7B-2

Chapter 7 Part B Automatic transmission

.

8

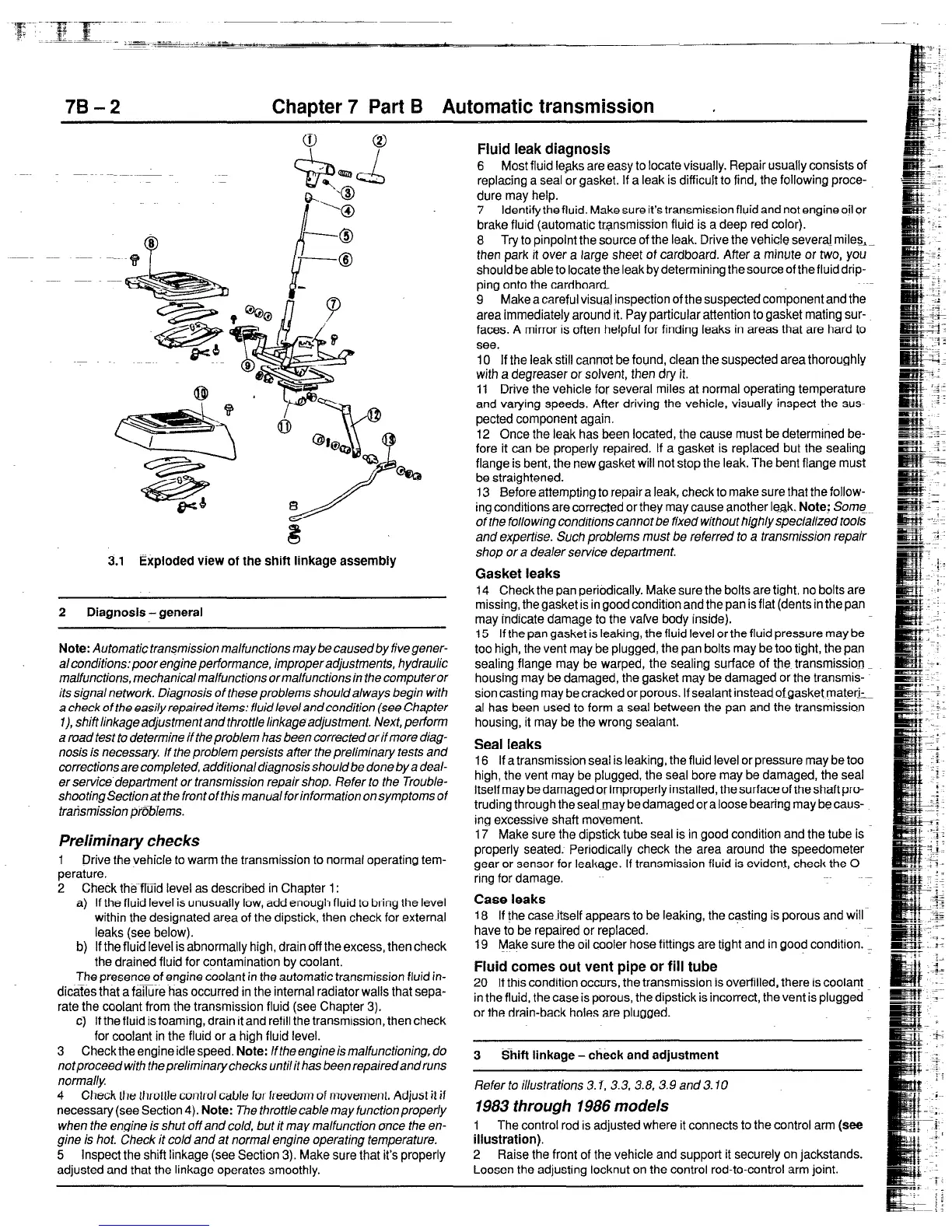

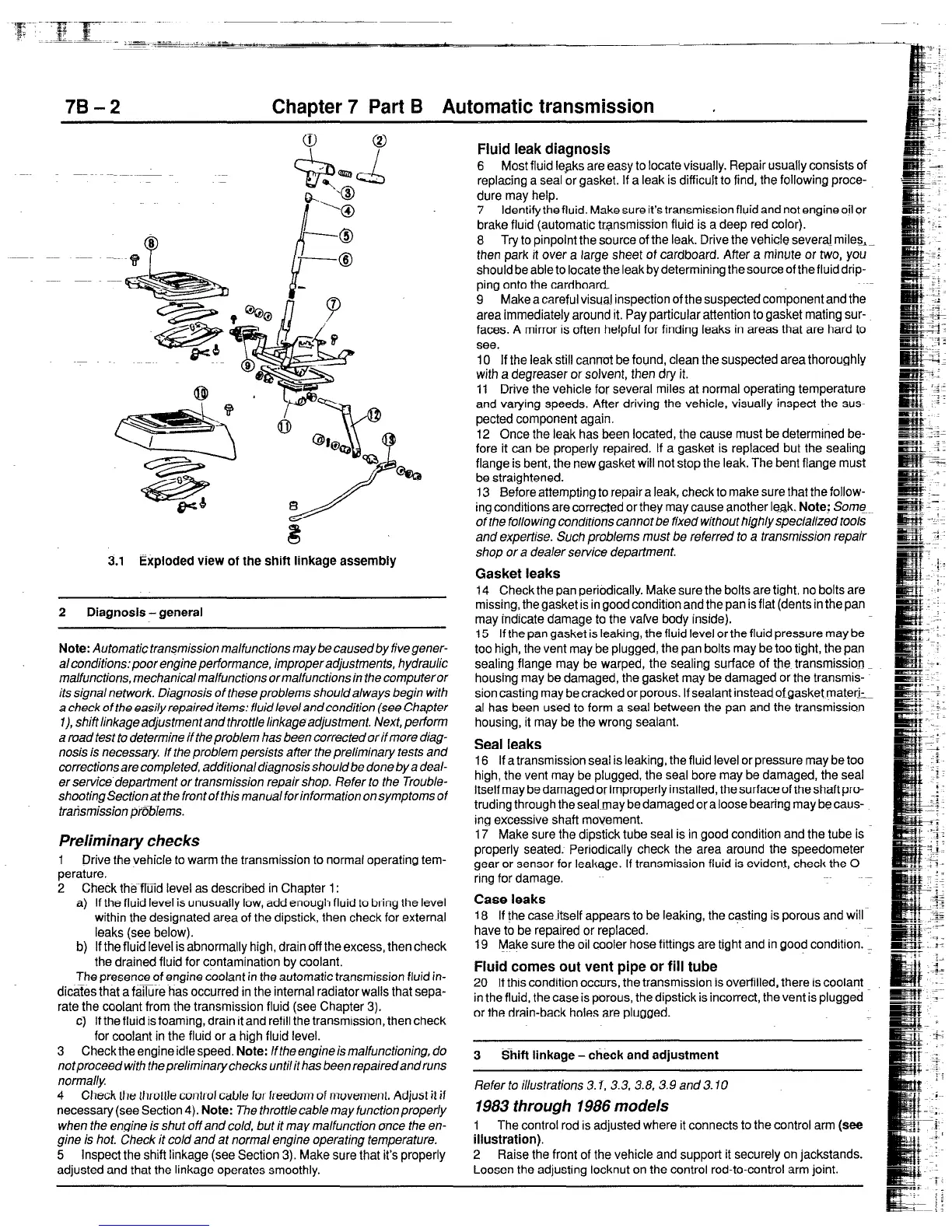

3.1 Exploded view of the shift linkage assembly

2 Diagnosis - general

Note:

Automatic transmission malfunctions may be caused by five gener-

al conditions: poor engine performance, improper adjustments, hydraulic

malfunctions, mechanical malfunctions ormalfunctions in the computeror

its signal network. Diagnosis of these problems should always begin with

a check of the easily repaireditems: fluid leveland condition (see Chapter

l), shift linkage adjustment and throttle linkage adjustment. Next, perform

a road test to determine if the problem has been corrected or if more diag

nosis is necessary. If the problem persists after the preliminary tests and

corrections are completed, additionaldiagnosis should be done by a deal-

er service.department or transmission repair shop. Refer to the Trouble-

shootingSectionat the frontofthis manualforinformationonsymptoms of

tratismission prbblems.

Preliminary checks

1 Drive the vehicle to warm the transmission to normal operating tem-

perature.

2 Check thNUid level as described in Chapter 1:

a) If the fluid level is unusually low, add enough fluid to bring the level

within the designated area of the dipstick, then check for external

leaks (see below).

b) If the fluid level is abnormally high, drain off the excess, then check

the drained fluid for contamination by coolant.

The presence of engine coolant in the automatic transmission fluid in-

ditties that a failure has occurred in the internal radiator walls that sepa-

rate the coolant from the transmission fluid (see Chapter 3).

c) If the fluid is foaming, drain it and refill the transmission, then check

for coolant in the fluid or a high fluid level.

3 Check the engine idle speed.

Note:

lfthe engineismalfunctioning, do

notproceed with the preliminary checks untilit has been repairedand runs

normally

4 Check the throttle control cable for freedom of movement. Adjust it if

necessary (see Section 4).

Note:

The thrott/e cab/e may function properly

when

the engine is shut off and co/d, but it may malfunction once the en-

gine is hot. Check it cold and at normal engine operating temperature.

5 Inspect the shift linkage (see Section 3). Make sure that it’s properly

adjusted and that the linkage operates smoothly.

Fluid leak diagnosis

6 Most fluid legks are easy to locate visually. Repair usually consists of

replacing

a seal or gasket.

If a leak is difficult to find, the following proce-

dure may help.

7 Identify the fluid. Make sure it’s transmission fluid and not engine oil or

brake fluid (automatic transmission fluid is a deep red color).

8 Try to pinpoint the source of the leak. Drive the vehicle several milesA;,_

then park it over a large sheet of cardboard. After a minute or two, you

should be able to locate the leak by determining the source of the fluid drip-

ping onto the cardboard

9 Make a careful visual inspection of the suspected component and the

area immediately around it. Pay particular attention to gasket mating sur-

faces. A mirror is often helpful for finding leaks in areas that are hard to

see.

10 If the leak still cannot be found, clean the suspected area thoroughly

with a degreaser or solvent, then dry it.

11 Drive the vehicle for several miles at normal operating temperature

and varying speeds. After driving the vehicle, visually inspect the sus-

pected component again.

12 Once the leak has been located, the cause must be determined be-

fore it can be properly repaired. If a gasket is replaced but the sealing

flange is bent, the new gasket will not stop the leak. The bent flange must

be straightened.

13

Before attempting to repair a leak, check to make sure that the follow-

ing conditions are corrected or they may cause another leak.

Note;

Some

of the following conditions cannot be fixed without high&specialized tools

and expertise, Such problems must be referred to a transmission repair

shop or a dealer service department.

Gasket leaks

14 Check the pan periodically. Make sure the bolts are tight, no bolts are

missing, the gasket is in good condition and the pan is flat (dents in the pan

may indicate damage to the vafve body inside).

15 If the pan gasket is leaking, the fluid level or the fluid pressure may be

too high, the vent may be plugged, the pan bolts may be too tight, the pan

sealing flange may be warped, the sealing surface of the transmission

housing may be damaged, the gasket may be damaged or the transmis-

sion casting may be cracked or porous, If sealant instead otgasket materi:-

al has been used to form a seal between the pan and the transmission

housing, it may be the wrong sealant.

Seal leaks

16 If a transmission

seal

is leaking, the fluid level or pressure may be too

high, the vent may be plugged, the seal bore may be damaged, the seal

itself may be damaged or improperly installed, the surface of the shaft pro-

truding through the seal~may be damaged or a loose bearing may be caus-

ing excessive shaft movement.

17

Make sure the dipstick tube seal is in good condition and the tube is

properly seated. Periodically check the area around the speedometer

gear or sensor for leakage. If transmission fluid is evident, check the O-

ring for damage.

Case leaks

18 If the case~itself appears to be leaking, the casting is porous and will

have to be repaired or replaced.

19 &lake sure the oil cooler hose fittings are tight and in good condition.

Fluid comes out vent pipe or fill tube

20 If this condition occurs, the transmission is overfilled, there is coolant

in the fluid, the case is porous, the dipstick is incorrect, the vent is plugged

or the drain-back holes are plugged.

3 Shift linkage - check and adjustment

Refer to illustrations 3. I, 3.3. 3.8, 3.9 and 3.10

1983 through 1986 models

1 The control rod is adjusted where it connects to the control arm (see

illustration).

2 Raise the front of the vehicle and support it securely on jackstands.

Loosen the adjusting locknut on the control rod-to-control arm joint.

Loading...

Loading...