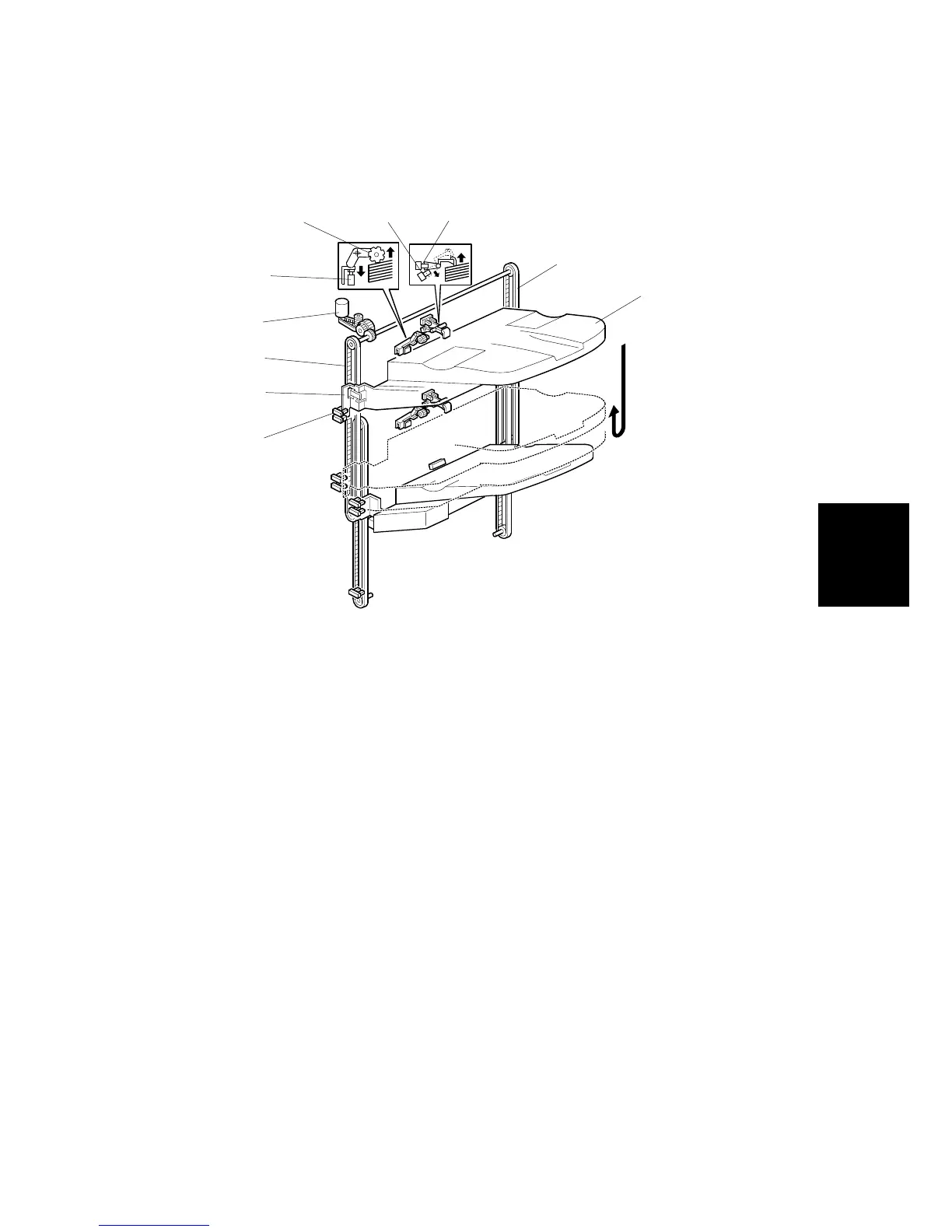

TRAY UP/DOWN MECHANISMS

SM 23 G838

Finisher

G838

4.5 TRAY UP/DOWN MECHANISMS

4.5.1 TRAY 1

Introduction

The tray 1 lift motor [A] controls the vertical position of tray 1 [B] through gears and

timing belts [C].

Normal and sort/stack modes

When the main switch is turned on, the tray is initialized at the upper position. To

do this, the tray is moved up until upper stack height sensor 1 [D] is de-actuated.

During printing, if upper stack height sensor 2 [E] is actuated, the tray 1 lift motor

lowers the tray for a specified time.

When the tray lowers during printing, the actuator [F] will pass through the tray 1

overflow sensor [G]. When the actuator drops below the sensor (to deactivate the

sensor), the machine detects that the paper stack height has exceeded a certain

limit.

The upper limit switch for tray 1 [H] prevents the drive gear from being damaged if

the upper stack height sensor 1 should fail. If the tray is raised to the tray

positioning roller [I], the switch will automatically cut the power to the tray 1 lift

motor.

B352D204.WMF

[A]

[B]

[C]

[D]

[E]

[G]

[F]

[H]

[I]

[C]

Loading...

Loading...