49Service Manual – SC6000 20 - Wheel System, Traction

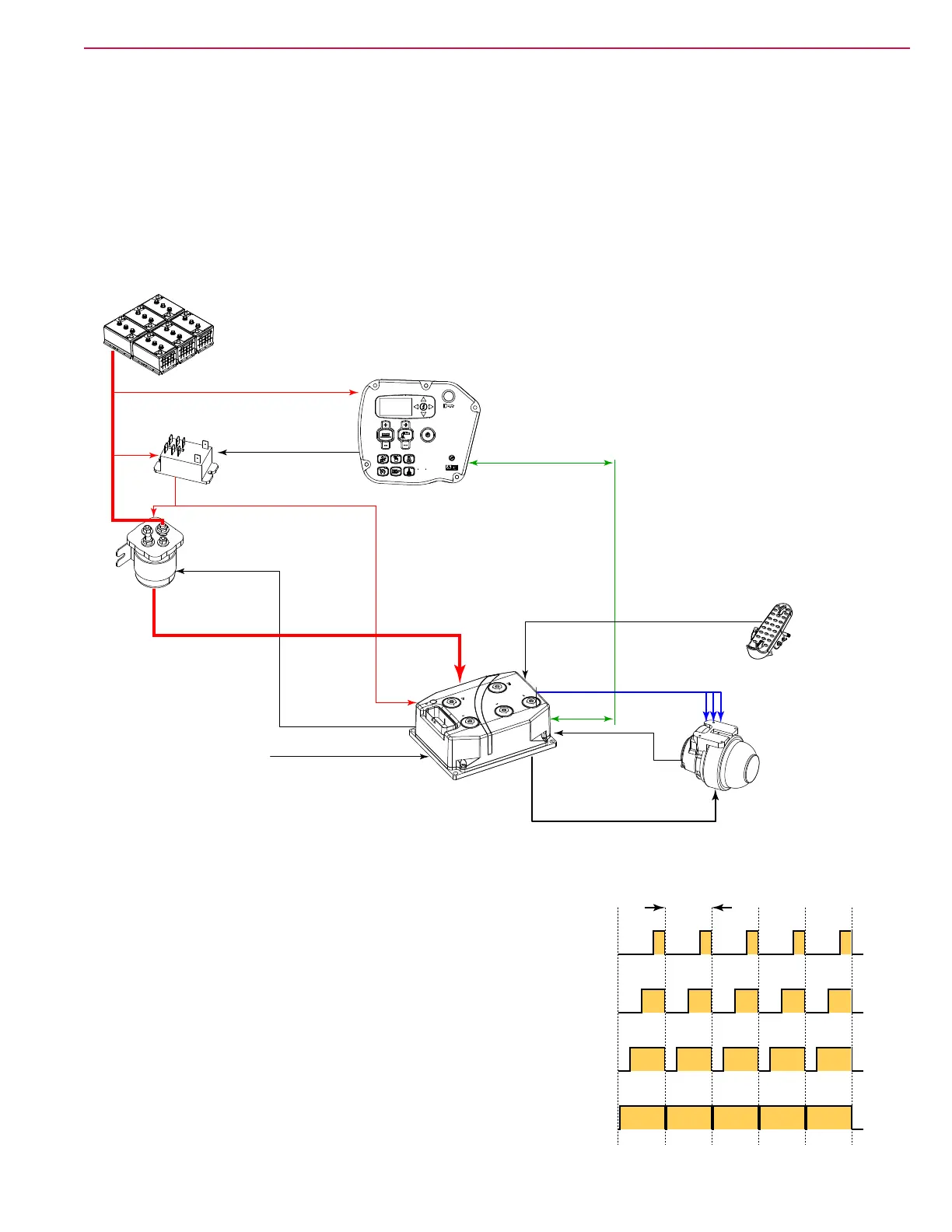

Drive Controller

The KSI relay provides logic power to the drive controller. When the main machine controller is not

energizing the KSI relay, the drive controller has no power. However, the drive controller has control of its

own power relay (K3). This provides separate high-current power output for the motor control. The drive

controller also monitors the E-stop switch and seat switch, so that either one can disable the drive output.

Output is disabled if either the seat switch or E-stop is open. The drive controller also receives many of its

operating parameters from the main machine controller.

The motor contains an electromechanical brake, that releases only when power is present. The drive

controller releases the brake when the wheel motor is commanded to turn.

E2 Main Control Board

E4 Wheel Drive Controller

K1 KSI Relay

Control

K3 Relay

Control

Power

CAN Bus

3Ø PWM

Temp/Pos

Feedback

Foot Pedal

Main Battery Power

Wheel Motor

E-Stop Switch

Brake

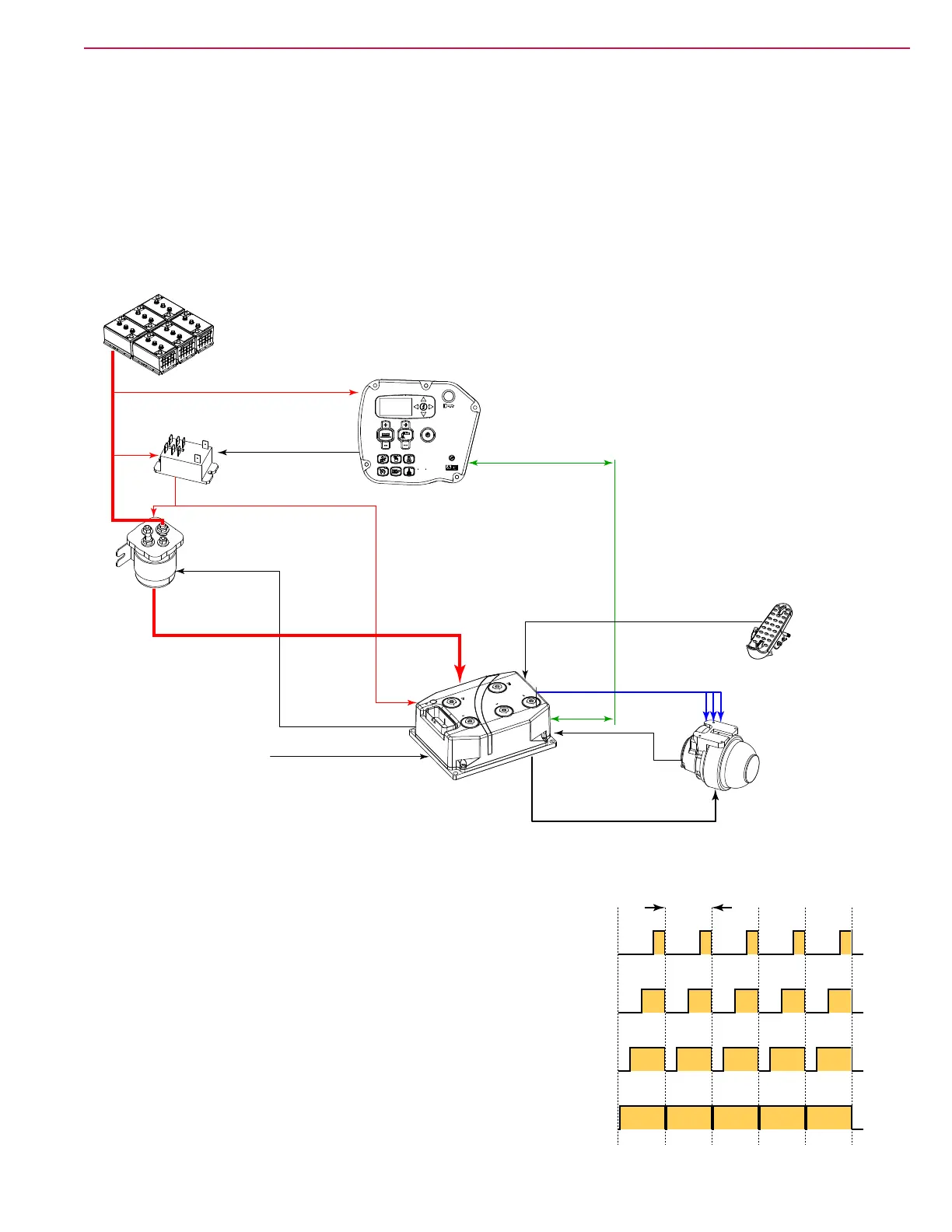

The drive motor is controlled from a Curtis 1232E drive controller, which is an AC induction motor controller

for battery operated equipment. The controller generates a square wave, 3-phase, pulse-width-modulated

output to the motor. The speed controller is designed specically for DC

motors with remote commutation. Pulse-width-modulation (PWM) is a

form of motor speed control that alters the power to a motor by rapidly

turning the power on and off. The ratio (also called “duty cycle”) between

the On and Off states determines how much power the motor receives.

The shorter the “off-time” the closer to full power the motor will receive.

This switching occurs so fast (15kHz for this controller) that the motor

simply sees it as a reduction in power (voltage) instead of the rapid on/off.

PWM is a standard motor control technique because it is easier to turn

power all the way on and all the way off, than it is to vary the magnitude

of the power. Varying the magnitude would create a lot of heat that

would need to be dissipated.

25% PWM Duty Cycle

50% PWM Duty Cycle

75% PWM Duty Cycle

100% PWM Duty Cycle

1-Cycle

(15kHz)

Loading...

Loading...