0B-2 Maintenance and Lubrication:

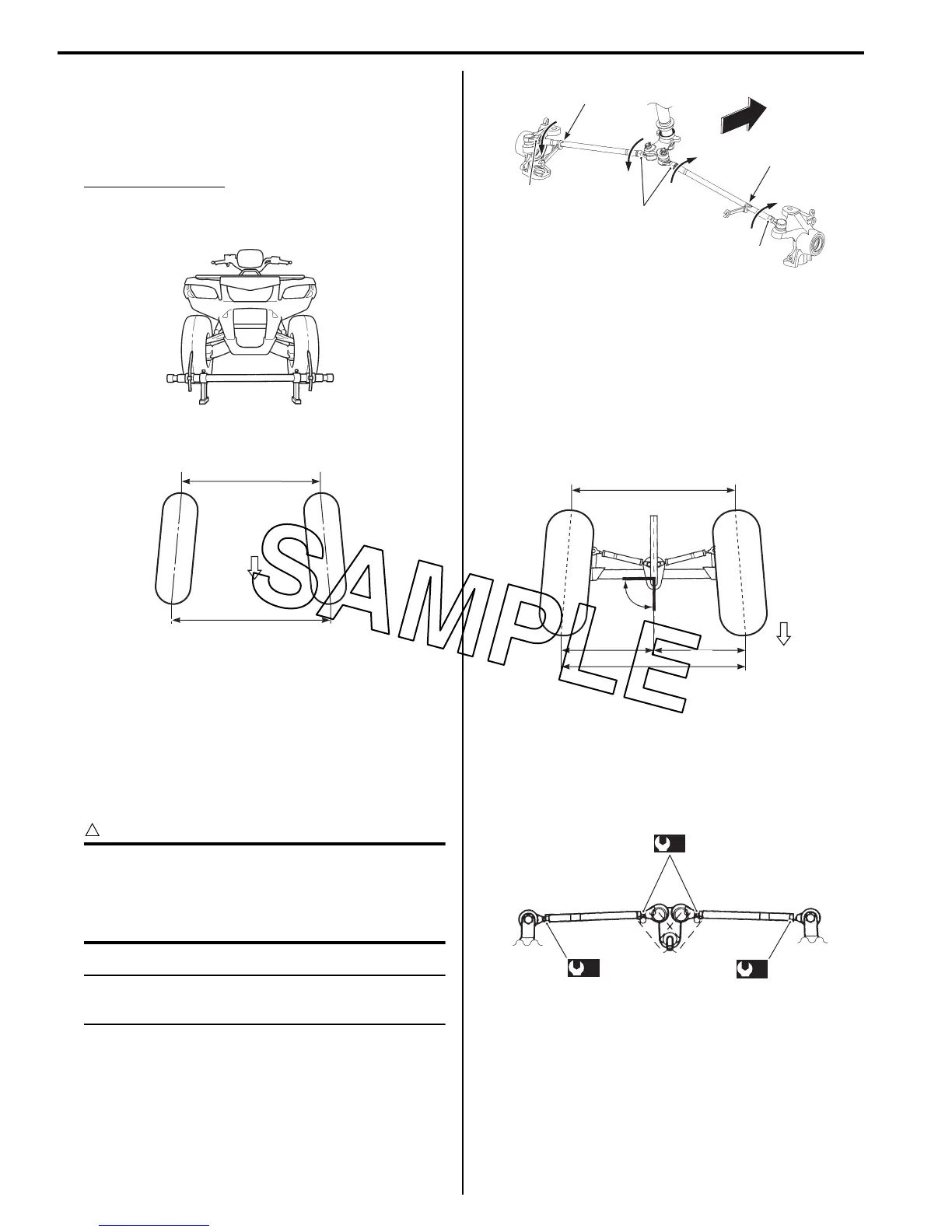

5) Measure the distances (“A” and “B”) between the

front wheels. Subtract the measurement of “A” from

that of “B” to find the toe-out. If the toe-out is not

within specification, adjust the tie-rod to the right or

left until the toe-out is within the specified range.

Toe-out (“B” – “A”)

Standard: 5 ± 4 mm (0.20 ± 0.16 in)

If the toe-out is out of specification, bring it into the

specified range. Refer to “Toe Adjustment (LT-A750XP/

ZK9) (Page 0B-2)”.

Toe Adjustment (LT-A750XP/ZK9)

B931G30206031

Adjust the toe-out as follows:

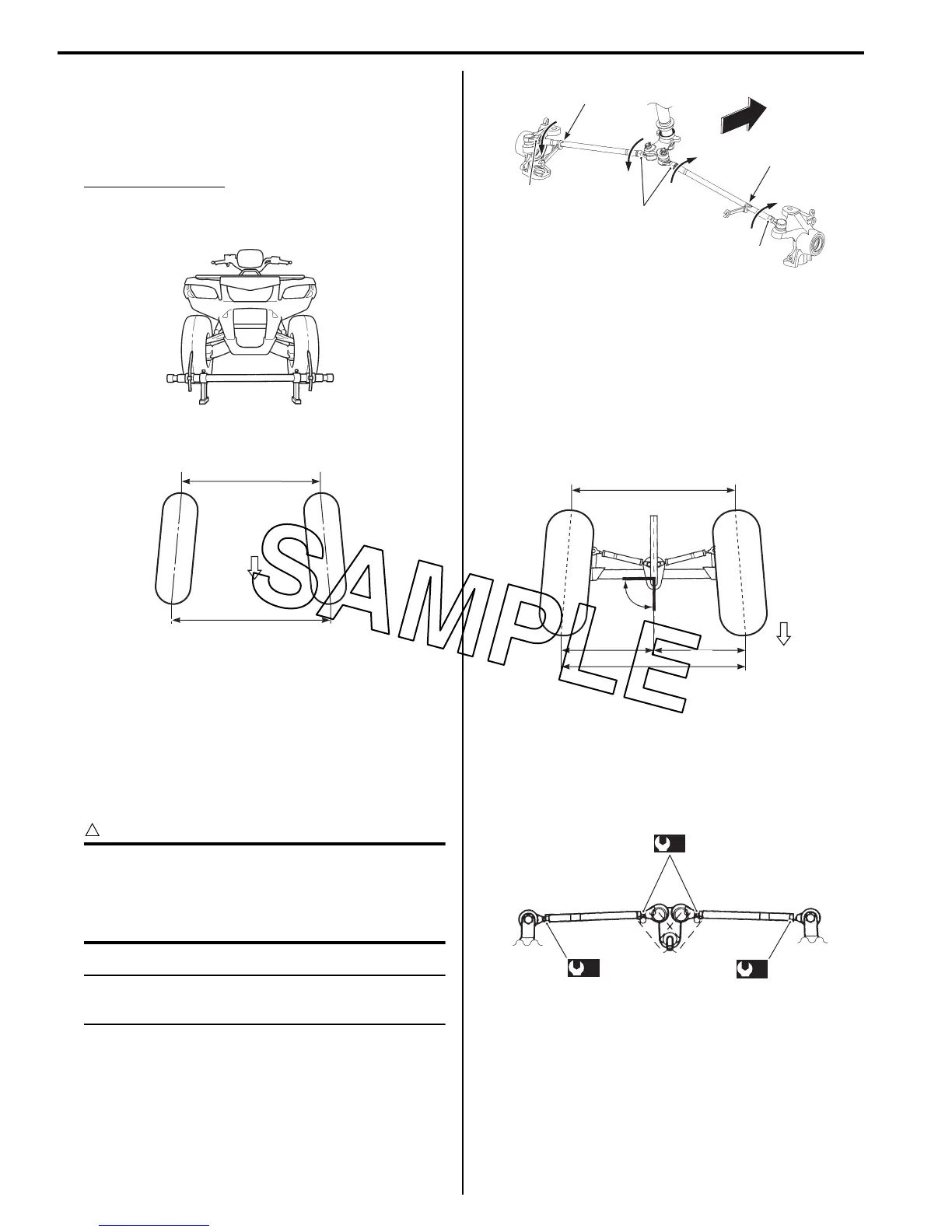

1) Loosen the lock-nuts (1), (2) on each tie-rod.

CAUTION

!

• The lock-nuts (2) have left-hand threads.

• When loosening and tightening the lock-

nuts, hold the tie-rod end with a open end

wrench.

NOTE

Hold the concave part “a” of tie-rod with a

wrench.

2) Temporarily tighten the four lock-nuts.

3) Check that the distances “C” and “D” are equal, as

shown. If the distances are not equal, adjust the tie-

rod to the right or left until the toe-out is within

specification. Check the toe-out again by measuring

distances “A” and “B”.

4) If the toe-out is not within specification, repeat the

adjustment as above until the proper toe-out is

obtained and distances “C” and “D” become equal.

5) After adjustment has been made, tighten the four

lock-nuts to the specified torque.

Tightening torque

Tie-rod lock-nut (a): 29 N·m (2.9 kgf-m, 21.0 lbf-

ft)

I931H1020057-01

FWD

“A”

“B”

I831G1020059-04

2

1

1

“a”

“a”

FWD

I931H1020079-02

“C”

Right angle

(90

°

)

FWD

“A”

“B”

“D”

I831G1020088-04

(a)

(a)

(a)

I831G1020089-01

Loading...

Loading...