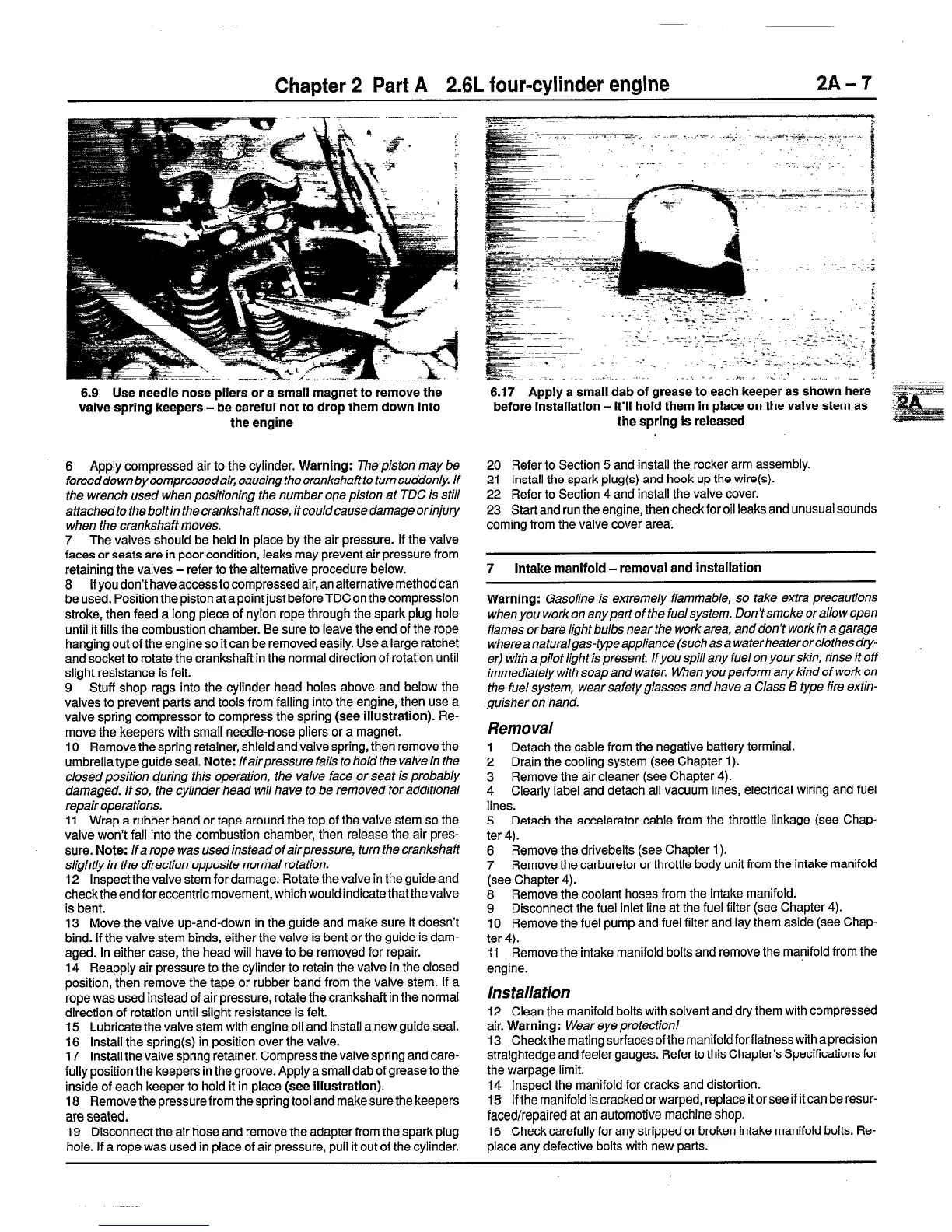

6.9 Use needle nose pliers or a small magnet to remove the

valve spring keepers - be careful not to drop them down into

the engine

6 Apply compressed air to the cylinder. Warning: The piston may be

forceddownbycompressedair, causing thecrankshaftto turnsuddenly. If

the wrench used when positioning the number one piston at TDC is still

attached to the bolt in the crankshaft nose, it couldcause damage or injury

when the crankshaft moves.

7 The valves should be held in place by the air pressure. If the valve

faces or seats are in poor condition, leaks may prevent air pressure from

retaining the valves-refer to the alternative procedure below.

8 If you don’t have access to compressed air, an alternative method can

be used. Position the piston at a point just before TDC on the compression

stroke, then feed a long piece of nylon rope through the spark plug hole

until it fills the combustion chamber. Be sure to leave the end of the rope

hanging out of the engine so it can be removed easily. Use a large ratchet

and socket to rotate the crankshaft in the normal direction of rotation until

slight resistance is felt.

9 Stuff shop rags into the cylinder head holes above and below the

valves to prevent parts and tools from falling into the engine, then use a

valve spring compressor to compress the spring (see illustration). Re-

move the keepers with small needle-nose pliers or a magnet.

10 Remove the spring retainer, shield and valve spring, then remove the

umbrella type guide seal. Note: lfairpressure fails to hold the valvein the

closed position during this operation, the valve face or seat is probably

damaged. If so, the cylinder head will have to be removed for additional

repair operations.

11 Wrap a rubber band or tape around the top of the valve stem so the

valve won’t fall into the combustion chamber, then release the air pres-

sure. Note: If a rope was used instead of airpressure, turn the crankshaft

slightly in the direction opposite normal rotation.

12 Inspect the valve stem for damage. Rotate the valve in the guide and

checkthe end for eccentric movement, which would indicate that the valve

is bent.

13 Move the valve up-and-down in the guide and make sure it doesn’t

bind. If the valve stem binds, either the valve is bent or the guide is dam-

aged. In either case, the head will have to be removed for repair.

14 Reapply air pressure to the cylinder to retain the valve in the closed

position, then remove the tape or rubber band from the valve stem. If a

rope was used instead of air pressure, rotate the crankshaft in the normal

direction of rotation until slight resistance is felt.

15 Lubricate the valve stem with engine oil and install a new guide seal.

16 Install the spring(s) in position over the valve.

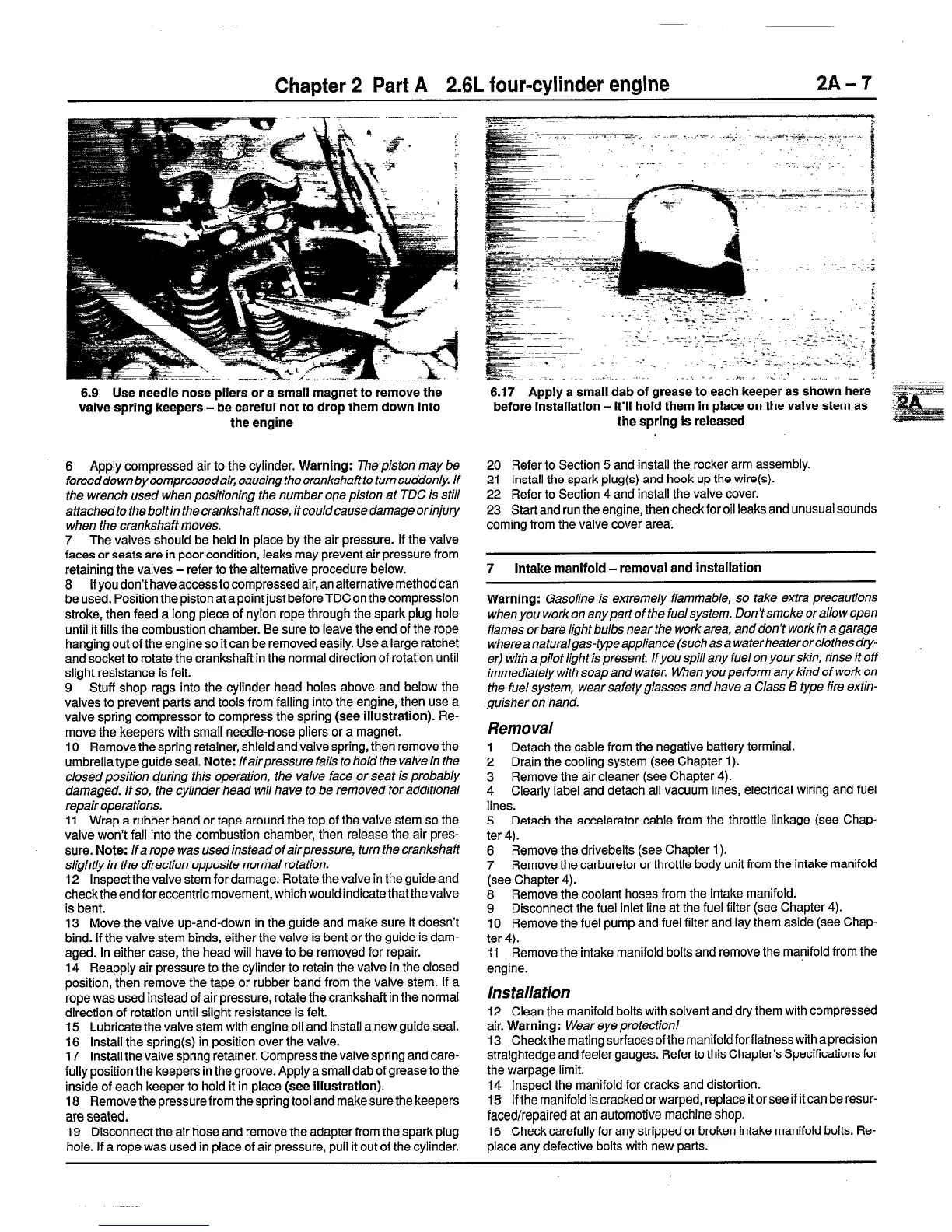

17 Install the valve spring retainer. Compress the valve spring and care-

fully position the keepers in the groove. Apply a small dab of grease to the

inside of each keeper to hold it in place (see illustration).

18 Remove the pressure from the spring tool and make sure the keepers

are seated.

19 Disconnect the air hose and remove the adapter from the spark plug

hole. If a rope was used in place of air pressure, pull it out of the cylinder.

..~. . -“. _ I. _ . __ .

6.17 Apply a small dab of grease to each keeper as shown here

before Installation - it’ll hold them in place on the valve stem as

the spring is released

20 Refer to Section 5 and install the rocker arm assembly.

21 Install the spark plug(s) and hook up the wire(s).

22 Refer to Section 4 and install the valve cover.

23 Start and run the engine, then check for oil leaks and unusual sounds

coming from the valve cover area.

7 Intake manifold - removal and installation

Warning: Gasoline is extremely flammable, so take extra precautions

when you work on anypart of the fuel system. Don’t smoke or allow open

flames or bare light bulbs near the work area, and don’t work in a garage

whereanaturalgas-typeappliance (suchasa waterheaterorclothesdry-

er) with a pilot light is present. lfyou spill any fuel on your skin, rinse it off

immediately with soap and water. When you perform any kind of work on

the fuel system, wear safety glasses and have a C/ass B type fire extin-

guisher on hand.

Removal

1 Detach the cable from the negative battery terminal.

2 Drain the cooling system (see Chapter 1).

3 Remove the air cleaner (see Chapter 4).

4 Clearly label and detach all vacuum lines, electrical wiring and fuel

lines.

5 Detach the accelerator cable from the throttle linkage (see Chap-

ter 4).

6 Remove the drivebelts (see Chapter 1).

7 Remove the carburetor or throttle body unit from the intake manifold

(see Chapter 4).

8 Remove the coolant hoses from the intake manifold.

9 Disconnect the fuel inlet line at the fuel filter (see Chapter 4).

10 Remove the fuel pump and fuel filter and lay them aside (see Chap-

ter 4).

11 Remove the intake manifold bolts and remove the manifold from the

engine.

Installation

12 Clean the manifold bolts with solvent and dry them with compressed

air. Warning: Wear eye protection!

13 Checkthematlngsurfacesofthemanifoldforflatnesswithaprecision

straightedge and feeler gauges. Refer to this Chapter’s Specifications for

the warpage limit.

14 Inspect the manifold for cracks and distortion.

15 If the manifold is cracked or warped, replace it or see if it can be resur-

faced/repaired at an automotive machine shop.

16 Check carefully for any stripped or broken intake manifold bolts. Re-

place any defective bolts with new parts.

Loading...

Loading...