9-14

Chapter 9 LUBRICATION SYSTEM

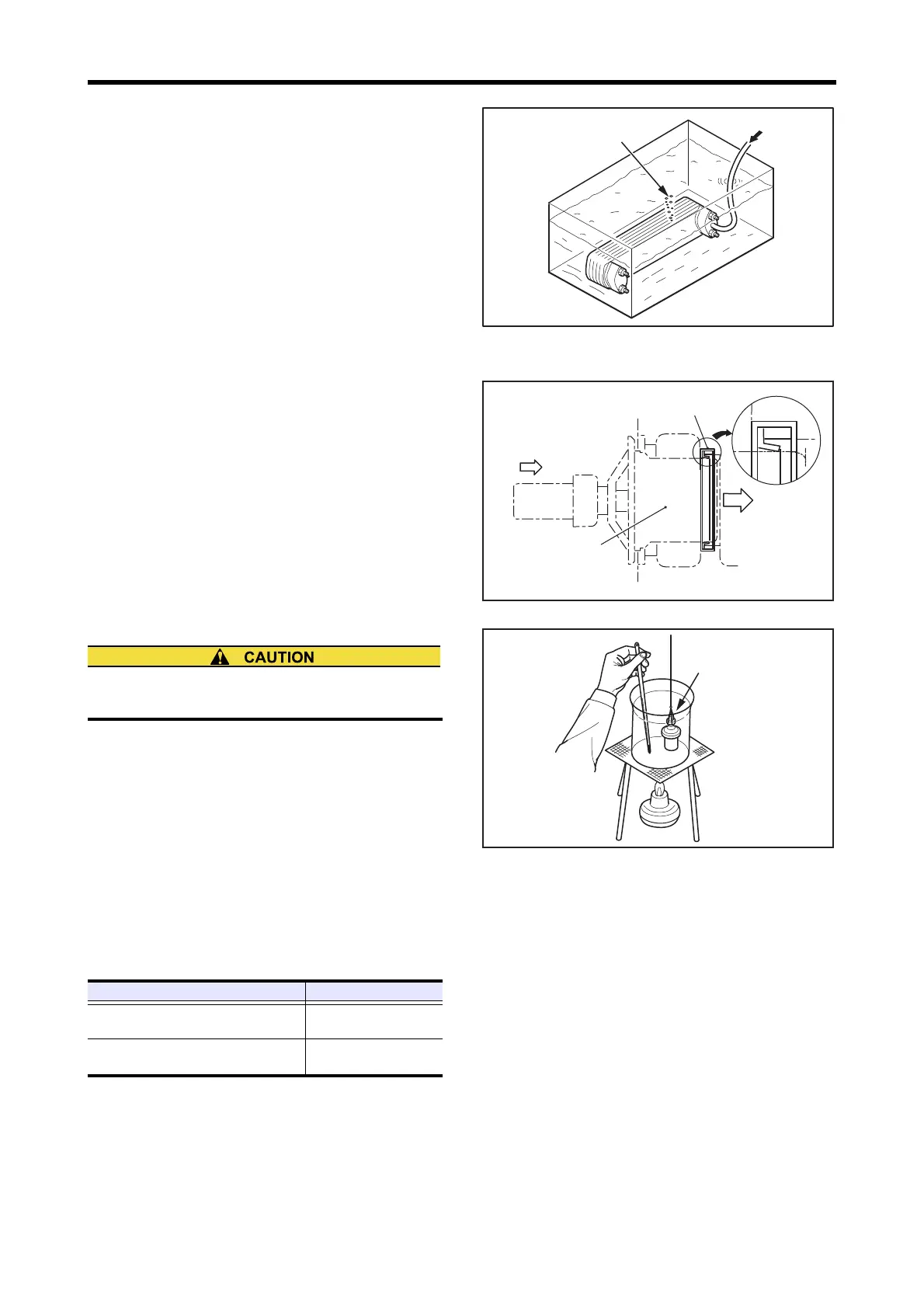

2.7.1 Oil Cooler - Inspect

Check the oil passages of element for flaws or cracks by

applying compressed air of 1.5 MPa {15 kgf/cm

2

} [217 psi].

If any leakage or damage is found, replace the element with

a new one.

Oil Cooler - Inspect

2.8 Oil Thermostat - Inspect

2.8.1 Oil Thermostat Seal - Inspect

(1) Inspect the oil thermostat seal for deterioration and

cracks. If defects are found, replace the seal with a new

one.

(2) Refer to the illustration for correct orientation of seal

installation.

Oil Thermostat Seal - Install

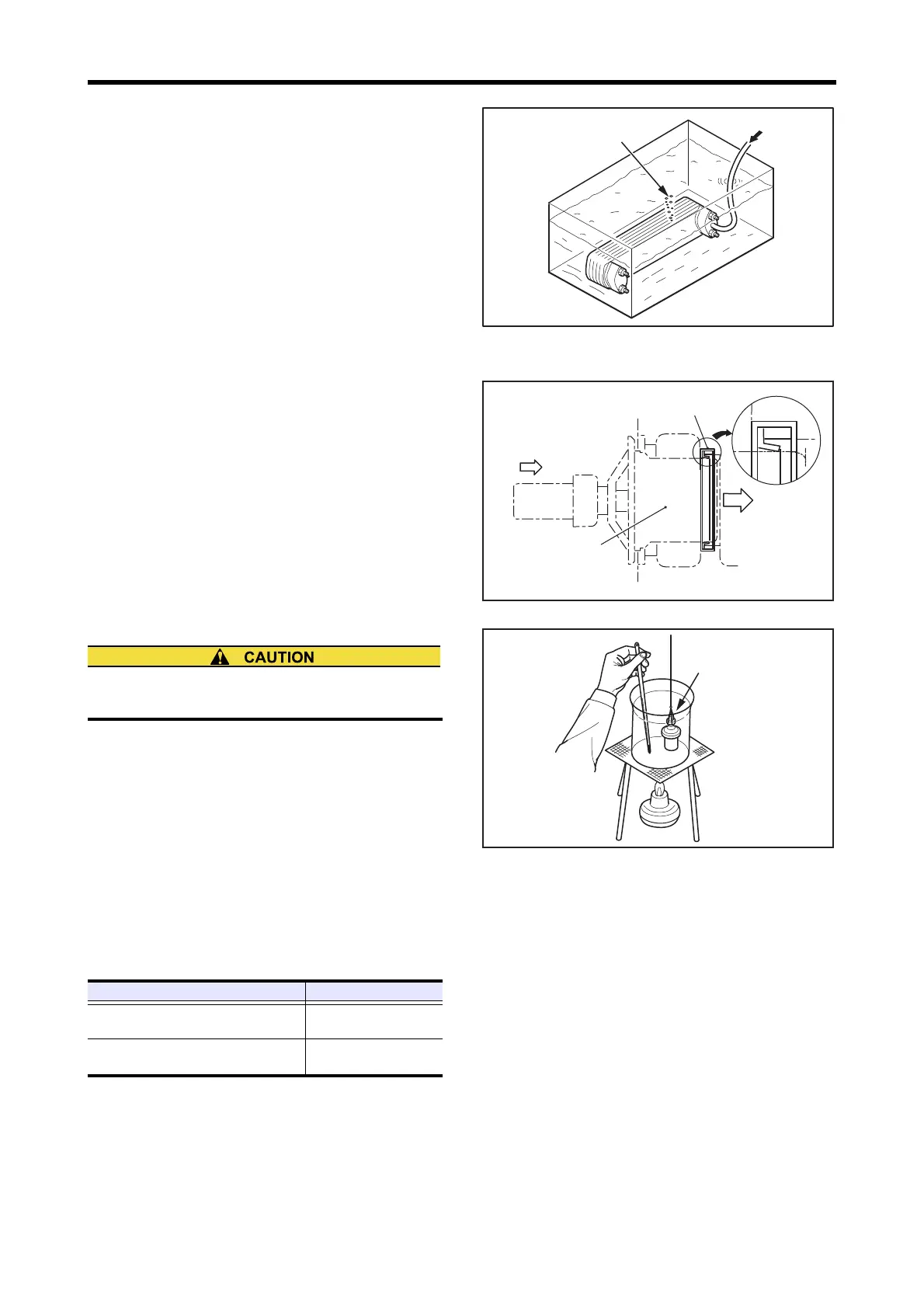

2.8.2 Oil Thermostat Operation - Inspect

(1) Put the oil thermostat fully into water in a container.

(2) Heat the water while measuring water temperature.

Record the temperature at which valve start to open,

and at which valve lift becomes to the standard value.

Replace the thermostat if a deviation from the standard

temperature is unusual.

Note:(a) Stir the water to maintain uniform temperature dur-

ing the test.

(b) At assembling, be sure to check the valve opening

temperature marked on the side of thermostat valve.

Oil Thermostat Operation - Inspect

2.9 Oil Cooler and Oil Thermostat - Assemble

To assemble, follow the disassembly sequence in reverse.

Thoroughly clean oil passages with wash oil, and dry the

cleaned parts with compressed air.

Air

Leak, flaw, crack

Mounting direction

Thermostat

Thermostat seal

Be very careful with hot water and flames.

Or, you may get burned or cause a fire.

Item Standard value

Valve opening temperature

80 to 84°C

[176 to 183.2°F]

Temperature at which valve lift becomes

11 mm [0.43 in.] or more

95°C

[203°F]

Water (stir with a stick)

Loading...

Loading...