Foreword

Loading and transporting

BA RD24_RD28 en us 06

31

Machine parameters

Weight of machine [t] 1.5 t < m < 5.7 t

Area of center of gravity [mm] X

CoG

= 778 - 1048

Y

CoG

= 428 - 753

Z

CoG

= 650 - 1030

Identification reference point: Centre drum, front left

Interface parameters:

Type of contact: Non-skid

material

Frictional force [μ]: 0.6

Heavy load capacity: yes

Contact points: under contact pair

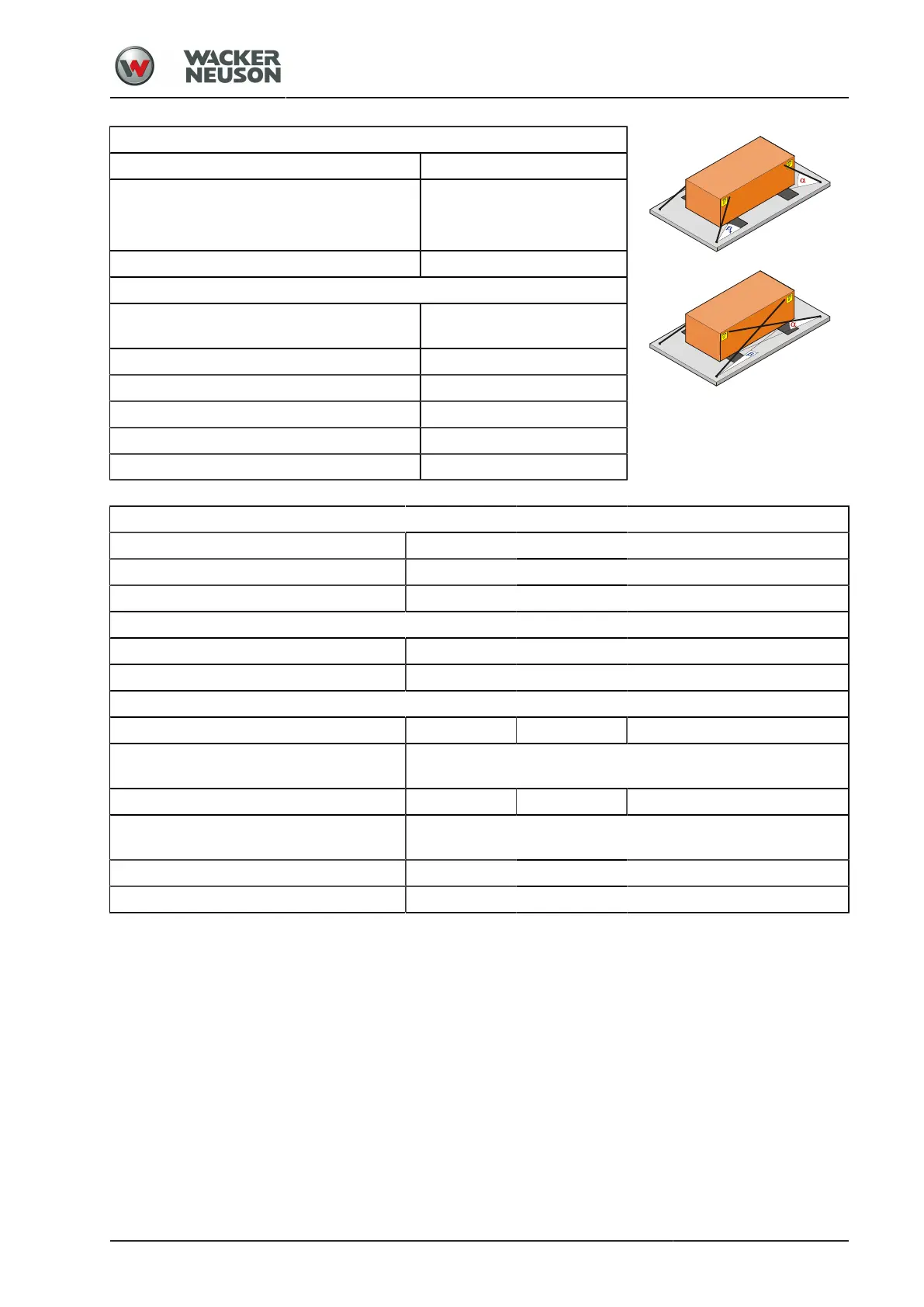

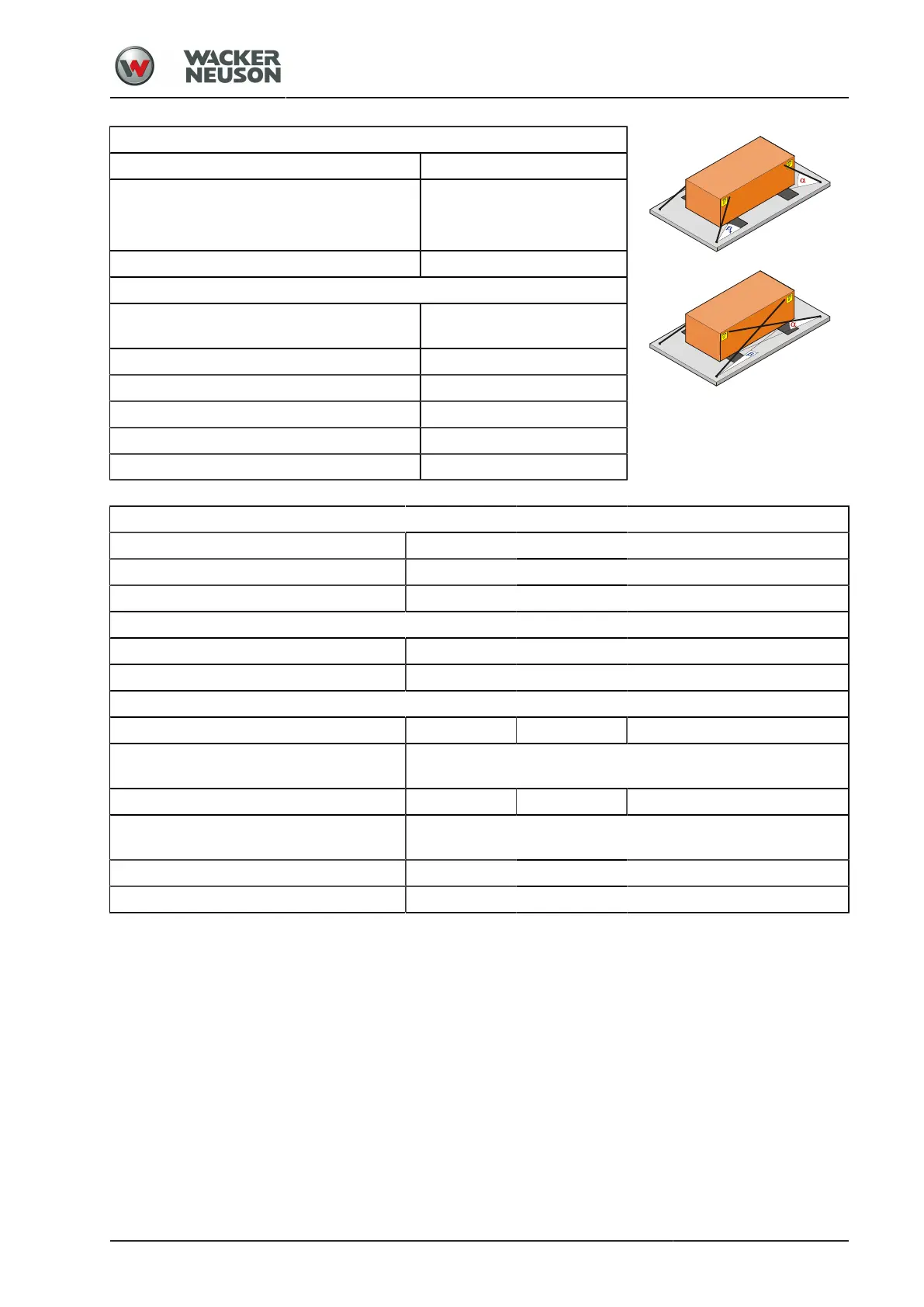

Vertical lashing angle α: 30° < α < 50°

Longitudinal, horizontal angle βx: 15° < βx < 40°

Specification of attachment points on the load:

Tensile capacity of lashing point [daN]: 2000

Marking of lashing point: Symbol ISO 6405-1

Number of lashing points: 4

Specification of lashing points on the means of transport:

Tensile capacity of lashing point [daN]: ≥ 2000

Number of lashing points: 4

Load securing equipment:

Wedge blocks: no Quantity: 0 Miscellaneous:

Other types of blocking: Positive blocking longitudinally / transversely to the direction of

travel

Lashing equipment capacity [daN]: 2000 Quantity: 4 Miscellaneous:

Recommended type of lashing equip-

ment:

Chain (6/8 2200 daN),

Belt (2000 daN) as an alternative

Connecting pieces to the lashing point: Hook with safety latch

Specific safety instructions

■

Drive the machine slowly onto the loading area in working speed, using the medium speed setting of

the diesel engine (ECO or 2/3).

■

Observe maximum permissible ramp slope (28.5 %, approx. 16°)

■

Secure the clamping devices

■

On rubber wheeled rollers with tyre filling system, the tyre filling system must be set to 0.6 MPa (6 bar,

87 psi).

■

Check the inflation pressure at least every 24 hours and, if refill the air, if necessary.

Miscellaneous:

■

Slot in the seat console, close the cabin doors

Loading...

Loading...