7-50

DSR-2000A/2000AP

7-17. Loading Motor Replacement

Outline

Replacement

Disconnecting the connector

Replacing the loading motor assembly

Reconnecting the connector

Preparation

1. Set the unit to the unthreading end status.

2. Power off the unit.

3. Remove the top panel. (Refer to Section 3-3.)

4. Remove the cassette compartment. (Refer to Section 3-4.)

Tools

. Torque screwdriver’s bit (for M1.4) : J-6325-110-A

. Torque screwdriver (for 3 kgf.cm) : J-6325-400-A

. Tweezers

Replacement

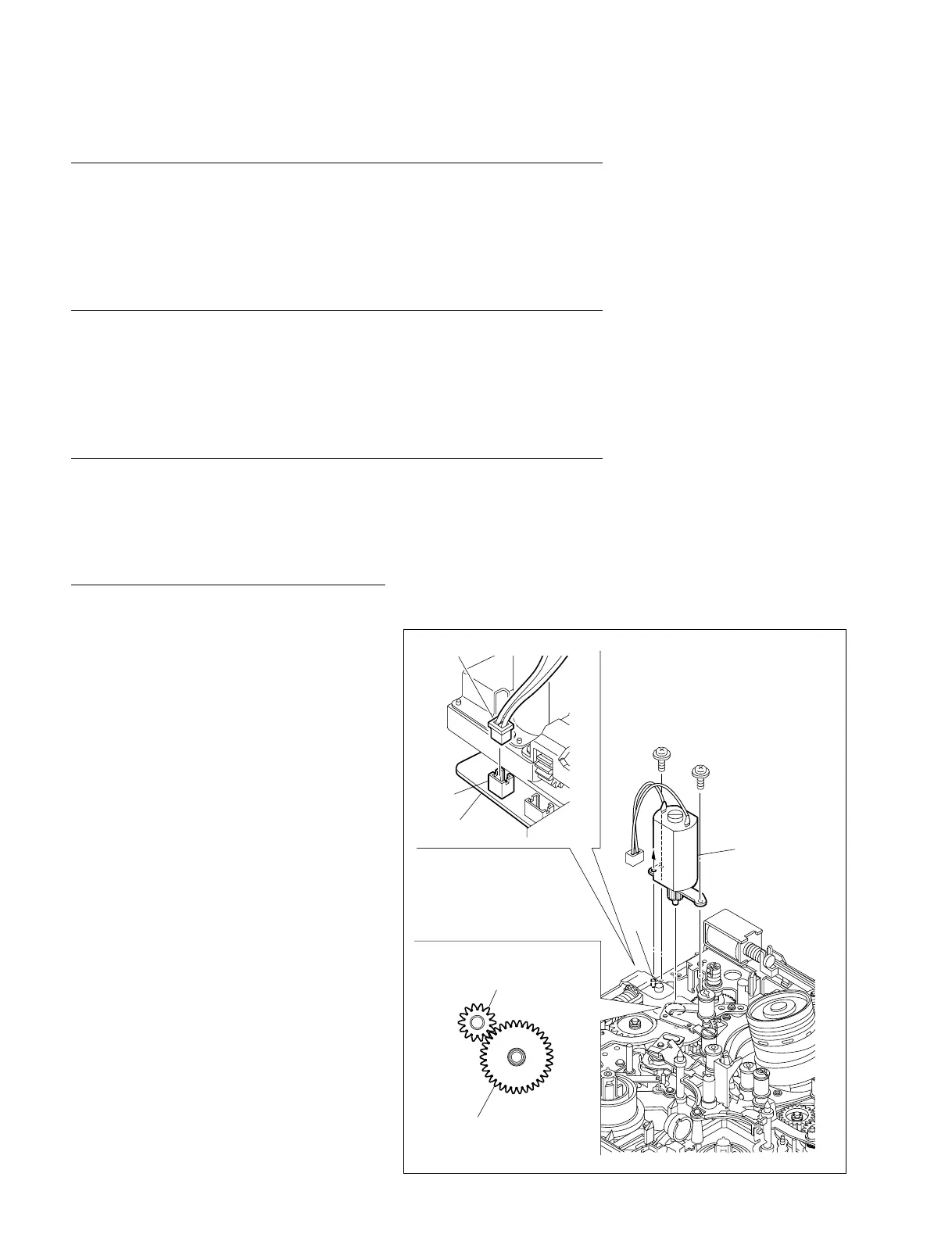

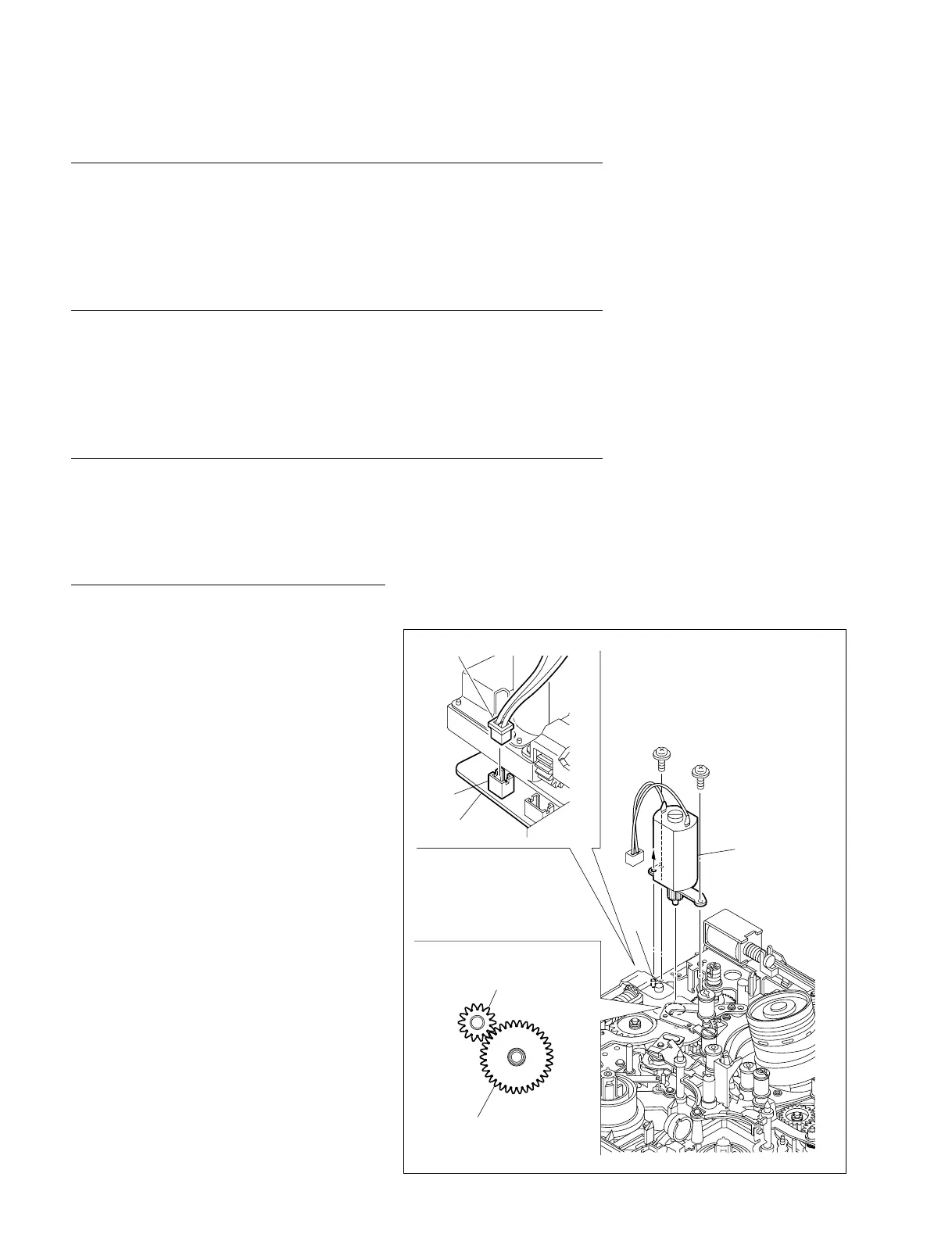

1. Disconnecting the connector

Disconnect the harness from the connector

(CN19) on the MS-64 board with tweezers.

2. Replacing the loading motor assembly

(1) Remove the two screws to remove the

loading motor assembly.

(2) Align a positioning hole in a new loading

motor with the positioning pin on the MD

chassis and engage the motor gear with the

FG gear.

(3) Fix the loading motor assembly with the two

screws.

Tightening Torque : 0.1 N.m {1 kgf.cm}

3. Reconnecting the connector

Reconnect the harness to the connector (CN19)

on the MS-64 board with tweezers.

P1.4 x 3.5

P1.4 x 3.5

Loading motor

assembly

Pin

MS-64 board

CN19

Harness

Motor gear

FG gear assembly

Loading...

Loading...