6-30

Chapter 6 INSPECTION AND REPAIR OF BASIC ENGINE

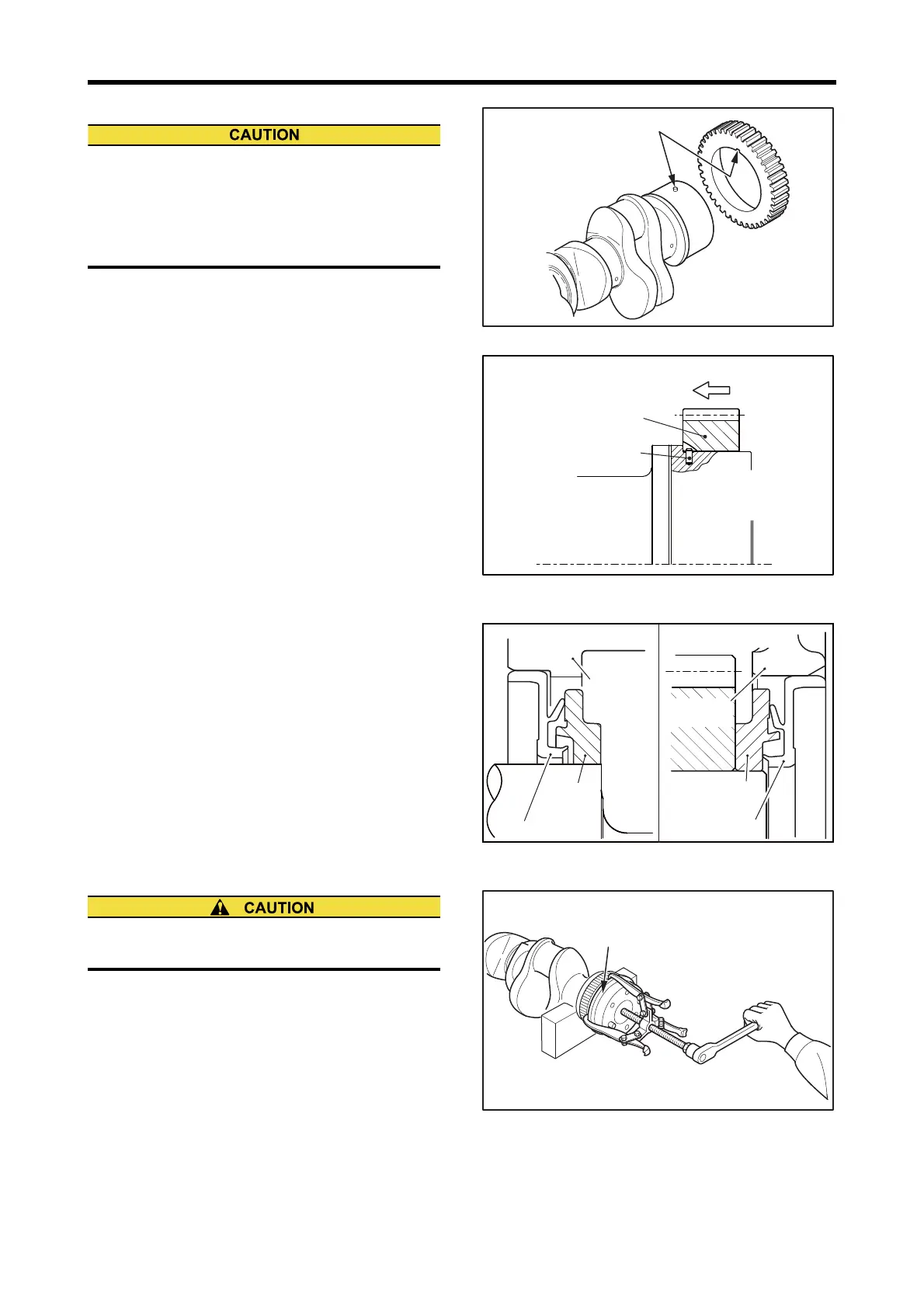

5.9.2 Crankshaft Gear - Install

(1) Measure the outside diameter of crankshaft and inside

diameter of crankshaft gear, and check the interference.

(2) Heat the crankshaft gear evenly to the specified temper-

ature. After checking gear direction and position, install

the crankshaft gear.

Crankshaft Gear - Install

Crankshaft Gear Installation Direction

5.10 Oil Seal Slinger - Inspect

If any defect such as dent, damage, wear and looseness that

can lead to oil leakage is found, replace the oil seal slinger

with a new one.

Oil Seal Slinger - Inspect

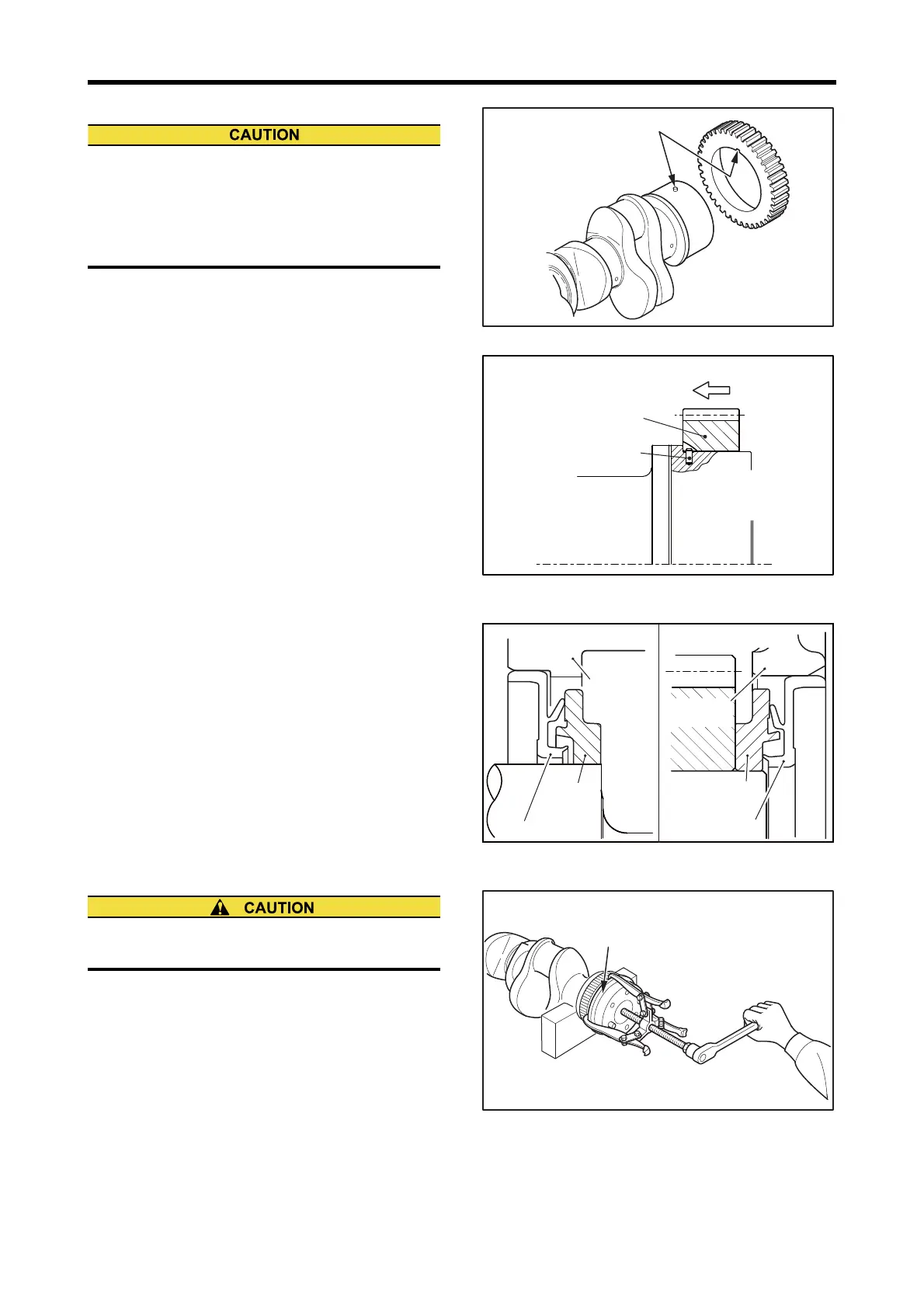

5.11 Oil Seal Slinger - Replace

5.11.1 Oil Seal Slinger - Remove

Using a gear puller, pull out the oil seal slinger from crank-

shaft.

Note: When removing the oil seal slinger by heating, the

heating temperature is 100°C [212°F] or less.

Oil Seal Slinger - Remove

(a) Check the correct installing direction and position

of crankshaft gear.

(b) To shrinkage-fit the crankshaft gear to crankshaft,

heat the crankshaft gear evenly to the specified

temperature.

Aligning position

Fitting direction

Crankshaft gear

Dowel pin

Interference standard

value: 0.106 to 0.171 mm

[0.0042 to 0.0067 in.]

Temperature for shrink fit:

180 °C [356 °F] or less

Oil seal slinger

Oil seal slinger

Oil seal

Oil seal

Oil seal slinger

Front cover

Front

Rear

Timing gear

case

Use protective gloves when you touch hot parts.

Handling with bear hands could result in burns.

Oil seal slinger

Loading...

Loading...