ENGINE GENERAL INFORMATION AND DIAGNOSIS (H27 ENGINE) 6-1-109

DTC CONFIRMATION PROCEDURE

1) Connect scan tool to DLC with ignition switch OFF.

2) Turn ON ignition switch and clear DTC, pending DTC and freeze frame data by using scan tool and warm up

engine completely.

3) Run engine at idle speed for 1 min.

4) Check pending DTC by using scan tool.

TROUBLESHOOTING

NOTE:

Check to make sure that following condition is satisfied when using this “DTC CONFIRMATION PRO-

CEDURE”.

• Intake air temp. : – 8°C (18°F) or higher

• Engine coolant temp. : – 8 – 110°C (18 – 230°F)

• Altitude (barometric pressure) : 2400 m, 8000 ft or less (560 mmHg (75 kPa) or more)

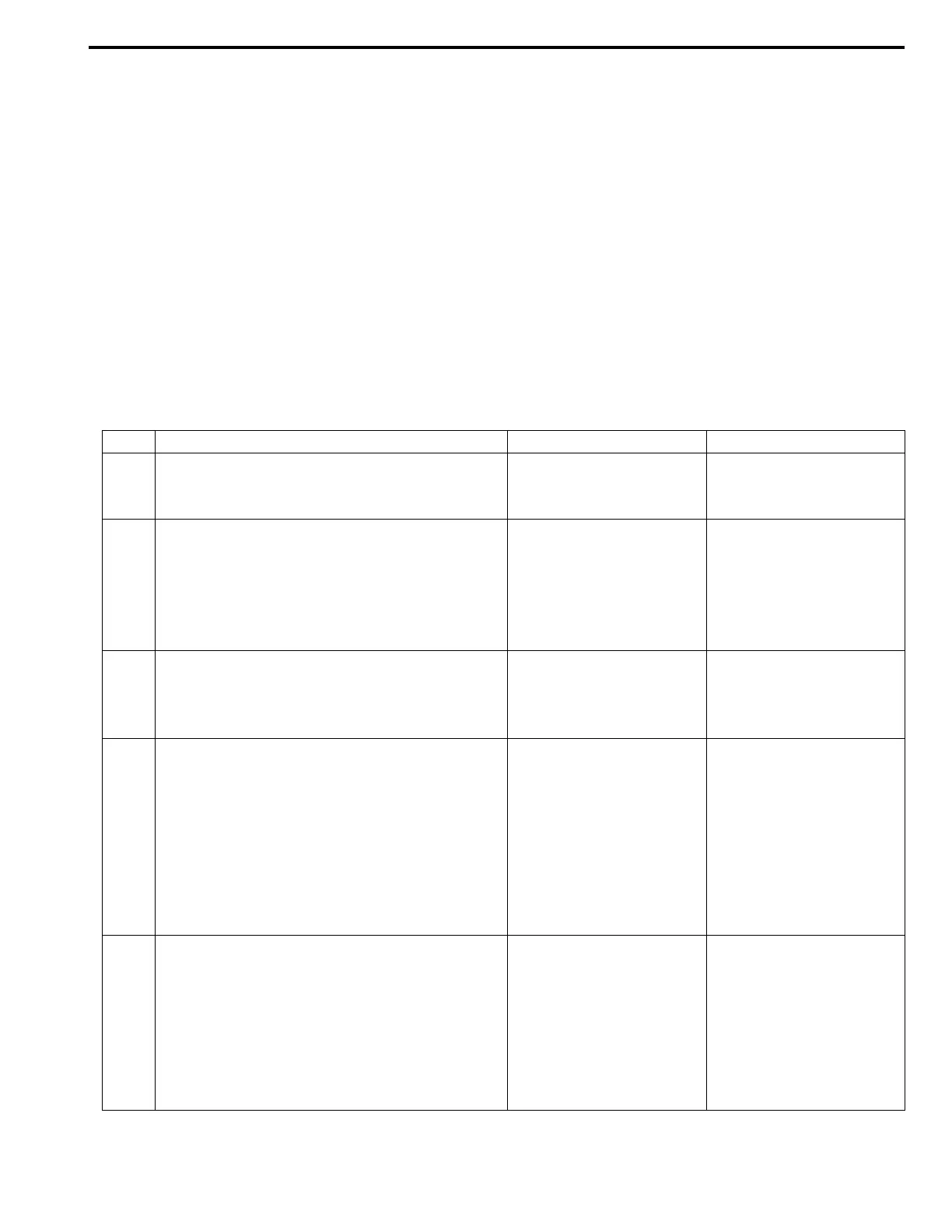

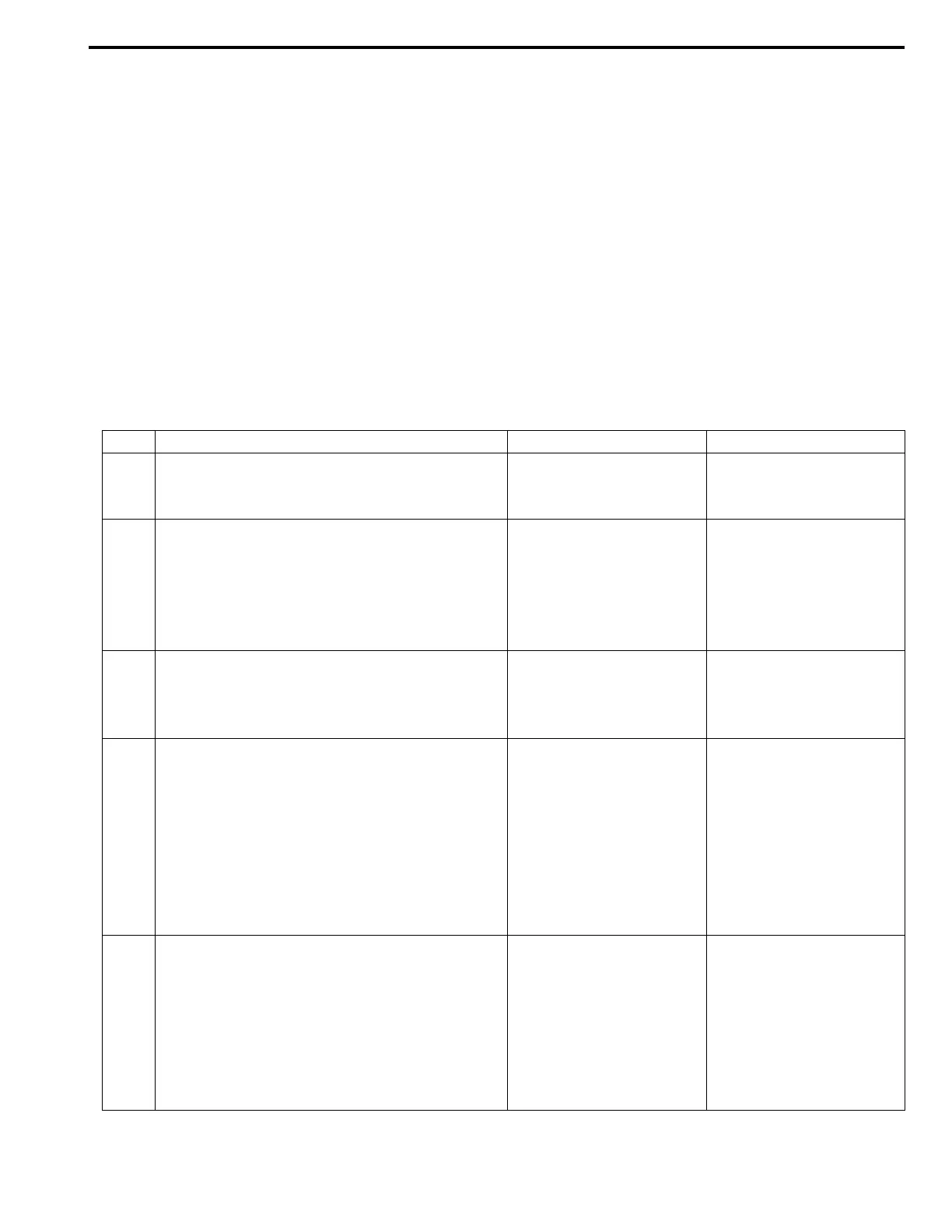

Step Action Yes No

1Was “ENGINE DIAG. FLOW TABLE” per-

formed?

Go to Step 2. Go to “ENGINE DIAG.

FLOW TABLE” in this

section.

2 Idle speed check:

1) Check engine idle speed referring to “IDLE

SPEED/IDLE AIR CONTROL DUTY

INSPECTION” in Section 6E2.

Is engine idle speed within specification?

Intermittent trouble or

faulty ECM (PCM).

Check for intermittent

referring to “INTERMIT-

TENT AND POOR CON-

NECTION” in Section 0A.

Go to Step 3.

3 IAC valve check:

1) Check IAC valve referring to “IAC VALVE

INSPECTION” in Section 6E2.

Is check result as specified?

Go to Step 6. Go to Step 4.

4 IAC valve circuit check:

1) With ignition switch OFF, disconnect ECM

(PCM) couplers.

2) Check for proper connection to IAC valve at

C51-1-4, C51-1-5, C51-1-16 and C51-1-17

terminals.

3) If OK, check resistance between C51-1-4

and C51-1-5, C51-1-16 and C51-1-17.

Is each resistance 51 – 67 Ω?

Go to Step 5. “LT GRN/BLK”, “PPL/

BLK”, “GRY/BLU” or

“PPL/YEL” wire open or

short.

If wire and connections

are OK, replace IAC

valve.

5 IAC valve power supply voltage check:

1) Connect ECM (PCM) couplers.

2) With ignition switch OFF, disconnect C29

coupler of IAC valve.

3) With ignition switch ON, check voltage

between C29-2 and ground, C29-5 and

ground.

Is each voltage 10 – 14 V?

IAC valve or ECM (PCM)

malfunction.

Open “BLU/BLK” wire.

Loading...

Loading...