OM 28Z3 US – Edition 2.0 * 28Z3b530.fm 5-24

Maintenance

Adjusting the track tension

Caution!

Projectile hazard.The grease fitting for track adjustment is subject to high pressure.

The grease fitting can become a projectile if pressure caused by track tension is not

properly relieved..

• Do not remove the grease fitting.

• Wear safety goggles, gloves and protective clothing to reduce skin exposure to

grease. Wipe grease from skin and seek immediate attention if grease contacts

eyes.

• When relieving the pressure in the track tension system, do not turn the grease

fitting farther than one counter-clockwise turn.

• Do not loosen any part of the track tension system until the pressure has been

released from the track tension system.

• Keep your face away from the lubricating valve connection..

• Do not use auxiliary force on the track or idler in an effort to force grease from the

loosened fitting. Contact your Wacker Neuson dealer and wait for a qualified

technician to determine the problem and how to solve it..

NOTICE

Possibility of equipment damage. Excessive tension of the tracks causes

severe damage to the ram and the track.

• Tighten the tracks only up to the prescribed measuring distance.

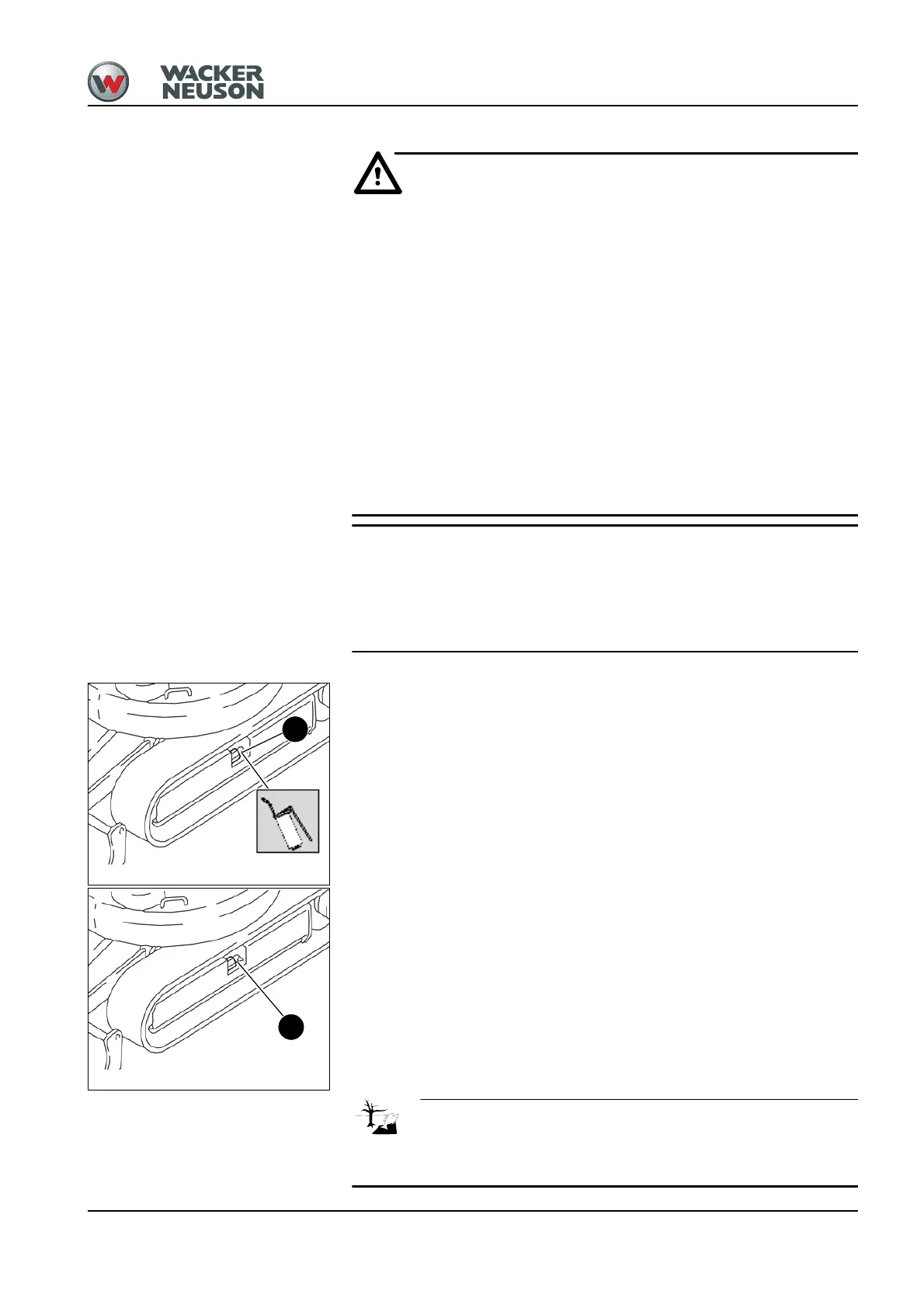

Tightening the tracks

☞ Inject grease with the pump through lubricating valve.

☞ Check the tension is correct by starting the engine, letting it run at idling speed and slowly

moving the machine forward and reverse and switching it off again.

☞ Check the tension of the track tracks again .

➥ If it is not correct:

☞ Adjust again.

☞ Contact your Wacker Neuson dealer if the procedure for tightening the tracks does not correct

the track tension.

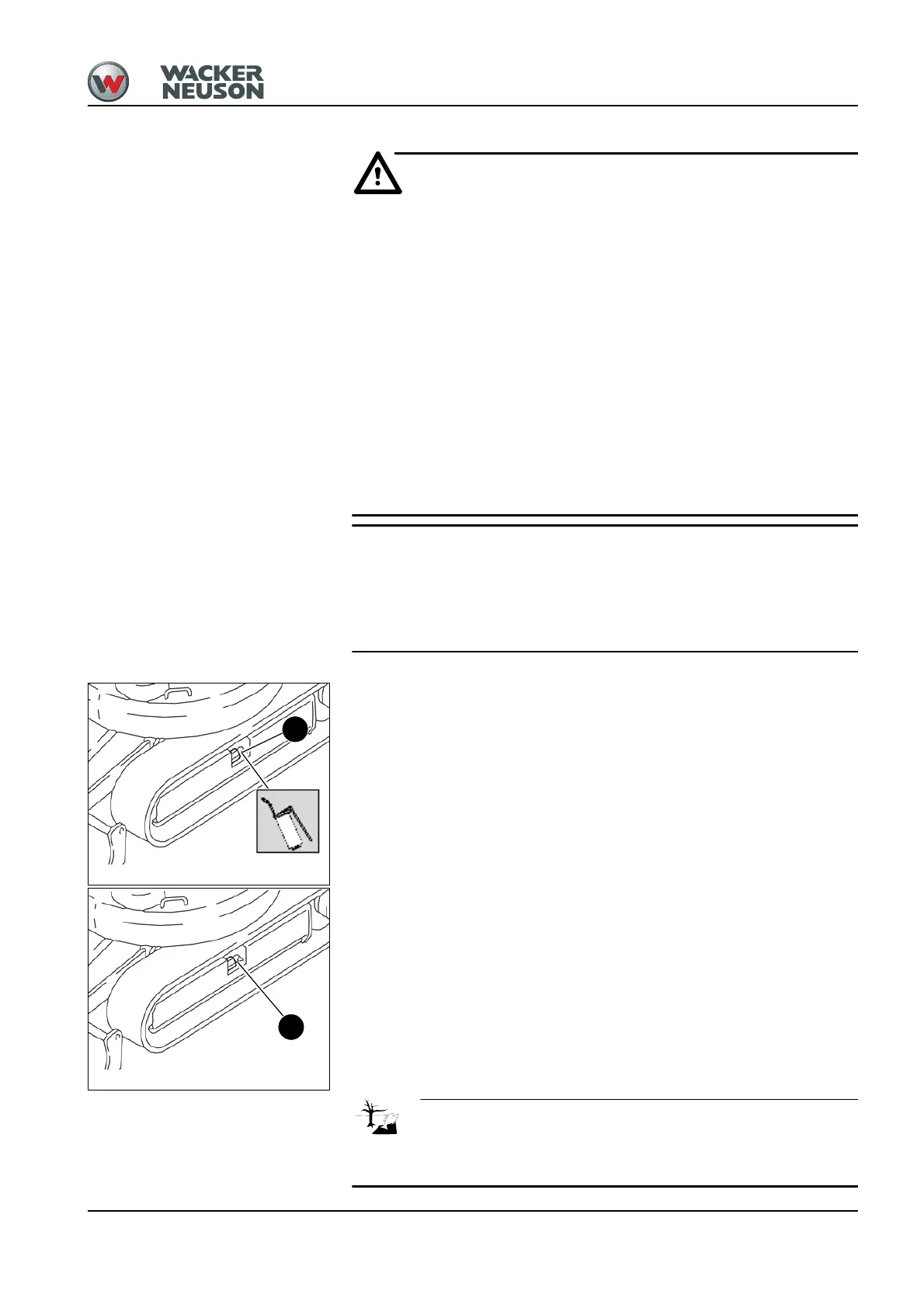

Reducing tension

• Drain the grease as described below. Do not drain it in any other way. Also bear in mind the

safety instructions on this page.

☞ Slowly open the lubricating valve A by 1 turn to allow the grease to flow out.

☞ Place a suitable container underneath to collect the grease.

➥ The grease flows out of the groove of the lubricating valve.

☞ Retighten the lubricating valve A.

☞ Check the tension is correct by starting the engine, letting it run at idling speed and slowly

moving the machine forward and reverse and switching it off again.

☞ Check the tension of the track tracks again .

➥ If it is not correct:

☞ Adjust again.

Environment!

Use a suitable container to collect the grease as it flows out and dispose of it in an environ-

mentally friendly manner.

Fig. 132: Tightening the tracks

A

Fig. 133: Draining grease

A

Loading...

Loading...