Part Two

activating PI control. If the SENSITIVITY setting is 60% (40% missing), the room pressure

(velocity) must be 40 ft/min off set point before PI control is activated. Conversely, if the

SENSITIVITY setting is 80% (20% missing), the room pressure (velocity) must only be 20 ft/min

off set point before PI control is activated. The default of 80% is usually a good compromise

between PID and integral control.

The SPEED menu item slows down the control output. The controller is shipped with a control

signal capable of rotating the damper 90 degrees in 1.5 seconds. This may be too fast if the

damper is in an unstable flow area (very near the exhaust fan), or there are competing air flows at

the room. Controllers modulating a VFD system will probably need to be slowed down, since the

control signal is substantially faster than the VFD/fan can respond.

The remaining menu items, Exh Kc Value, Sup Kc Value, Exh Ti Value and Sup Ti Value

should not be adjusted unless severe stability problems exist. Adjusting these variables may

improve the response and stability, but the exact opposite may happen causing the controller to

become unstable, hunt substantially, or have very slow response. If controller performance

cannot be improved by adjusting the SPEED and SENSITIVITY, the two menu items can be

manually set to their default values.

Maintenance and Repair Parts

The Model RPC30 PresSura Room Pressure Controller requires minimal maintenance. Periodic

inspections of system components as well as an occasional pressure sensor cleaning are all that

are needed to ensure that the PresSura controller is operating properly.

System Component Inspection

It is recommended that the pressure sensor be periodically inspected for accumulation of

contaminants. The frequency of these inspections is dependent upon the quality of the air being

drawn across the sensor. Quite simply, if the air is dirty, the sensors require more frequent

inspection and cleaning.

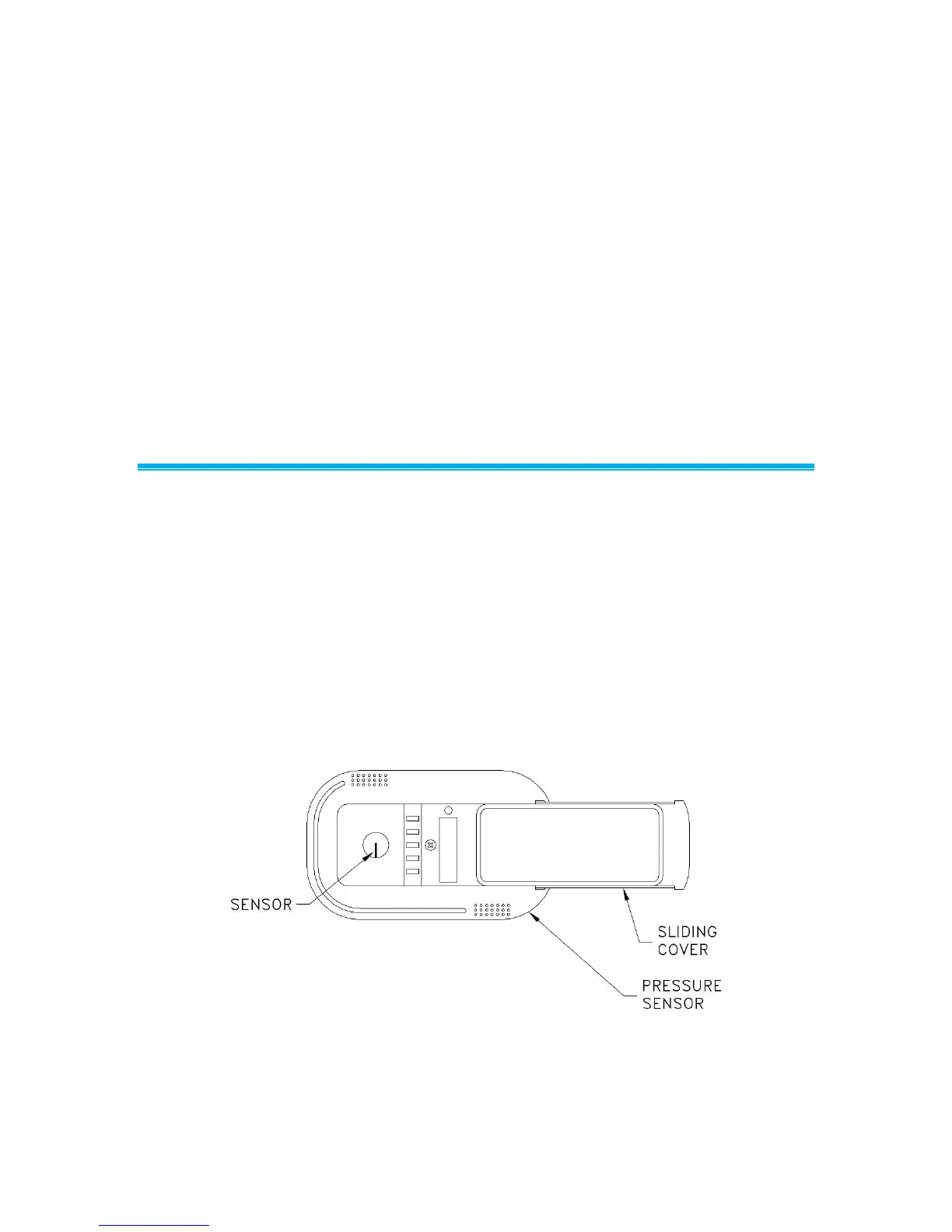

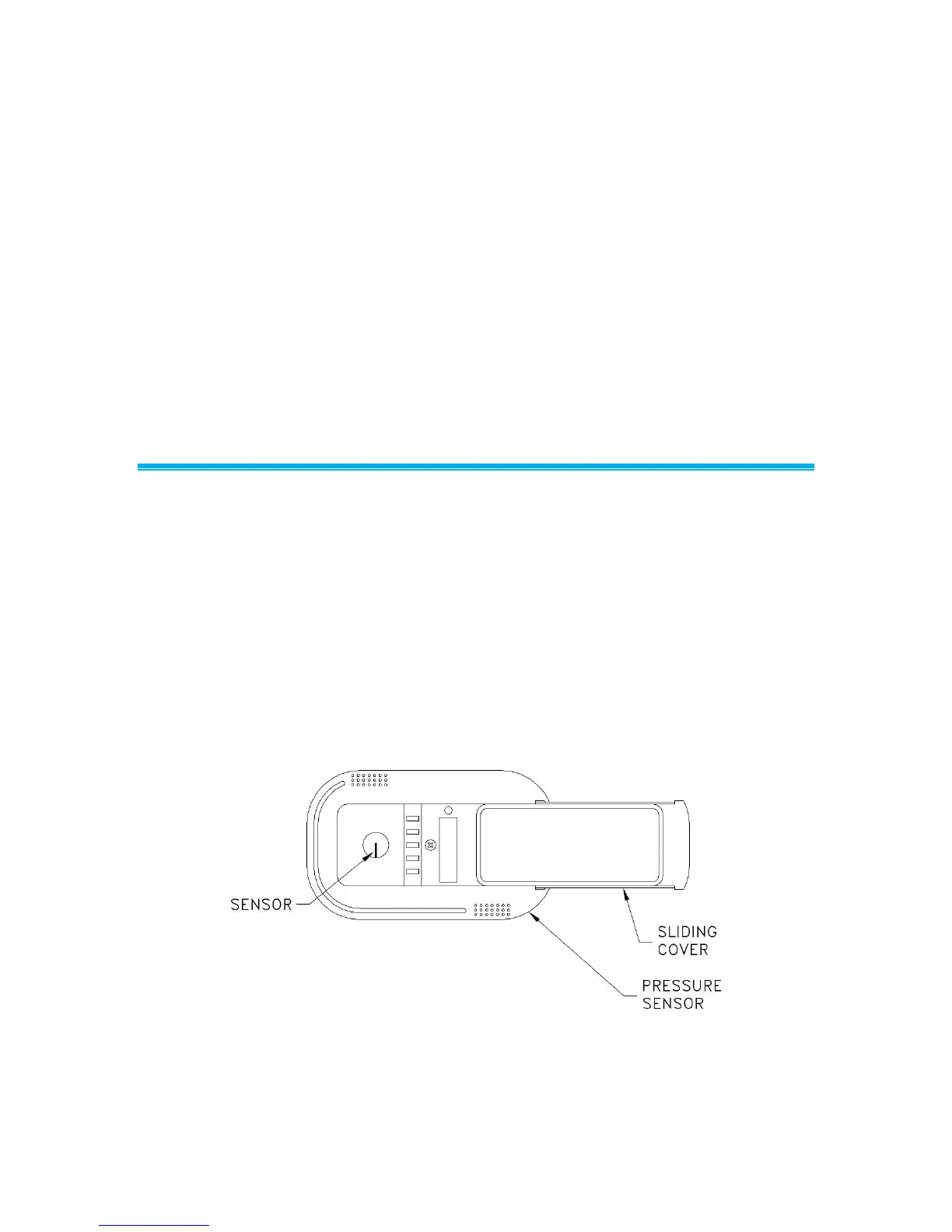

Visually inspect the pressure sensor by sliding open the sensor housing door (Figure 12). The air

flow orifice should be free of obstructions. The small ceramic coated sensors protruding from the

orifice wall should be white and free of accumulated debris.

Figure 12: Pressure sensor door slid open

Periodically inspect the other system components for proper performance and physical signs of

excessive wear.

Loading...

Loading...