6-29

Chapter 6 INSPECTION AND REPAIR OF BASIC ENGINE

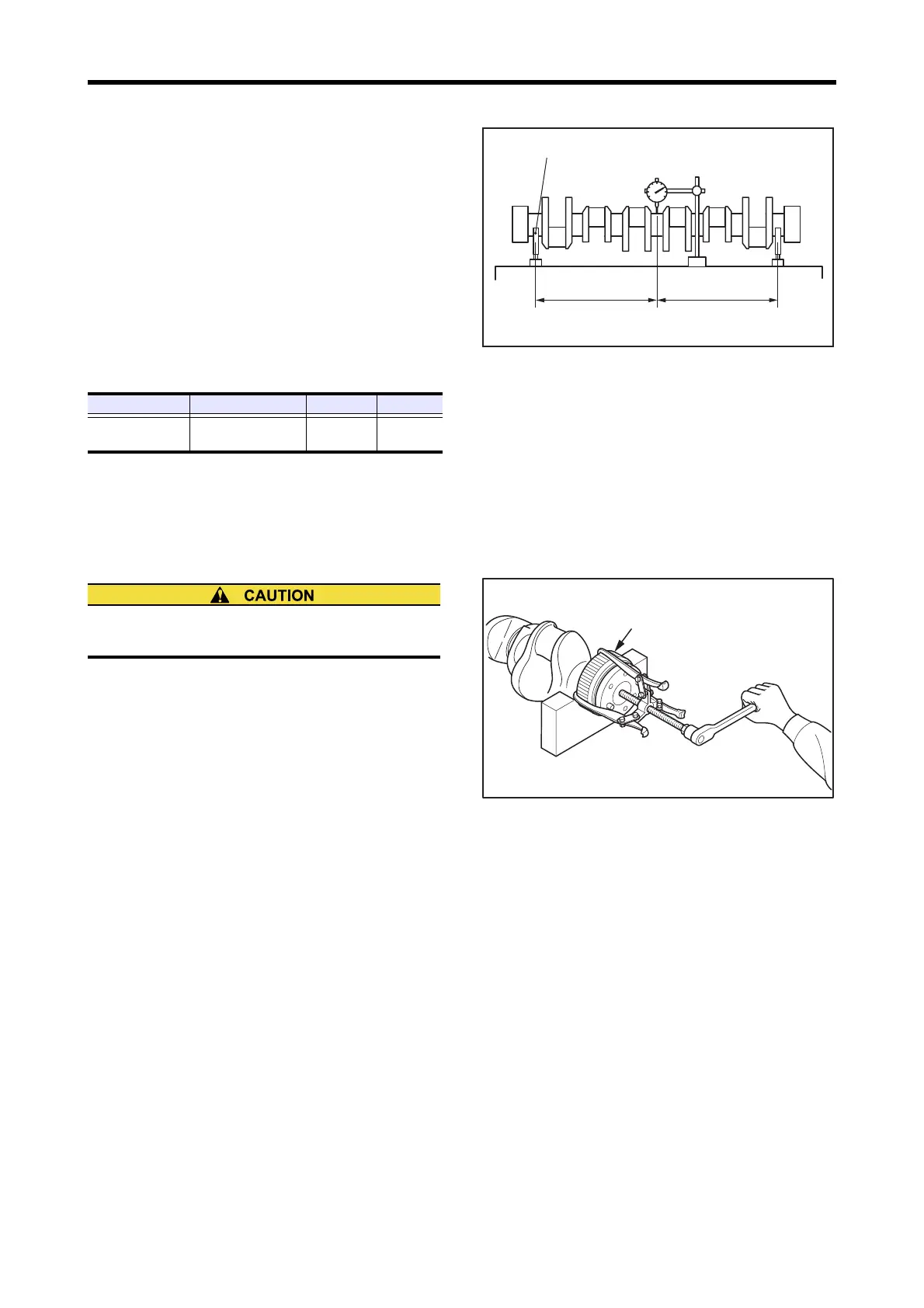

5.7 Crankshaft Runout - Measure

Support the crankshaft at front and rear main journals with

V-blocks, and measure the crankshaft runout at the center

main journal with dial gauge. If the runout deviates slightly

from the standard, correct the crankshaft by grinding. If the

value exceeds the standard considerably, straighten the

crankshaft with pressing machine.

If the value exceeds the limit, replace the crankshaft with a

new one.

If the crankshaft is repaired by grinding or pressing, inspect

the crankshaft for cracks and other harmful damage with

magnetic particle inspection.

Crankshaft Runout - Measure

5.8 Crankshaft Gear - Inspect

If there is any defect on the crankshaft gear teeth, such as

flaking, wear, or local contact, replace the crankshaft gear

with a new one.

5.9 Crankshaft Gear - Replace

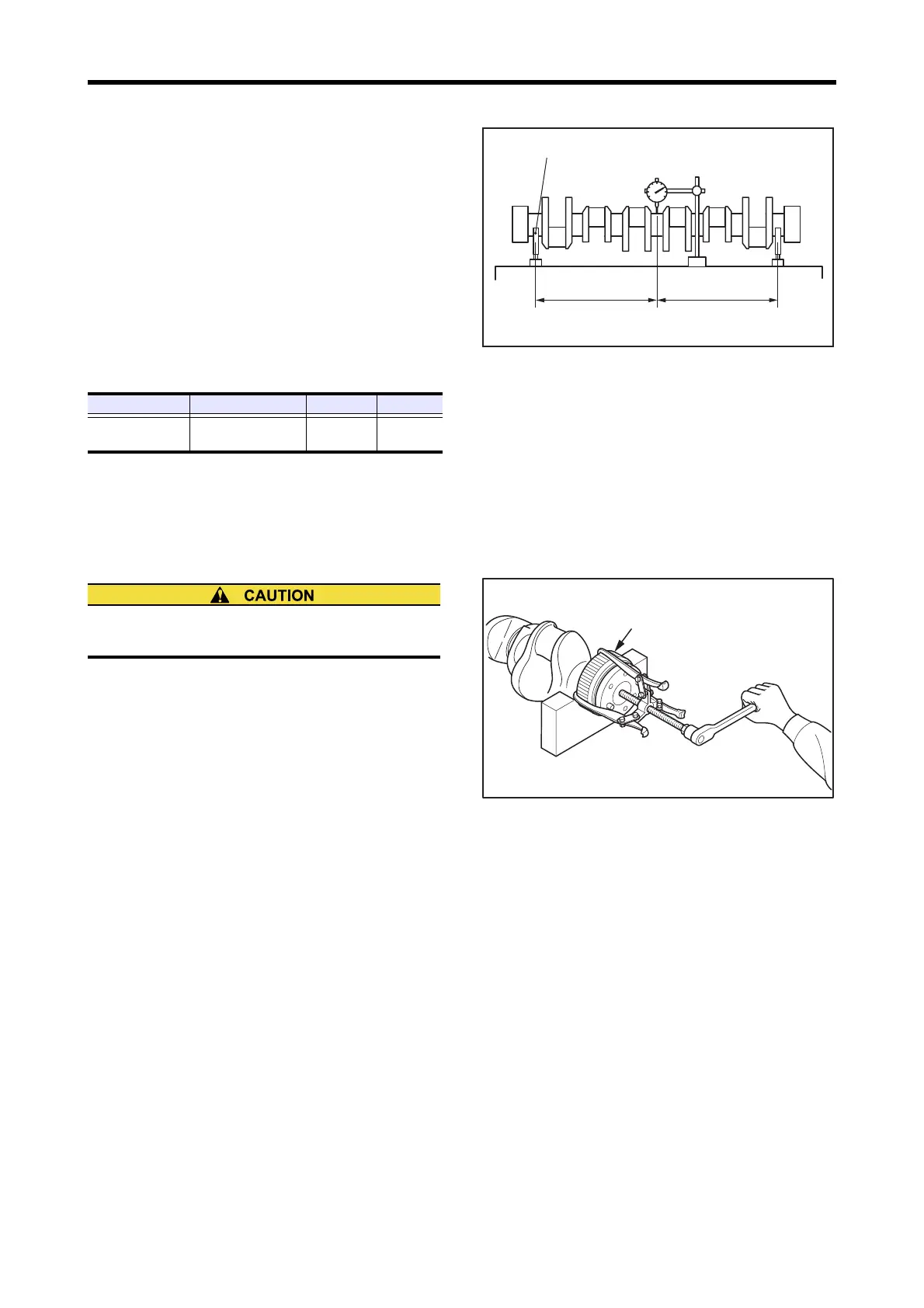

5.9.1 Crankshaft Gear - Remove

Using a gear puller, remove the gear from crankshaft.

Note: When removing the crankshaft gear by heating, the

heating temperature is 180°C [356°F] or less.

Crankshaft Gear - Remove

Item Standard value Limit value Remarks

Crankshaft runout

0.04 mm

[0.0016 in.] or less

0.10 mm

[0.0039 in.]

TIR

Surface plateSurface plate

1/2

1/2

V-block

Use protective gloves when you touch hot parts.

Handling with bear hands could result in burns.

Crankshaft gear

Loading...

Loading...