4

Creating a ShopTurn Program 08/2005

4.1 Pro

ram structure

4

♥ Siemens AG, 2005. All rights reserved

4-124 SINUMERIK 840D sl Operation/Programming ShopTurn (BAT) – 08/2005 Edition

4.1 Program structure

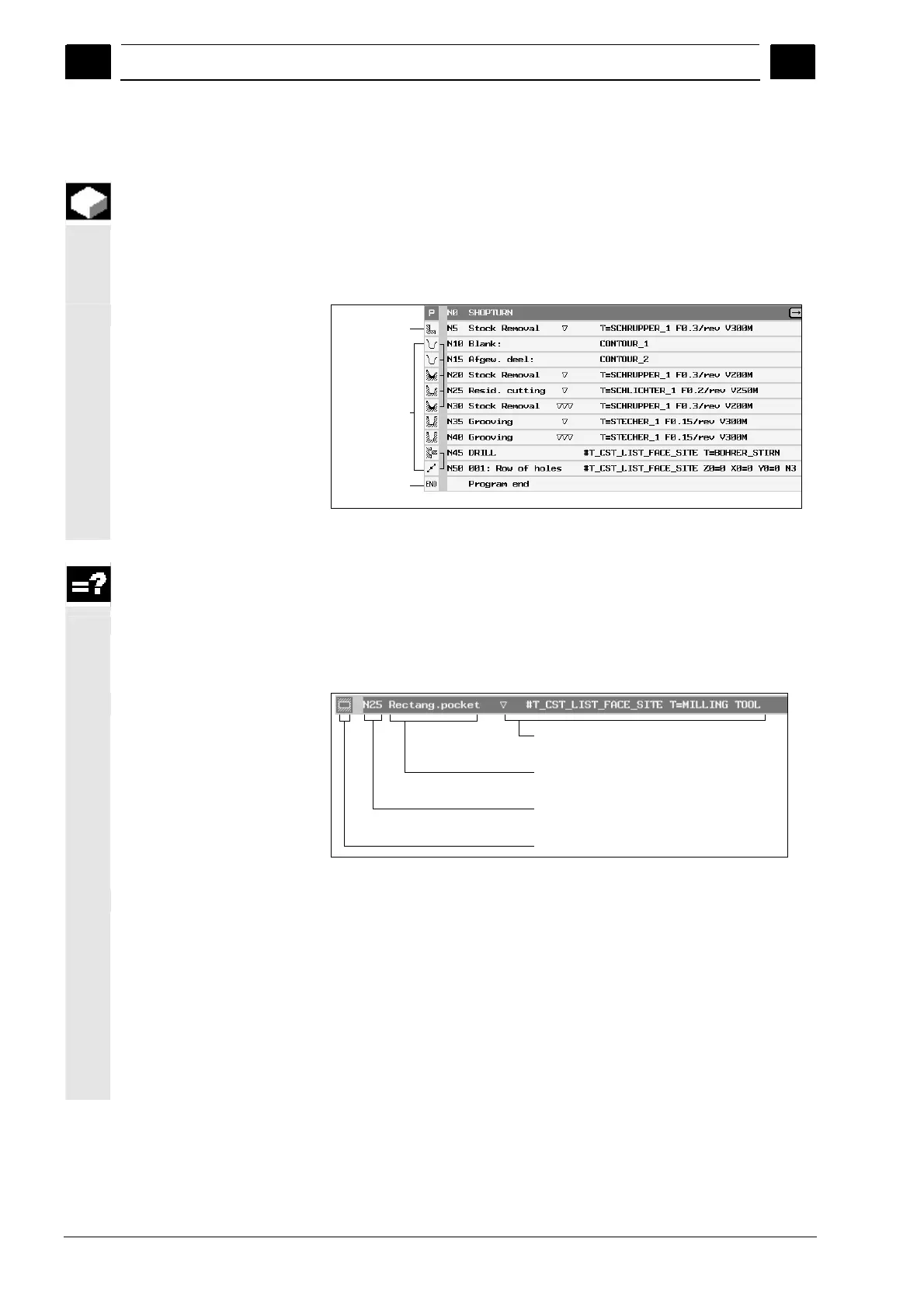

A sequential control program is divided into three sub-areas:

Program header

Program blocks

End of program

These sub-areas form a machining plan.

Program

header

Program

end

Program

blocks

Program structure

Program header

The program header contains parameters that affect the entire

program, such as blank dimensions or retraction planes.

Program blocks

You determine the individual machining steps in the program blocks.

In doing this, you specify the technology data and positions, among

other things.

Technology data and

positions

Plain text, e.g. type

of machining

Block number allocated

by control

Symbol of machining cycle

Program block

Linked program blocks

For the "Contour turning", "Contour milling", "Milling", and "Drilling"

functions, program the technology blocks and contours or positioning

blocks separately. These program blocks are automatically linked by

the controller and connected by brackets in the work plan.

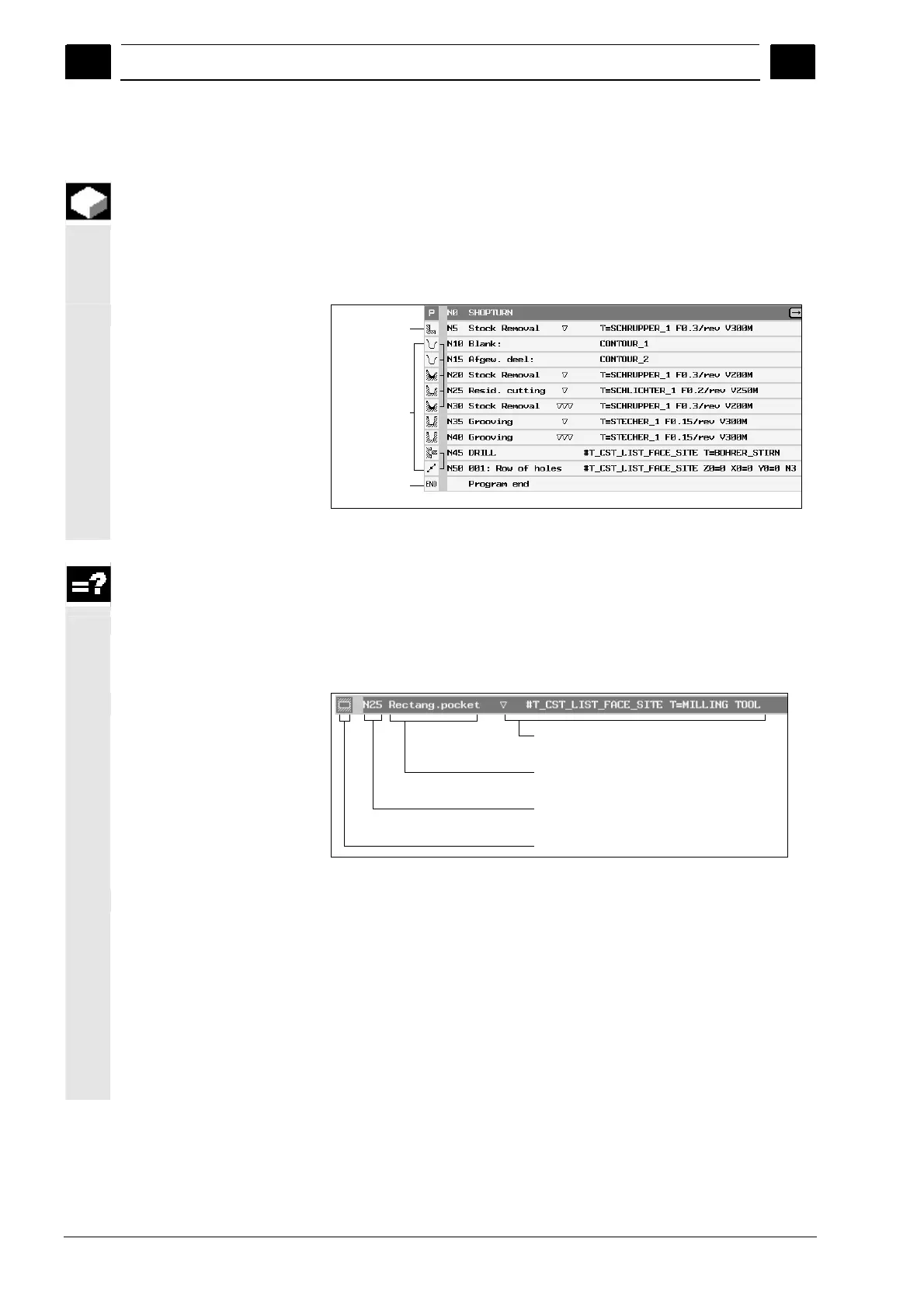

In the technology blocks, specify how and in what form the machining

should take place, e.g. centering first, and then drilling. In the

positioning blocks, determine the positions for the drilling or milling

machining, e.g. position the drill-holes in a full circle on the front

surface.

Loading...

Loading...