3-60 OM 28Z3 US – Edition 2.0 * * 28Z3b340.fm

Operation

3.31 Hydraulic quickhitch (option)

Caution!

Before putting this feature into operation, specific training must be performed

by authorized technical staff and must be understood by the operator. For

reasons of safety, the quickhitch must be operated with two control elements!

This avoids opening the quickhitch unintentionally during work operation.

Maintenance

Important!

Before picking up an attachment, the operator must make sure it can be hitched

correctly by removing all dirt on either claw of the quickhitch.

Perform maintenance on the quickhitch system once a day with the other mainte-

nance work for the machine.

Perform visual checks for possible defects, damage or cracks.

Remove all dirt on and around moving parts.

The claws must be clean and slightly greased.

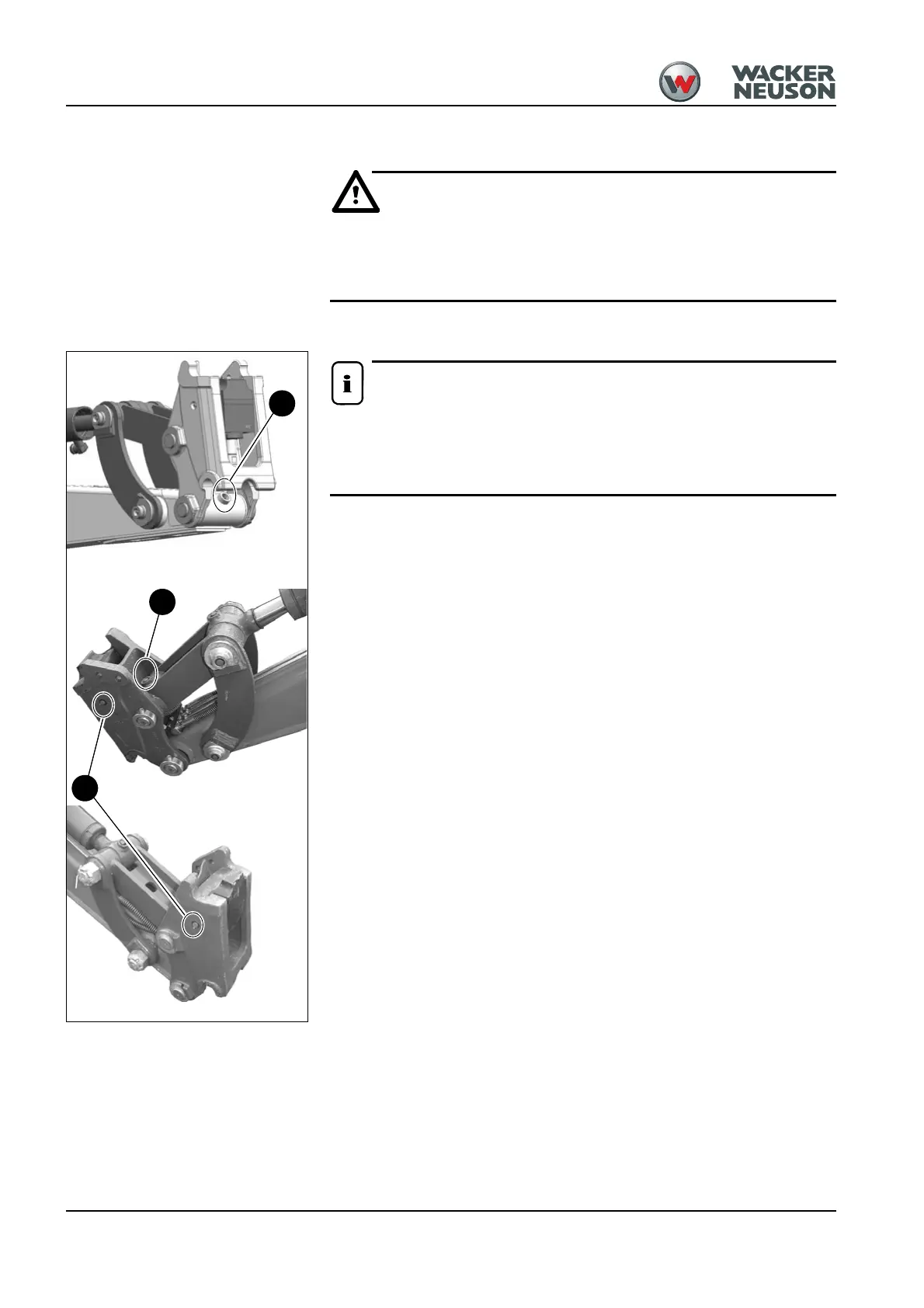

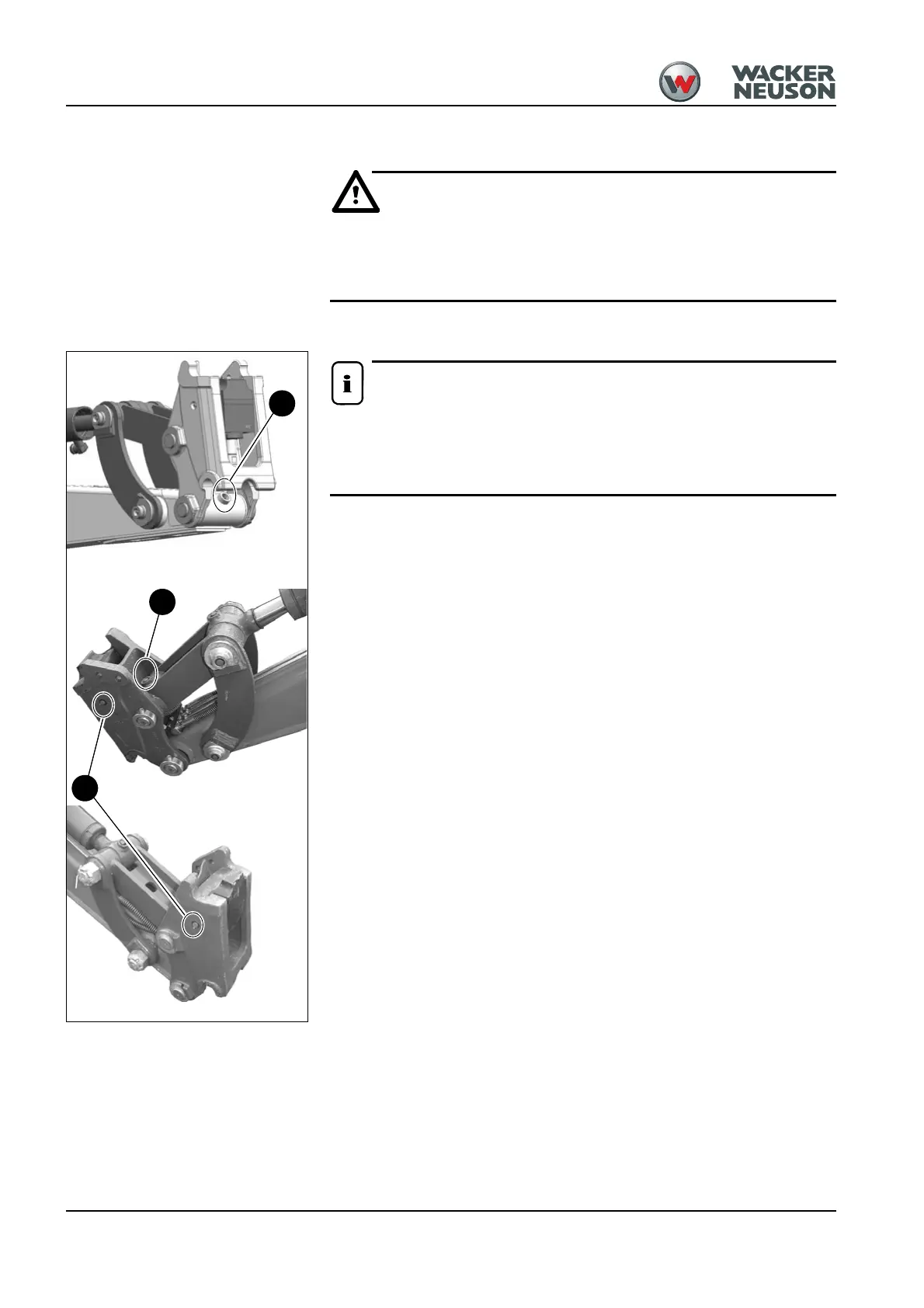

Apply grease to the pins via grease nipples S.

Apply grease to the friction surfaces of the lock mechanism via 2 further grease nipples N

on either side of the quickhitch (see Fig. 80).

Before starting work, check the acoustic signal which must be audible when pressing

switch B.

Fig. 80: Lubrication

S

S

N

Loading...

Loading...