Adjustment

13 - 37

108-073

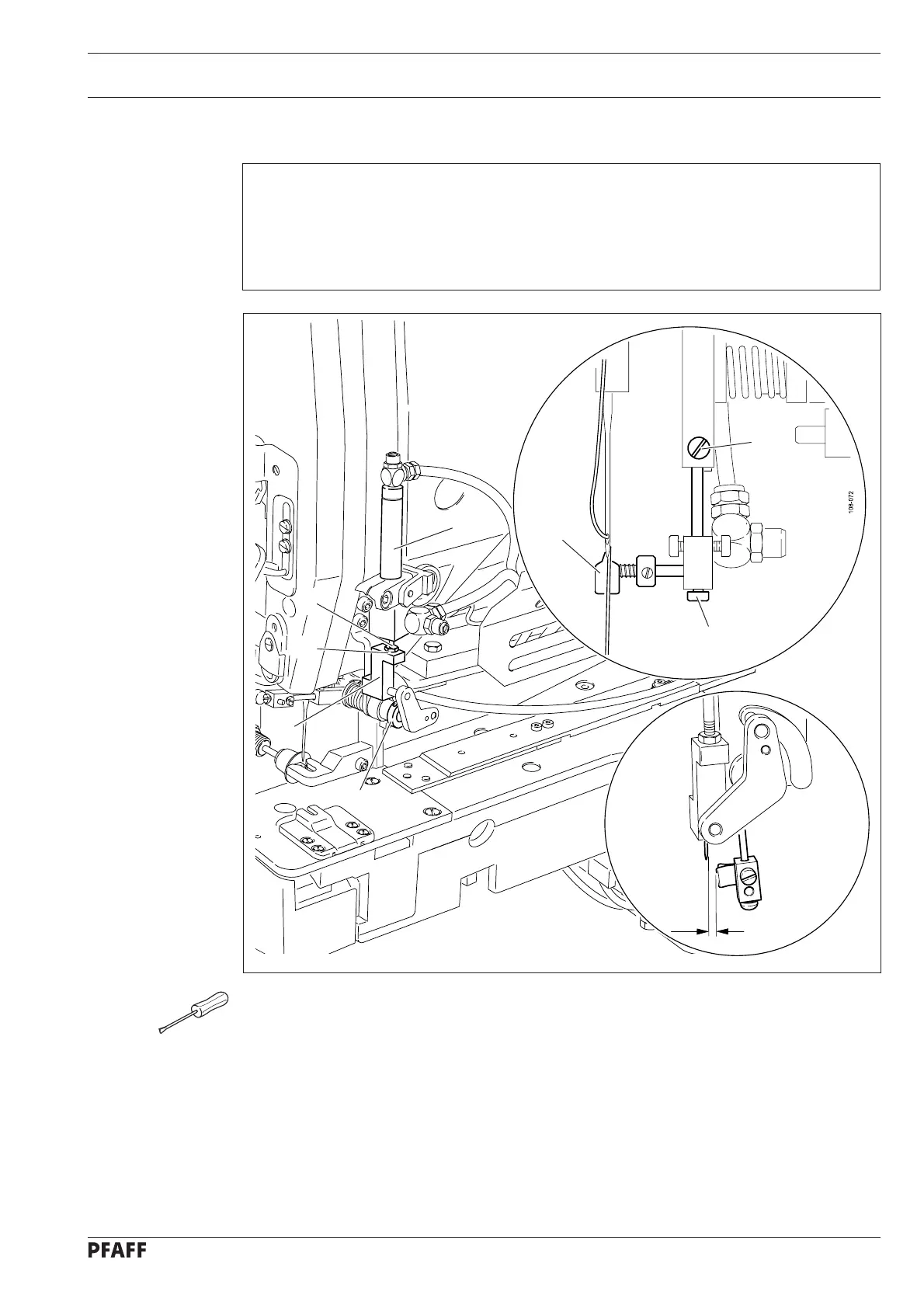

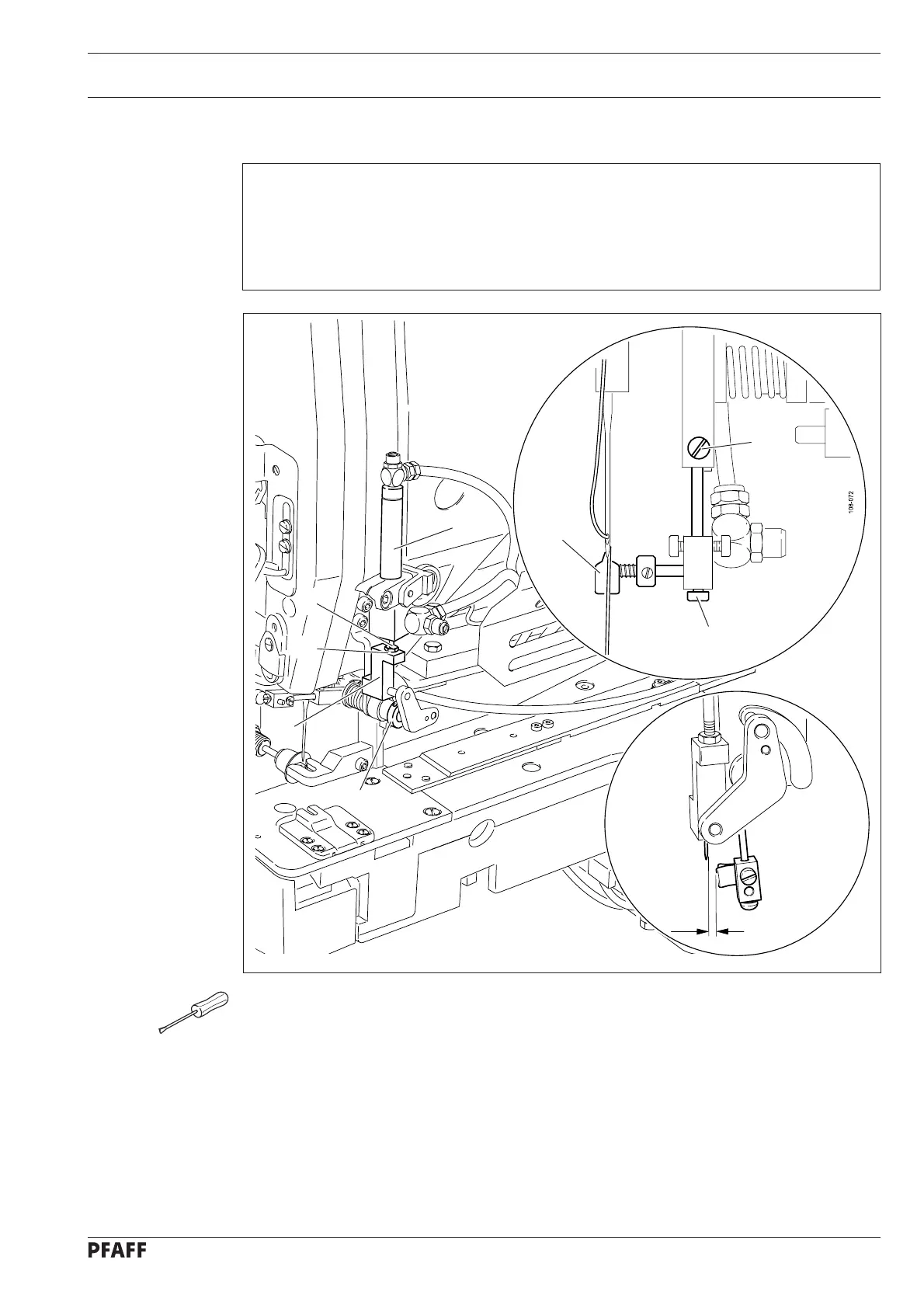

13.37 Adjusting the thread wiper (only on subclass -5/..)

Requirement

1. In cutting position, the thread wiper 1 should be centred to the needle, and with the

needle bar at t.d.c. it should swing though under the needle without contact.

2. When the cylinder 6 is extended, bearing block 7 should not collide with adjusting ring

8, and thread wiper 1 should be approx. 3 mm behind the needle.

● Connect the machine to the pneumatic system and switch it on.

● Engage thread wiper 1 using parameter "603".

● Adjust thread wiper 1 (screws 2 and 3) in accordance with requirement 1.

● Adjust piston rod 4 (nut 5) in accordance with requirement 2.

● Set parameter "403" to its maximum value.

● Check the setting during the sewing process and correct it if necessary.

● Reset parameter "403".

● Switch off the machine and disconnect it from the pneumatic system.

Fig. 13 - 32

1

2

3

7

8

6

4

5

108-132

3 mm

Loading...

Loading...