9-17

Chapter 9 LUBRICATION SYSTEM

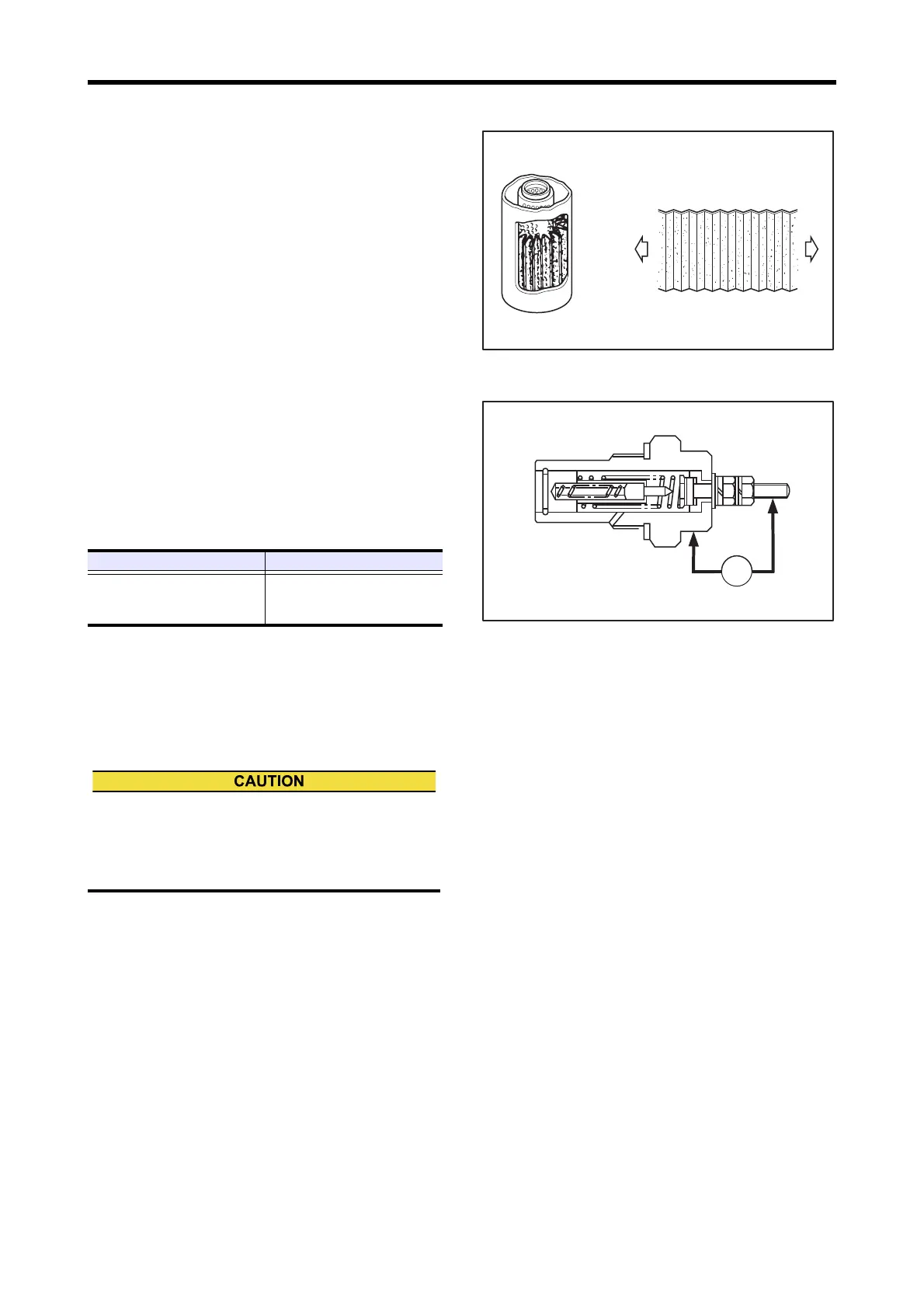

2.11 Oil Filter - Inspect

When replacing the oil filter, sample the oil (500 ml [0.13

U.S. gal]) and check for metal and other particles. If metal

or other particles are found, cut and unfold the element, and

inspect the color and shape of metal particles trapped in ele-

ment to identify the cause.

Oil Filter - Inspect

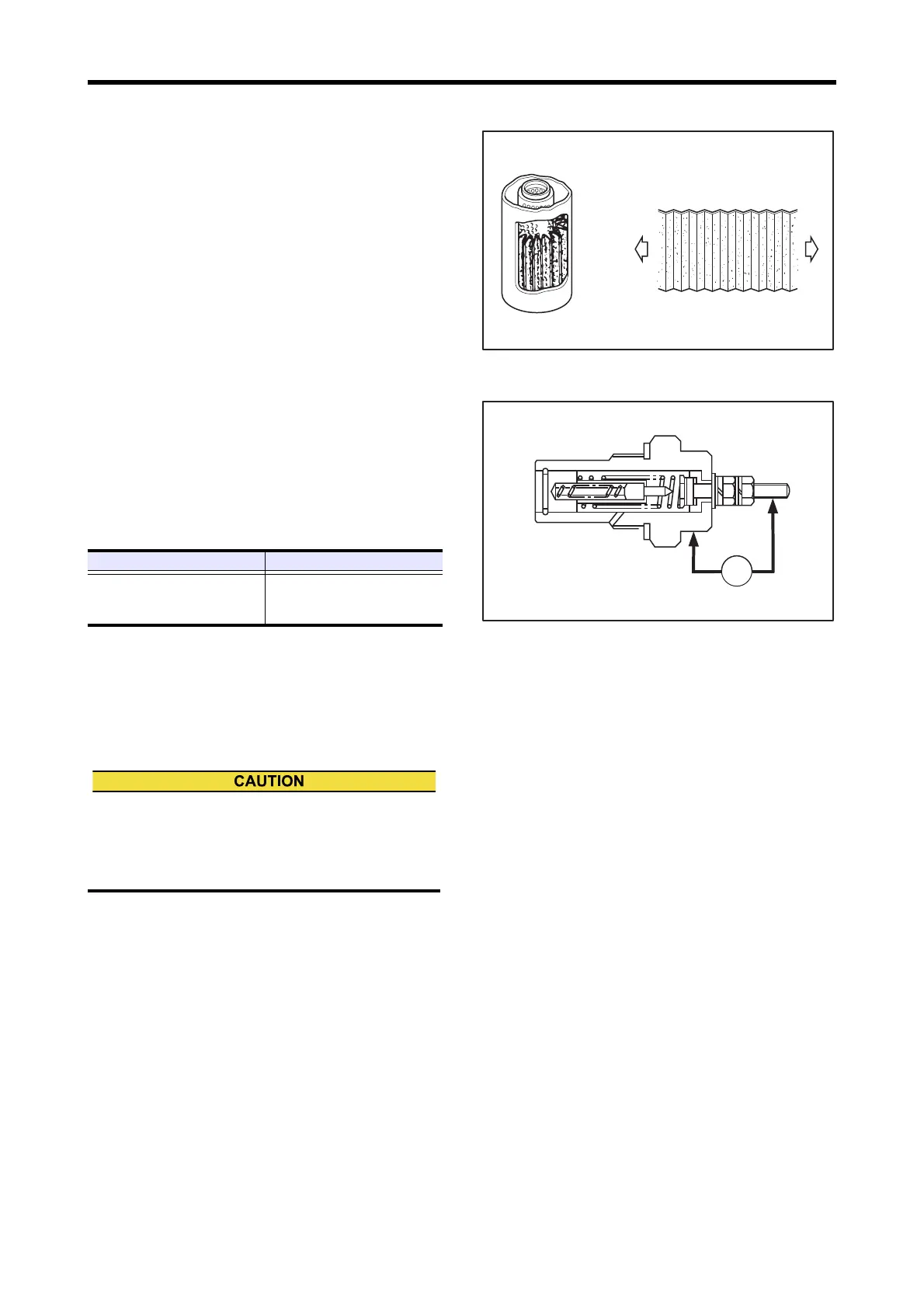

2.12 Oil Filter Alarm - Inspect

(1) Use a tester to check the alarm for insulation and conti-

nuity. If the alarm is defective, disassemble and repair.

If the bakelite or rubber insulations are deteriorated or

damaged, replace the alarm.

(2) If the filter alarm activation pressure is out of the stan-

dard, replace the alarm with a new one.

Oil Filter Alarm - Inspect

2.13 Oil Filter - Assemble

To assemble, follow the disassembly sequence in reverse.

Thoroughly clean oil passages with wash oil, and dry the

cleaned parts with compressed air.

2.14 Oil Filter Cartridge - Install

(1) Remove dust and contamination on oil filter cartridge

mating face.

(2) Apply clean engine oil on oil filter gasket.

(3) After the oil filter gasket contacts with base surface,

tighten the cartridge by 3/4 to 1 turn by hand.

(4) Start the engine, and make sure that there is no fuel

leaks.

Item Standard value

Oil filter alarm

differential pressure for

activation of alarm

0.15 to 0.18 MPa

{1.5 to 1.8 kgf/cm

2

}

[217.6 to 261.1 psi]

(a) When installing oil filter cartridge, tighten it by

hand. (Do not use filter wrench.)

(b) Be careful not to dent or damage the surface of

cartridge.

Loading...

Loading...