7-17

Chapter 7 ASSEMBLY OF BASIC ENGINE

2.14 Piston Protrusion - Measure

Measure the protrusion of each piston, following the

instructions below. If the value exceeds the limit, inspect the

clearances between various parts involved.

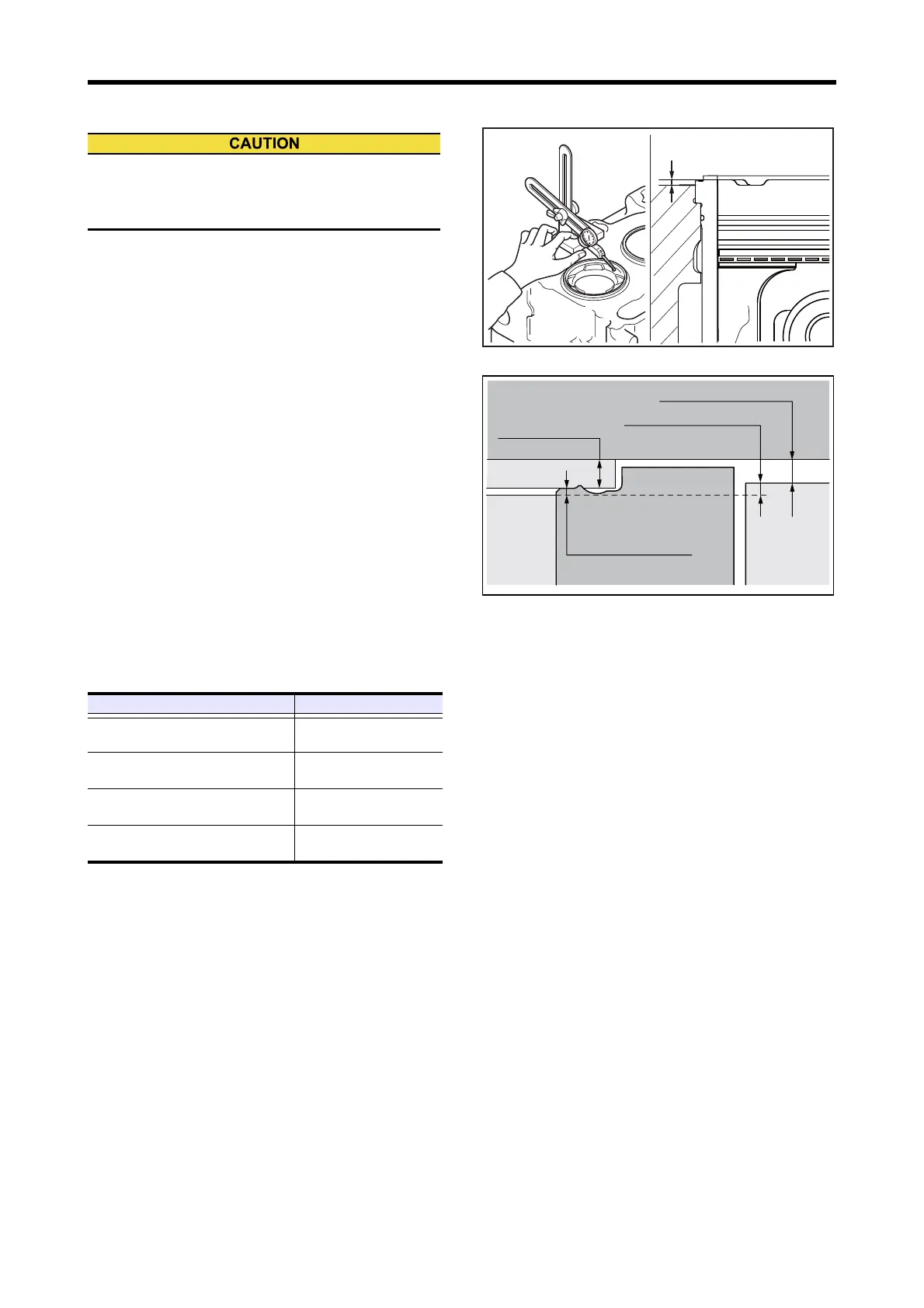

(1) Move the piston to the top dead center.

(2) Apply the dial gauge probe to the top face of crankcase,

and adjust the dial gauge to zero.

(3) Move the dial gauge to the top face of piston, measure

the maximum protrusion by turning the crankshaft near

top dead center.

Note: The crankshaft position that indicates the maximum

protrusion is defined as the correct top dead center.

(4) Measure the protrusion at four places on the piston top

face, and calculate the mean value.

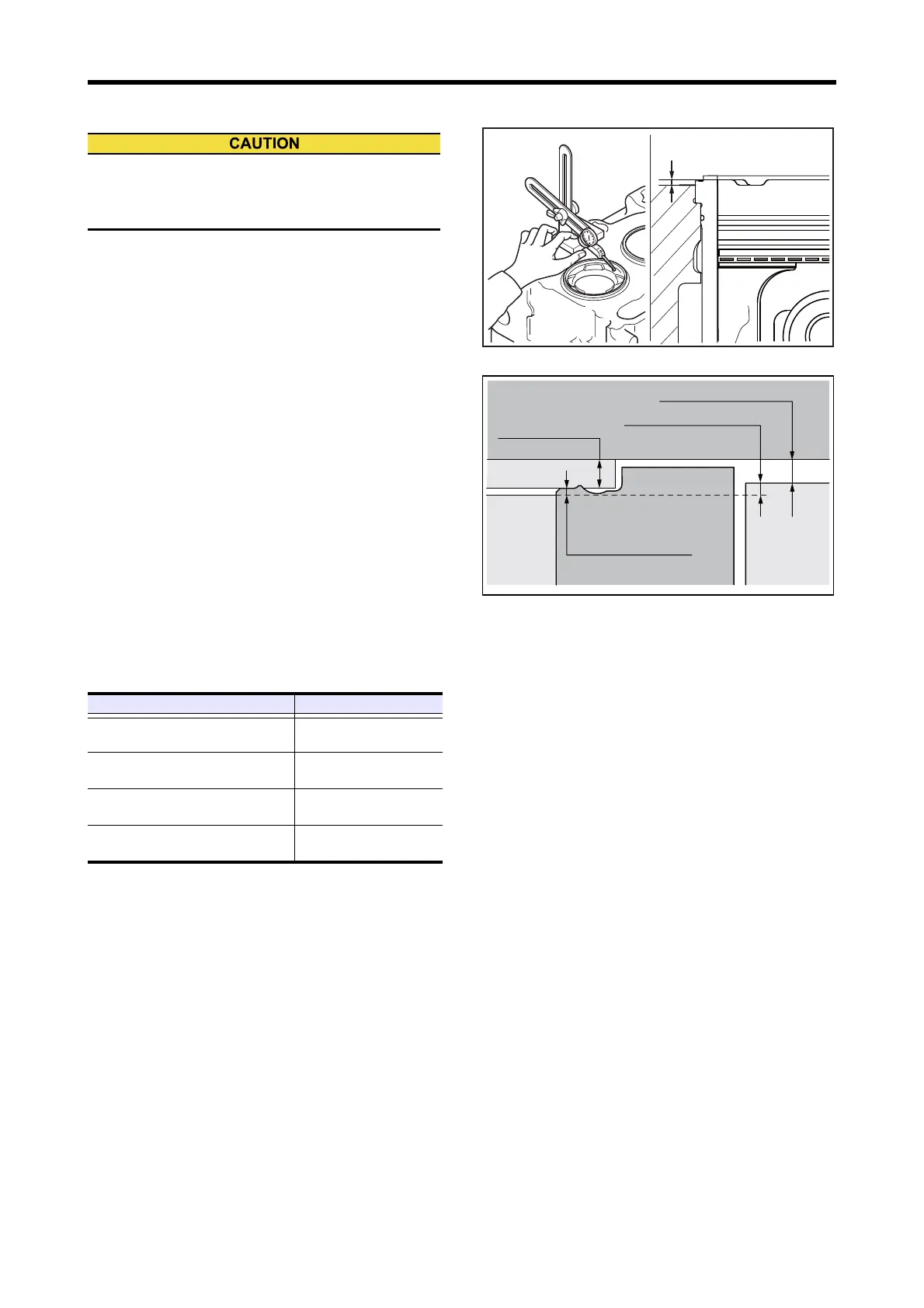

Note: The top clearance (clearance between the piston top

and cylinder head) can be calculated by the piston pro-

trusion, cylinder liner flange protrusion and cylinder

head gasket thickness.

Top clearance = Cylinder head gasket thickness + Cyl-

inder liner flange protrusion - Piston protrusion

Piston Protrusion - Measure

Top clearance

Piston protrusion must always meet the standard, as

the amount of protrusion not only influences engine

performance, but it also prevents valve from stamping.

Item Standard value

Piston protrusion

0.04 to 0.64 mm

[0,0016 to 0.0252 in.]

Cylinder liner flange protrusion

0.11 to 0.20 mm

[0.0043 to 0.0079 in.]

Thickness of cylinder head gasket

1.77 to 1.83 mm

[0.0697 to 0.0720 in.]

Top clearance

1.24 to 1.99 mm

[0.0488 to 0.0783 in.]

Cylinder headCylinder head

Cylinder linerCylinder liner

Cylinder liner

Cylinder liner flange

Cylinder liner flange

protrusionprotrusion

Cylinder liner flange

protrusion

CrankcaseCrankcaseCrankcase

Piston protrusion

Piston protrusionPiston protrusion

Top clearance

Top clearance

Top clearance

Cylinder head gasket

Cylinder head gasket

thickness thickness

Cylinder head gasket

thickness

Cylinder head

PistonPiston

Piston

Loading...

Loading...