OM 28Z3 US – Edition 2.0 * 28Z3b520.fm 5-17

Maintenance

Environment!

Collect drained hydraulic oil and biodegradable oil in a suitable container!

Dispose of drained oil and used filters by an ecologically safe method.

Always contact the relevant authorities or commercial establishments in charge of oil dis-

posal before disposing of biodegradable oil.

Checking the hydraulic oil level

Warning!

Pressurized hydraulic oil hazard. Overfilling the hydraulic system with

hydraulic oil can lead to high pressures and escaping hydraulic oil. This escap-

ing hydraulic oil can cause severe injury.

• Do not overfill the hydraulic system.

☞ Proceed as follows:

• Park the machine on level ground.

• Retract the bucket and boom hydraulic cylinders, lower the boom and the bucket

teeth to the ground.

• Lower the stabilizer blade to the ground.

• Straighten the boom.

• Stop the engine.

• Fold the control lever base up.

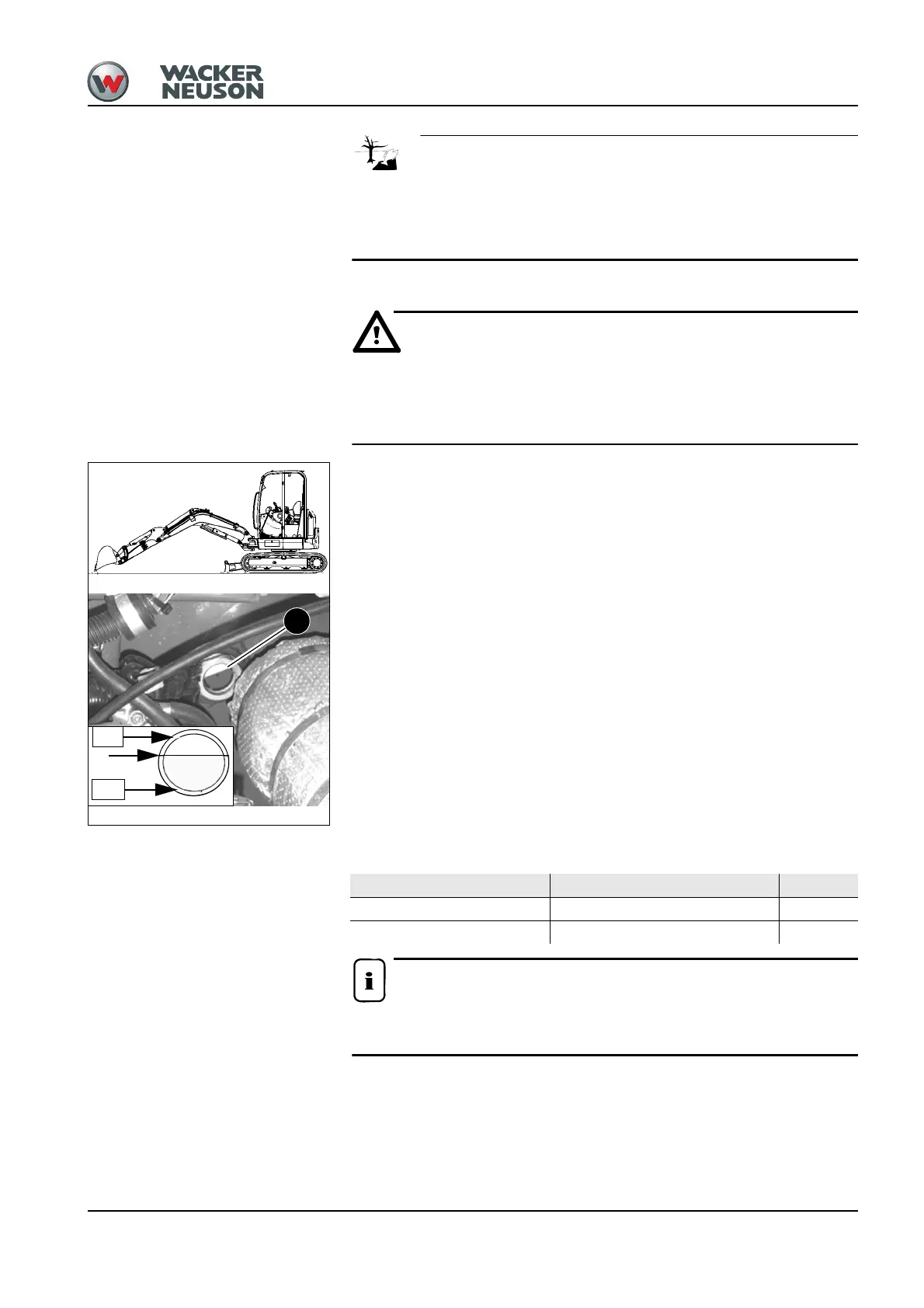

• Sight glass B is located in the rear left corner of the machine in the trim.

• Check the oil level on sight glass B.

• The oil level must be about 1 cm (0.4’’) over the center, between positions MIN and

MAX, as shown by the arrows in fig. 126.

➥ The MIN level is marked by the lower joint.

➥ The MAX level is marked by the upper joint.

If the oil level is lower

• Add hydraulic oil.

The oil level varies according to the machine's operating temperature:

Important!

Measure the oil level of the hydraulic system only after the machine reaches its

operating temperature.

Fig. 126: Oil level indicator on the hydraulic oil reservoir

B

Fig. 126: Parking the excavator

MIN

MAX

Machine condition Temperature Oil level

• Before putting into operation

Between 10 and 30 °C (50 and 86°F) LOW mark

• Normal operation

Between 50 and 90 °C 122 and 194°F) FULL mark

Loading...

Loading...