DIFFERENTIAL (FRONT) 7E-3

Diagnosis

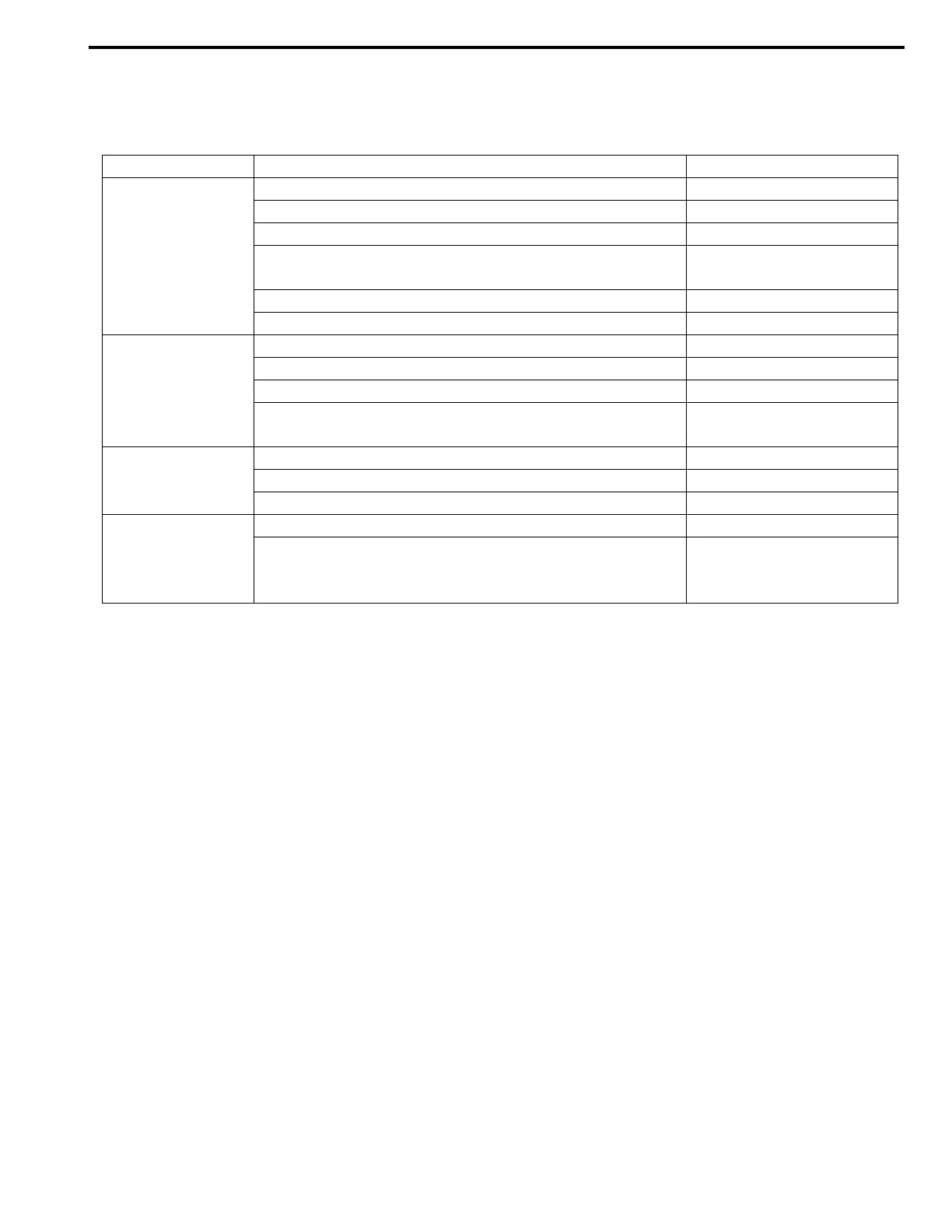

Differential Assembly Diagnosis Table

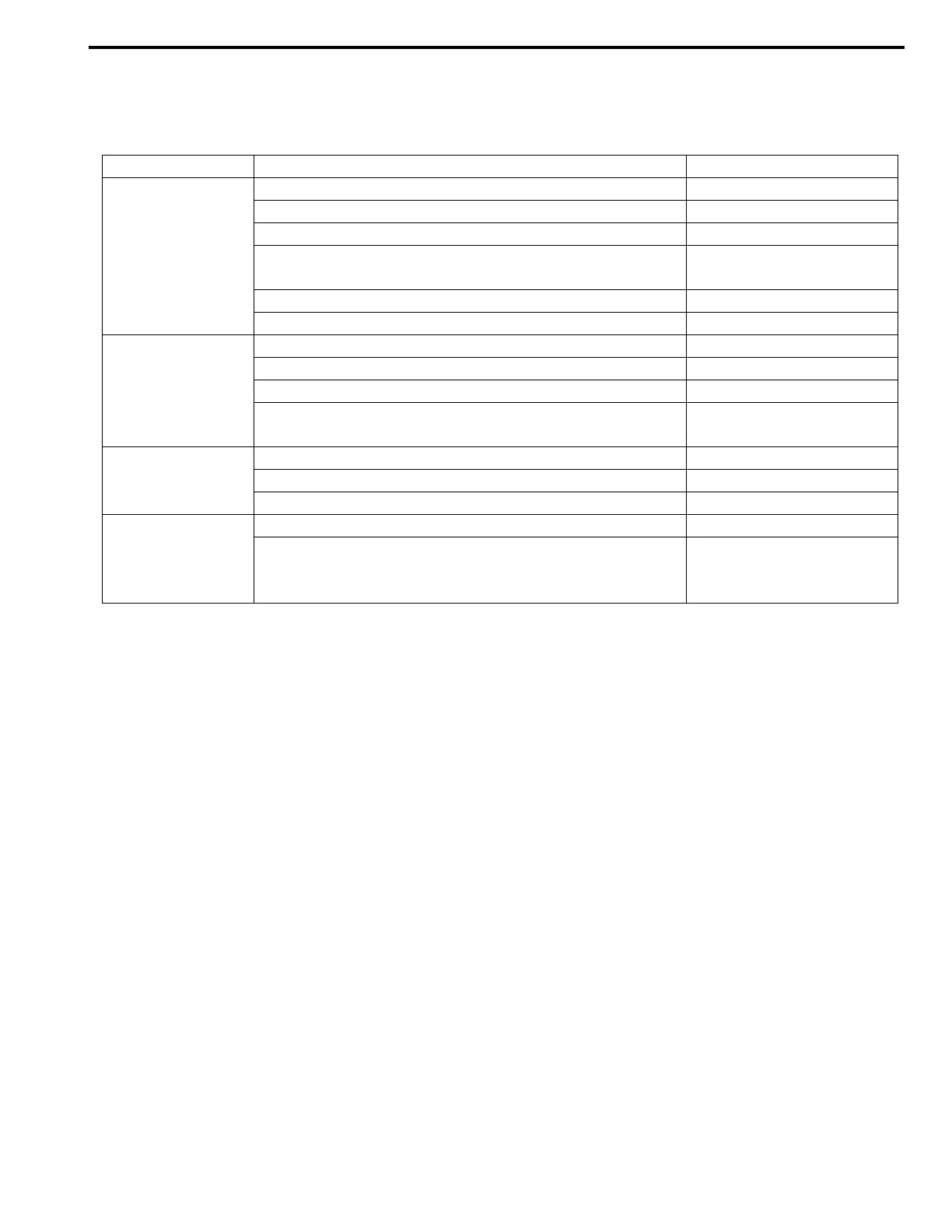

4WD Control System Diagnostic Flow Table

Before performing the trouble diagnosis, check that the transfer and front differential are in good condition and

there is no air leakage from air hoses and the actuator. Refer to “4WD CONTROL SYSTEM INSPECTION” in

this section for air leakage.

Notes on system circuit inspection

• Be sure to read “PRECAUTIONS FOR ELECTRICAL CIRCUIT SERVICE” in Section 0A before circuit

inspection and observe what is written there.

• For system circuit, refer to the figure of “GENERAL DESCRIPTION” in this section.

• For terminal arrangement, refer to “4WD CONTROL CIRCUIT INSPECTION” in this section.

Condition Possible Cause Correction

Gear noise Deteriorated or water mixed lubricant Repair and replenish.

Inadequate or insufficient lubricant Repair and replenish.

Maladjusted backlash between bevel pinion and gear Adjust.

Improper tooth contact in the mesh between bevel pinion

and gear

Adjust or replace.

Loose bevel gear securing bolts Replace or retighten.

Damaged side gear(s) or side pinion(s) Replace.

Bearing noise (Constant noise) Deteriorated or water mixed lubricant Repair and replenish.

(Constant noise) Inadequate or insufficientlubricant Repair and replenish.

(Noise while coasting) Damaged bearing(s) of bevel pinion Replace.

(Noise while turning) Damaged differential side bearing(s)

or axle bearing(s)

Replace.

Oil leakage Worn or damaged oil seal Replace.

Excessive oil Adjust oil level.

Loose differential carrier bolts Replace or retighten.

2WD/4WD

switching error

Defective actuator Replace.

Abnormality in 4WD control system Inspect referring to “4WD

CONTROL SYSTEM DIAG-

NOSTIC FLOW TABLE”.

Loading...

Loading...