Adjustment

13 - 21

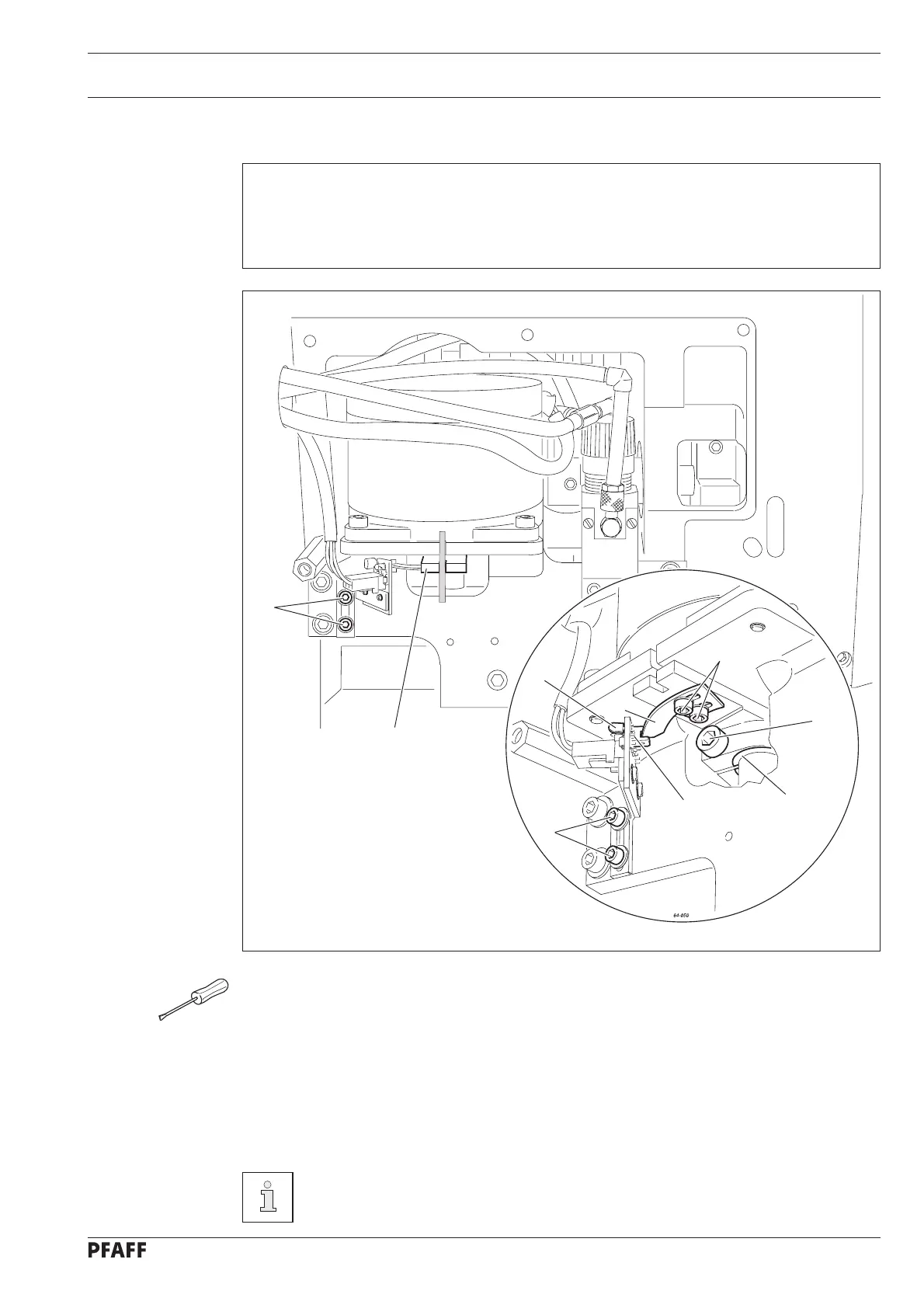

Fig. 13 - 19

4

1

3

4

5

6

7

2

8

13.21 Basic position of the button clamp drive

Requirement

1. After the machine has been switched on, it should be possible to lock lever 1 with the

needle rise gauge (2.4 mm).

2. Switch lug 5 should be positioned in the centre of the recess of the light barrier 3.

● Loosen screw 1.

● Switch on the machine.

● Adjust lever 2 in accordance with requirement 1 (lock with needle rise gauge).

● Tighten screw 1.

● Adjust light barrier 3 (screws 4) in accordance with requirement 2.

● With lever 1 locked, move the switch lug 5 (screws 6), until LED 7 lights up and then

move it back again until LED 7 has just extinguished.

● Switch off the machine and remove the needle rise gauge.

Spring clip 8 serves as an adjustment aid and should be touching lever 2. The

open side of the spring clip 8 should be in alignment with the clamp groove of

lever 2.

Loading...

Loading...