338 Rockwell Automation Publication 7000L-UM301F-EN-P - March 2020

Chapter 5 Component Definition and Maintenance

Fluid Conductivity

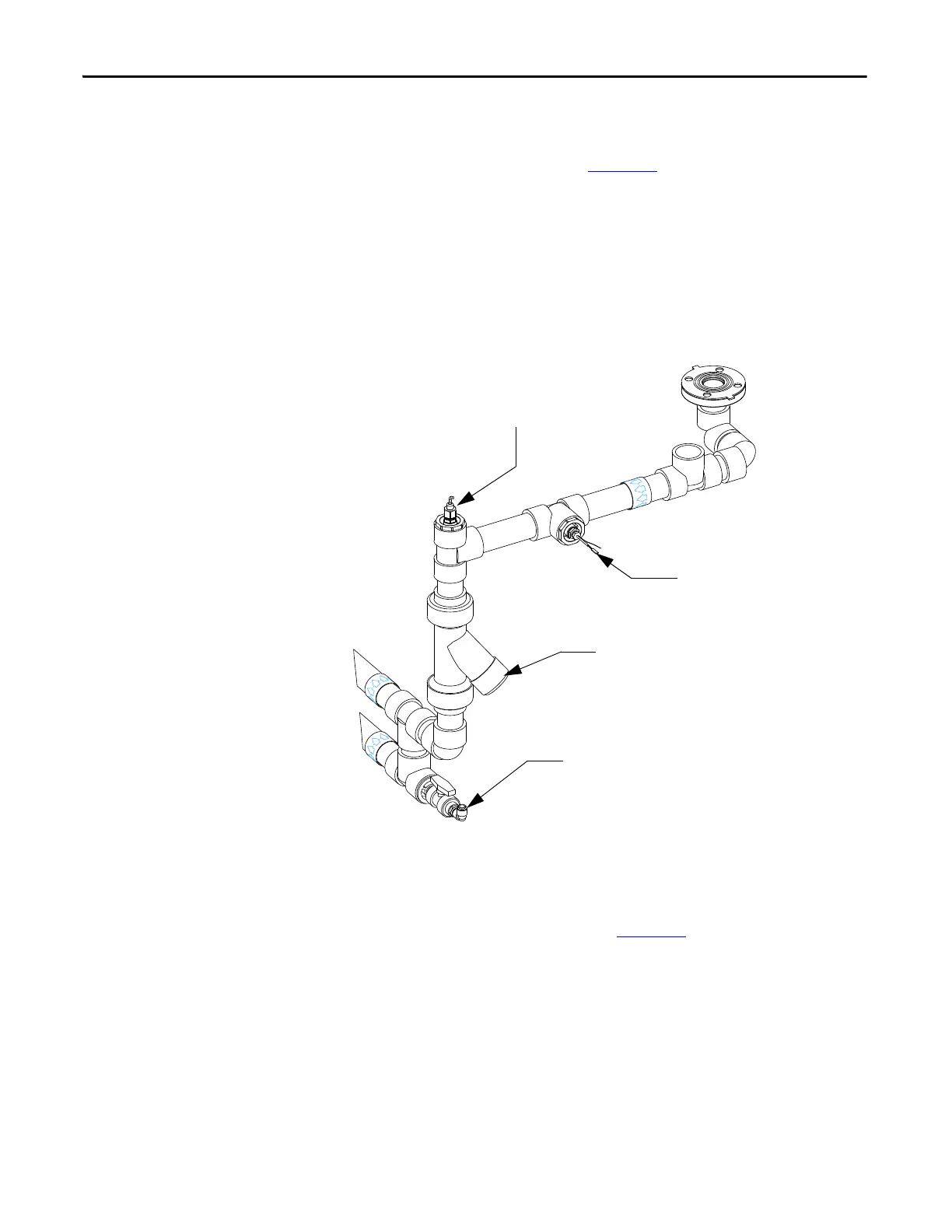

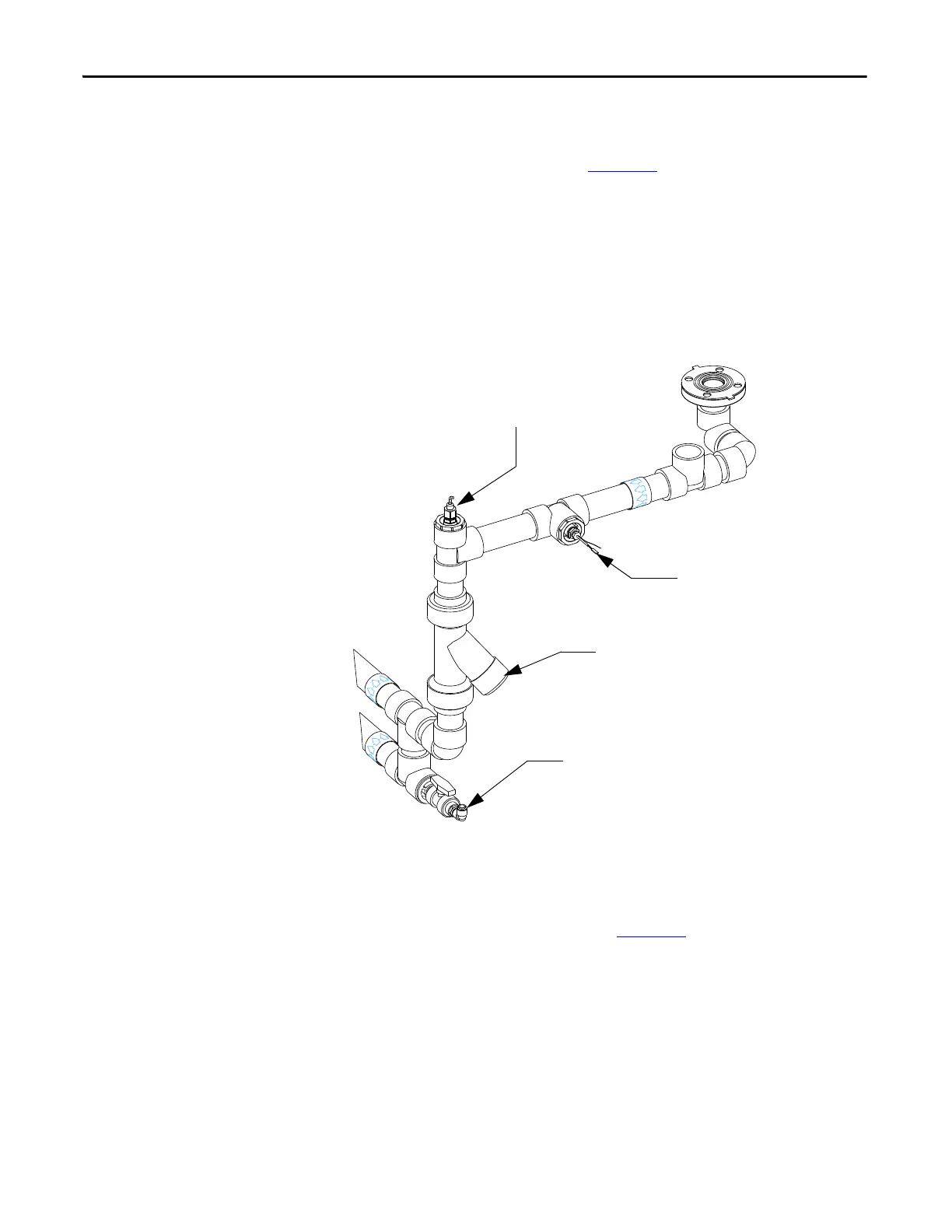

An in-line conductivity sensor (XS) (Figure 283) measures the fluid

conductivity. The sensor sends a signal to a meter mounted on the pump cabinet

door. Two conductivity switches are part of the meter. They are set at

conductivity of 1 µS/cm

3

for the annunciation warning and 2 µS/cm

3

for the trip

value.

Change the deionization cartridge when the conductivity rises to the warning

level.

Figure 283 - Temperature and Conductivity Sensors

Temperature Sensor

This temperature sensor (TS1), shown in Figure 283, triggers the drive to shut

down when the fluid temperature entering the converter cabinet is too high. This

situation could occur if the air cooling of the heat exchanger is cut off due to fan

failure, plugging of the air paths, or failure of the thermostatic valve.

The following are the temperature values for alarm and trip signal:

1. When coolant temperature is greater than 48 °C (120 °F), an alarm signal

is initiated. It can only be reset when temperature reaches 38 °C (100 °F).

Conductivity Sensor x5

Strainer STR1

V6 Fill/Drain Valve

Temperature Sensor TS1

Loading...

Loading...